正面示意图 正面示意图

底面示意图 底面示意图

]DC Motor Driver HAT

标号 |

名称 |

功能描述 |

1 |

+ |

外接电源输入正极(7-12V) |

2 |

- |

外接电源输入负极 |

3 |

E1+ |

编码器E1正极 |

4 |

E1- |

编码器E1负极 |

5 |

E1A |

编码器E1 A相输出 |

6 |

E1B |

编码器E1 B相输出 |

7 |

M1+ |

电机M1正极 |

8 |

M1- |

电机M1负极 |

9 |

M2- |

电机M2负极 |

10 |

M2+ |

电机M2正极 |

11 |

E2B |

编码器E2 B相输出 |

12 |

E2A |

编码器E2 A相输出 |

13 |

E2- |

编码器E2负极 |

14 |

E2+ |

编码器E2正极 |

|

|

|

尺寸图 尺寸图

- 控制方式: I2C命令控制。

- 驱动信号:100Hz~12750Hz的PWM信号

- 编码器电机功能(仅限带编码器直流电机使用):

- 编码器使能/失能

- 减速比配置

- 获取编码器电机的转速

- 基本功能

- 设置驱动信号频率

- 设置占空比

- 设置电机正反转

- 调速

- PWM调速(频率一定,改变占空比大小,越大转速越快)

- 调频(改变驱动信号频率)

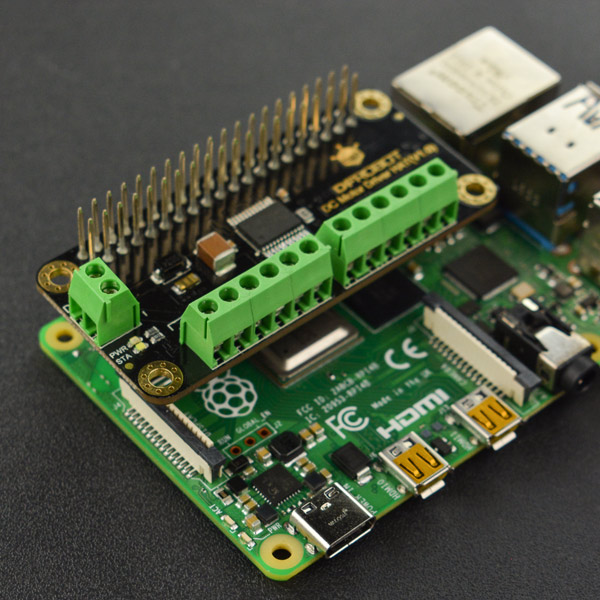

硬件

warning_yellow.png warning_yellow.png

|

注:额定工作电压在7~12V,电流不超过2A的直流电机均可! |

软件

接线图

step1:将DC Motor Driver HAT直插到树莓派主板上,连接电机板和电机,上电.

step2:检测I2C接口是否使能。输入命令i2cdetect -y 1,若未使能,会显示如下图所示提示:

step3:使能I2C接口。(若已开启可忽略此步)键入命令sudo raspi-config,进入配置界面,操作流程如下所示: step3:使能I2C接口。(若已开启可忽略此步)键入命令sudo raspi-config,进入配置界面,操作流程如下所示:

配置完成后,键入命令sudo reboot重启树莓派。

step4:检测I2C地址。键入命令i2cdetect -y 1检查设备I2C地址,如下图所示:

配置完成后,键入命令sudo reboot重启树莓派。

step4:检测I2C地址。键入命令i2cdetect -y 1检查设备I2C地址,如下图所示:

step5:下载DFRobot_RaspberryPi_Motor库。键入命令'sudo git clone https://github.com/DFRobot/DFRobot_RaspberryPi_Motor ,输入ls'查看命令,如下图所示:

step5:下载DFRobot_RaspberryPi_Motor库。键入命令'sudo git clone https://github.com/DFRobot/DFRobot_RaspberryPi_Motor ,输入ls'查看命令,如下图所示:

下载DFRobot_RaspberryPi_Motor库 下载DFRobot_RaspberryPi_Motor库

进入DFRobot_RaspberryPi_Motor库python所在目录

cd /DFRobot_RaspberryPi_Motor/raspberry

id参数可用使用变量M1,M2,ALL,分别表示电机M1,电机M2,M1和M2

set_encoder_enable(self, id)

例:

board = Board(1,0x10)

set_encoder_enable([board.M1])#使能编码器电机M1

set_encoder_enable([board.M2])#使能编码器电机M2

set_encoder_enable([board.M1,board.M2])#使能编码器电机M1和M2

set_encoder_enable(board.ALL)#使能编码器电机M1和M2

- step2.设置电机减速比(demo默认43:1) 跟电机的减速比有关

set_encoder_reduction_ratio(self, id, reduction_ratio)

- step3.设置PWM信号的频率(demo默认为1000Hz)

set_moter_pwm_frequency(self, frequency)

- step4.指定M1,M2或M1和M2的转向(正转或反转),和速度(占空比0~100)

motor_movement(self, id, orientation, speed)

get_encoder_speed(self, id)

warning_yellow.png warning_yellow.png

|

注:使用不同电机,其减速比参数不同,在运行demo之前,需修改所用电机的减速比! |

更多功能配置及使用方法说明'''

