URM37_V4.0_Ultrasonic_Sensor_SKU_SEN0001 - jimaobian/DFRobotWiki GitHub Wiki

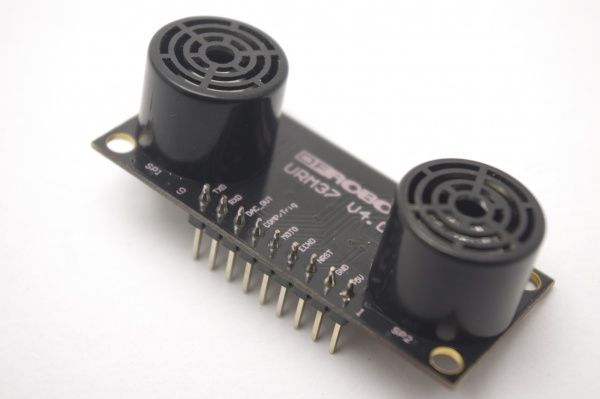

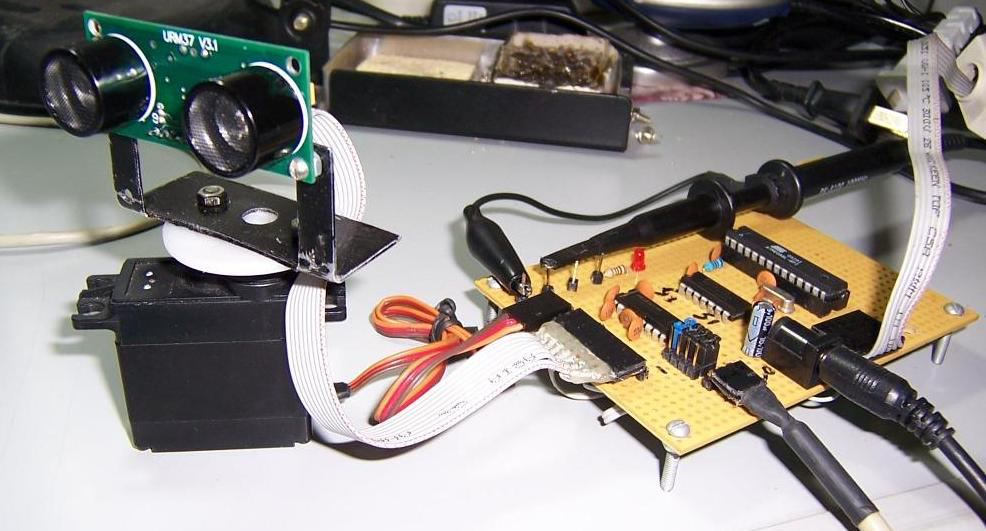

URM37 V4.0 Ultrasonic Sensor uses an industrial level AVR processor as the main processing unit. It comes with a temperature correction which is very unique in its class. URM37 V3.2 (last version) has already been a very good realization of ultrasonic switch and serial (TTL and RS232 level optional), pulse output function, the module can also control a servo rotation to realize a spatial ultrasound scanner. On this basis we have to upgrade the function. URM37 V4.0, the current version has better intelligence capabilities, meanwhile, mechanical dimensions and pin interface and communication commands are compatible with V3.2, V3.2 has been reversed based on the following changes: *Serial level selected from the skipped stitches to button, user can easily select RS232 or TTL-level output level output by pressing the settings( after reboot ).

- Modified the algorithm, so dead zone was reduced and enhance accuracy.

- Analog voltage output, voltage and the measured distance is proportional.

- Wide voltage support +3.3V-5.0V.

- Power reverse protection.

- Automatic measurement of time interval can be modified.

- Modify a servo controlled angle of 0-180, compatible with the most of the servos on the market.

- Measuring time is 100ms.

- Power: +3.3V~+5.0V

- Current: <20mA

- Working temperature: -10℃~+70℃

- Detecting range: 5cm-500cm

- Resolution: 1cm

- Interface: RS232 (TTL), PWM

- Size: 22mm × 51 mm

- Weight: 25g

| style="padding: 5px;" |  |

|---------|-----------|----------------------------------------------------------------------------------------------------------------------------------|

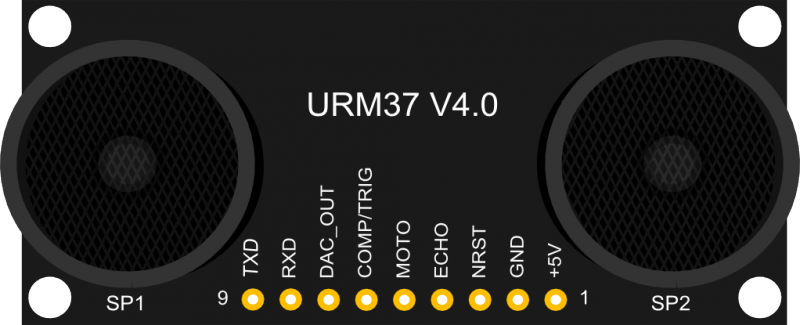

| **Num** | **Label** | **Description** |

| 1 | VCC | Power input (reference +5V) |

| 2 | GND | Ground |

| 3 | NRST | Reset |

| 4 | ECHO | Measured distance presented by the Data Output 0-25000US by PWM pulse width, 1 CM / 50US representative |

| 5 | MOTO | Control the servo rotation angle |

| 6 | COMP/TRIG | COMP:On/OFF mode, when the detecting distance is smaller than a pre-set value, this pin pulls low./TRIG:PWM mode trigger input |

| 7 | DAC | Analog voltage output ( each 6.8mV represents 1 cm ) |

| 8 | RXD | RS232/TTL mode |

| 9 | TXD | RS232/TTL mode | |

Congratulations to you who bought our URM37 V4.0 Ultrasonic Sensor3, you now have the historical most powerful ultrasonic ranging module. First we have to understand this module basic function, there are three modes:

