SF6 plasma isotropic etch for Si - NanoLabStaff/nanolab GitHub Wiki

by Marek Vlk ([email protected])

-

Apply etch mask

I used e.g. ma-P1275 spincoat at 7000 rpm for 30 s bake at 105 ºC for 6 min (hotplate) expose 400 mJ/cm2 with 405 nm (MLA-150) develop at ma-D332 for 1 min -

Chamber clean

O2 plasma cleaning for 5 min if necessary -

Chamber condition

Not used -

Insert sample

Sapphire carrier (4" wafer) Attach the sample with **Fomblin oil** to the carrier -

Strike !!! High pressure and ICP power are essential for high undercut etch rate. However, the plasma needs to strike at low ICP power and then gradually increase it. Changes to the pressure during processing quenched the plasma.

SF6: 100 sccm RF power: 50 W ICP power: 400 W, 10s -> 600 W, 10 s -> 1000 W, 10 s, -> 1500 W T = 20 ºC Helium pressure: 10 torr Chamber pressure: 50 mtorr -

Standard etch recipe:

SF6: 100 sccm RF power: 0 W ICP power: 1500 W T= 20 °C Helium pressure: 10 torr Chamber pressure: 50 mtorr Etch rate: Nonlinear for the undercut/lateral etching.

Photoresists (e.g. ma-P1275) are attacked by SF6 plasma, but can work with sufficient thicknesses. Depends on your needs. Nevertheless, the etching of the resist releases carbon into the plasma and causes contamination by carbon/flourocarbon deposits on the etched surfaces. Metal masks could be better alternatives, e.g. Al or Cr.

The samples are likely to heat up during long exposures to the plasma. This burns the resist in some cases, and could cause additional damage to the samples. Run the instrument in cycles where the plasma is off for a while to allow for cooling. E.g. 5 min etching, 3 min cooling (flush with N2 while cooling).