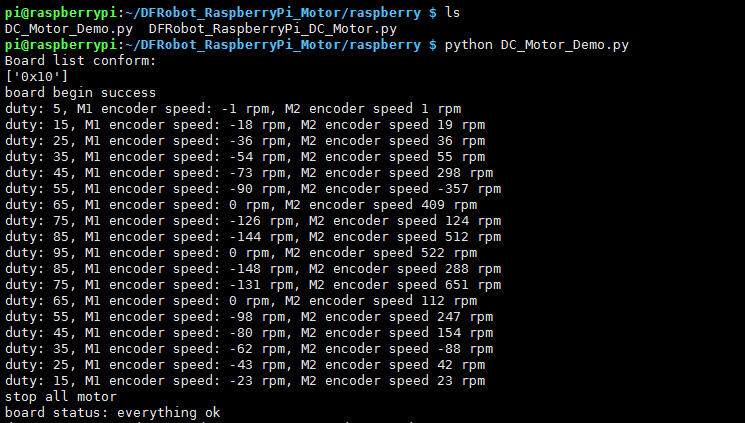

运行DC_Motor_Demo.py示例(所用电机减速比为120:1,已修改为120),打印编码器电机的占空比和转速。

python DC_Motor_Demo.py

程序代码如下所示:

|

# -*- coding:utf-8 -*-

'''

# DC_Motor_Demo.py

#

# Connect board with raspberryPi.

# Make board power and motor connection correct.

# Run this demo.

#

# Motor 1 will move slow to fast, orientation clockwise,

# motor 2 will move fast to slow, orientation count-clockwise,

# then fast to stop. loop in few seconds.

# Motor speed will print on terminal

#

# test motor: https://www.dfrobot.com/product-634.html

#

# Copyright [DFRobot](http://www.dfrobot.com), 2016

# Copyright GNU Lesser General Public License

#

# version V1.0

# date 2019-3-26

'''

import time

from DFRobot_RaspberryPi_DC_Motor import DFRobot_DC_Motor_IIC as Board

board = Board(1, 0x10) # Select bus 1, set address to 0x10

def board_detect():

l = board.detecte()

print("Board list conform:")

print(l)

''' print last operate status, users can use this variable to determine the result of a function call. '''

def print_board_status():

if board.last_operate_status == board.STA_OK:

print("board status: everything ok")

elif board.last_operate_status == board.STA_ERR:

print("board status: unexpected error")

elif board.last_operate_status == board.STA_ERR_DEVICE_NOT_DETECTED:

print("board status: device not detected")

elif board.last_operate_status == board.STA_ERR_PARAMETER:

print("board status: parameter error, last operate no effective")

elif board.last_operate_status == board.STA_ERR_SOFT_VERSION:

print("board status: unsupport board framware version")

if __name__ == "__main__":

board_detect() # If you forget address you had set, use this to detected them, must have class instance

# Set board controler address, use it carefully, reboot module to make it effective

'''

board.set_addr(0x10)

if board.last_operate_status != board.STA_OK:

print("set board address faild")

else:

print("set board address success")

'''

while board.begin() != board.STA_OK: # Board begin and check board status

print_board_status()

print("board begin faild")

time.sleep(2)

print("board begin success")

board.set_encoder_enable(board.ALL) # Set selected DC motor encoder enable

# board.set_encoder_disable(board.ALL) # Set selected DC motor encoder disable

board.set_encoder_reduction_ratio(board.ALL, 120) # Set selected DC motor encoder reduction ratio, test motor reduction ratio is 43.8

board.set_moter_pwm_frequency(1000) # Set DC motor pwm frequency to 1000HZ

while True:

for duty in range(5, 95, 10): # slow to fast

board.motor_movement([board.M1], board.CW, duty) # DC motor 1 movement, orientation clockwise

board.motor_movement([board.M2], board.CCW, duty) # DC motor 2 movement, orientation count-clockwise

time.sleep(1)

speed = board.get_encoder_speed(board.ALL) # Use boadrd.all to get all encoders speed

print("duty: %d, M1 encoder speed: %d rpm, M2 encoder speed %d rpm" %(duty, speed[0], speed[1]))

for duty in range(95, 5, - 10): # fast to low

board.motor_movement([board.M1], board.CW, duty) # DC motor 1 movement, orientation clockwise

board.motor_movement([board.M2], board.CCW, duty) # DC motor 2 movement, orientation count-clockwise

time.sleep(1)

speed = board.get_encoder_speed(board.ALL) # Use boadrd.all to get all encoders speed

print("duty: %d, M1 encoder speed: %d rpm, M2 encoder speed %d rpm" %(duty, speed[0], speed[1]))

print("stop all motor")

board.motor_stop(board.ALL) # stop all DC motor

print_board_status()

time.sleep(4)

|

正面示意图

正面示意图

底面示意图

底面示意图

尺寸图

尺寸图

下载DFRobot_RaspberryPi_Motor库

下载DFRobot_RaspberryPi_Motor库

warning_yellow.png

warning_yellow.png

step3:使能I2C接口。(若已开启可忽略此步)键入命令sudo raspi-config,进入配置界面,操作流程如下所示:

step3:使能I2C接口。(若已开启可忽略此步)键入命令sudo raspi-config,进入配置界面,操作流程如下所示:

配置完成后,键入命令sudo reboot重启树莓派。

step4:检测I2C地址。键入命令i2cdetect -y 1检查设备I2C地址,如下图所示:

配置完成后,键入命令sudo reboot重启树莓派。

step4:检测I2C地址。键入命令i2cdetect -y 1检查设备I2C地址,如下图所示:

step5:下载DFRobot_RaspberryPi_Motor库。键入命令'sudo git clone

step5:下载DFRobot_RaspberryPi_Motor库。键入命令'sudo git clone