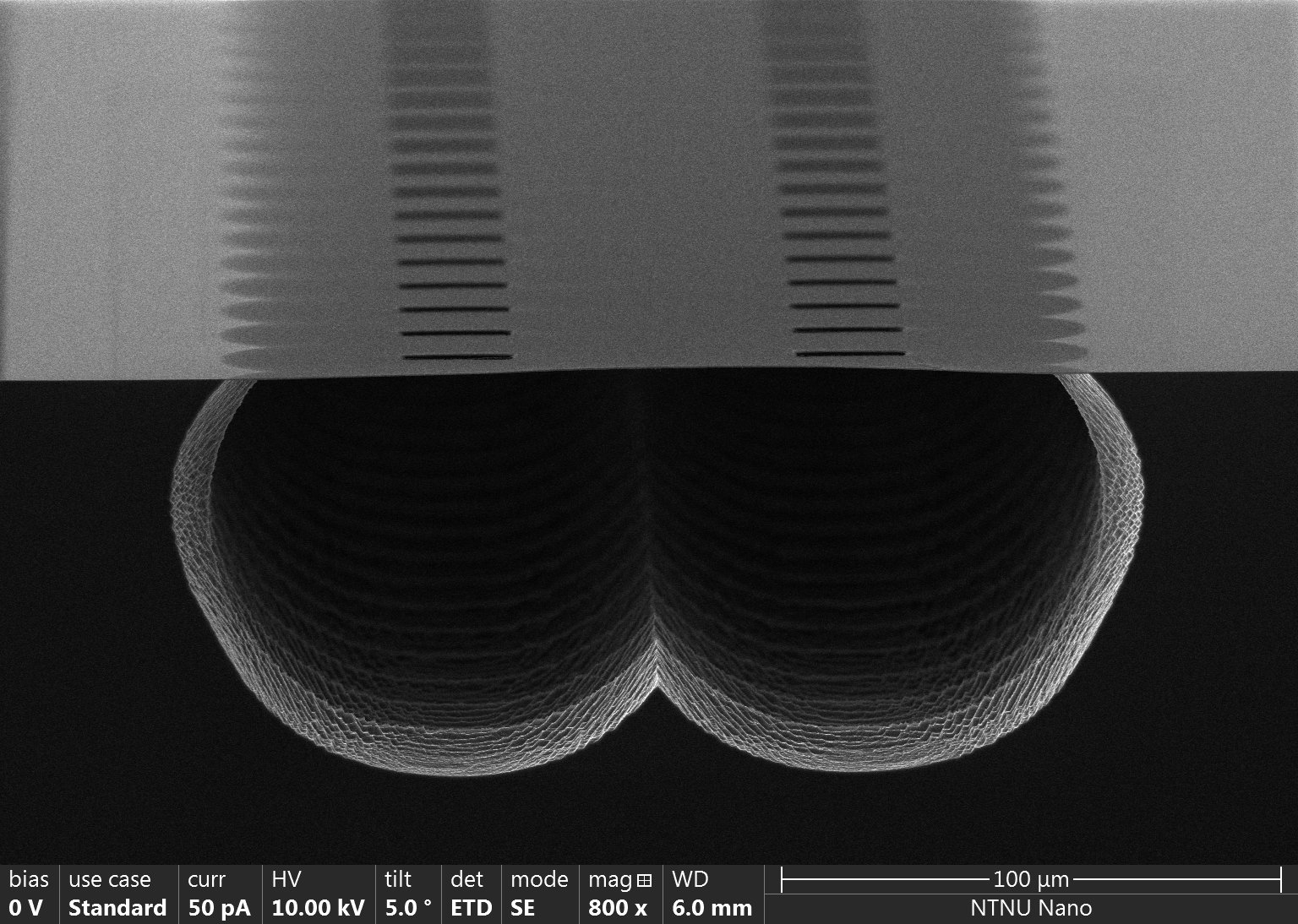

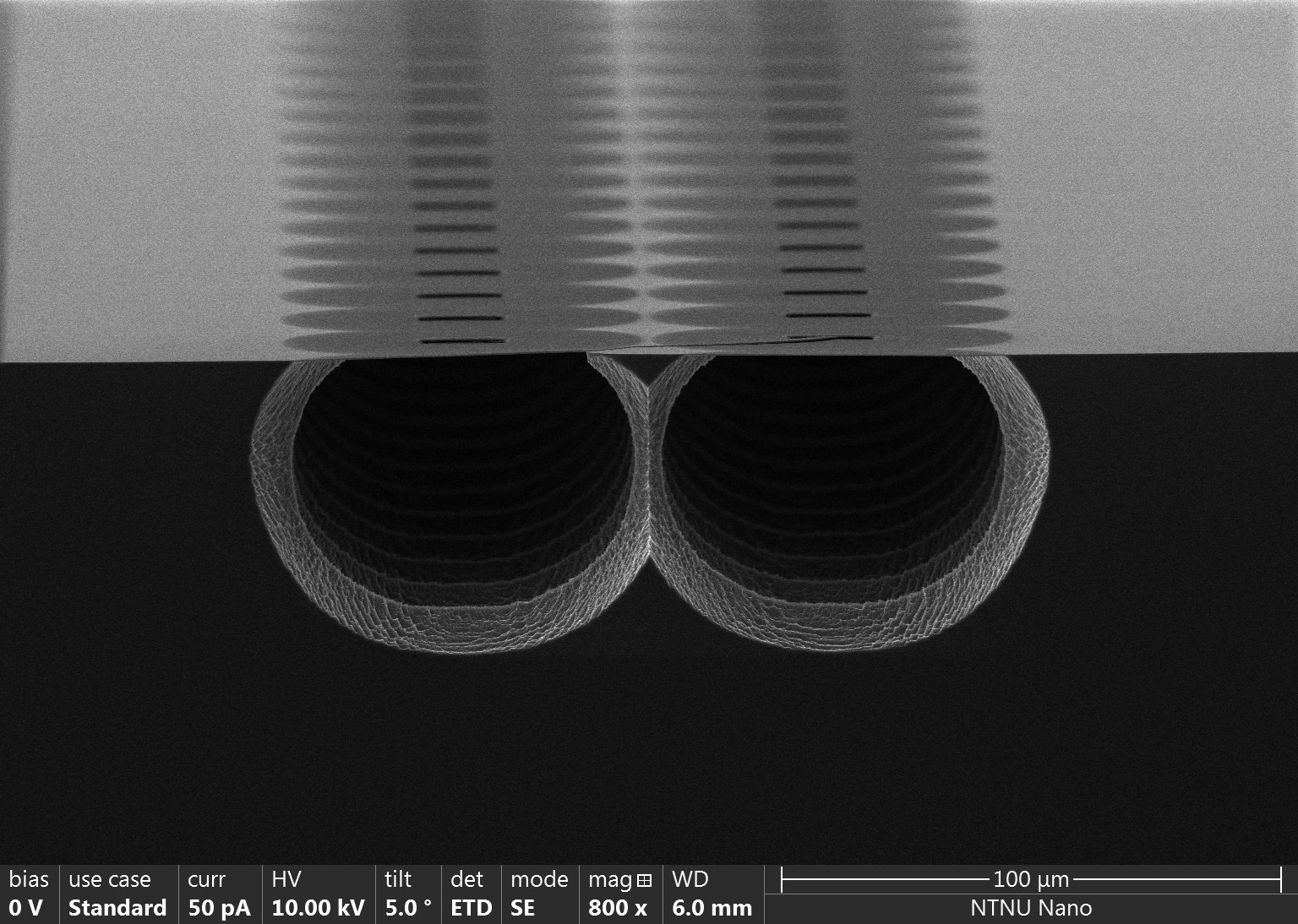

The following images show SiNx membranes with 2 rows of etching openings of 20x10 µm2 and 15x7.5 µm2 dimensions (WxL).