- PWM triggered measurement mode

- Automatically measure mode

- Serial passive measurement

Then it also supports:

- Simulation volume output (proportional with measurement distance, 6.8mV/cm )

- Temperature read

- Serial level choose(TTL or RS232 level)

- Internal EEPROM without losing data

- Serial EEPROM data read

The products have been conducted a set of rigorous tests by us, when you get your purchase, you can do some setting according to your demands, firstly, you may have to set the serial port-level (or RS232 TTL level), then we can access to the module through the serial port, then set the range mode (0x02 writes data on the internal EEPROM address), after that, you can access to ultrasound module through MCU or PC.

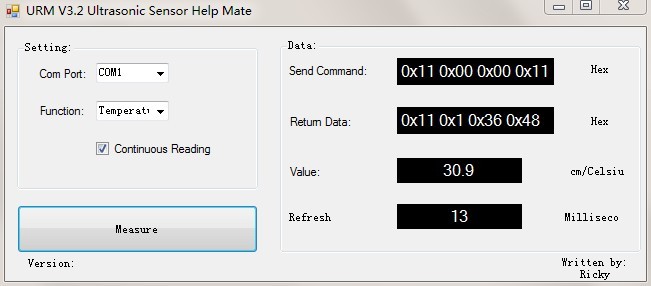

To begin with this Ultrasonic Sensor, there is a software could help to make it a lot of easier.And there are some paramenters you may want to reverse to meet more situations.

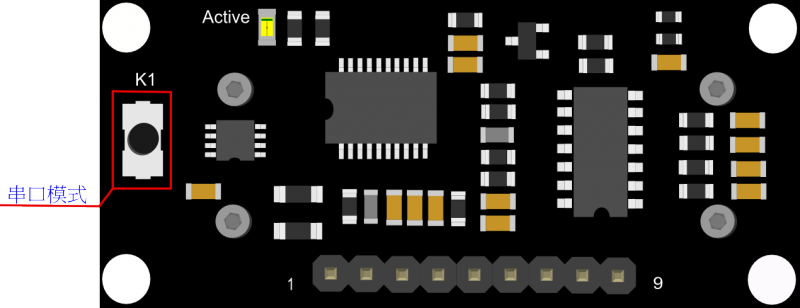

The vesy fisrt basic step to communicate with the model is to choose the serial level_TTL(default) or RS232.We step forward over the last version3.2 which by jumper, now we could do it by pressing the only one button on the board for 1 second, after the light turn off from state-on, release the botton.Repower again,he Indicator appears to flash like once long and once short -present TTL level output, once long and twice short flash presenting RS232 level.

|

Do not connect to TTL MCU when the output mode is set to RS232, doing so will permanently damage the unit. |

This feature is only available for Rev2 and after. If there are no jumpers, or no button on the back of the sensor, the sensor should be Rev1 and hence not supporting this feature.

image:sen0001_ConnectionDiagram.png|TTL Mode Connection Diagram image:URM37232.png|RS232 Mode Connection Diagram

Power on the sensor, read the blink of the LED(active) to get the serial level(see above), wire according to the above picture.After this,you can use our "URMV3.2HelpMate" to test the module.

The usage of the software is very simple: ensure that there is no other software on the computer occupied the serial port, and then run Mate.exe, select the COM Port, and choose the parameter what you want to measure, and choose the "Continuous Reading ". Click "Measure" it will measure the temperature and the distance.

Here, we are talking about the meaning of the data in EEPROM several addresses.(For more details, can be found in the https://www.dfrobot.com/wiki/index.php?title=URM37_V3.2_Ultrasonic_Sensor_(SKU:SEN0001)===Serial_control_protocol Serial control protocol part)

| Address | Meaning |

| 0x00 | larger than set distance |

| 0x01 | less than set distance |

| 0x02 | measure mode(write 0xaa present automatically measure mode, other data except 0xaa present PWM Passive measurement mode ) |

| 0x03 | Serial level mode(TTL/RS232)(write 0x00 present TTL mode, 0x01 present RS232 mode, other data will be modified to 0x00) |

| 0x04 | automatically measure time span(default set is the lowest 25ms, witting format is 8-bit 16 binary, e.g. Write 64 means 100ms) |

- Serial TTL level

- Measure mode: PWM trigger

- Comparison of distance : 0

- Automatically measure interval time:25ms

- Internal EEPROM Data are all 0x00

- the EEPROM address are unavailable: 0x00~0x04, please do not try to modify the data.

In PWM trigger mode, pin COMP/TRIG produces a low level of triggered pulse signal starting distance measurement operation once.

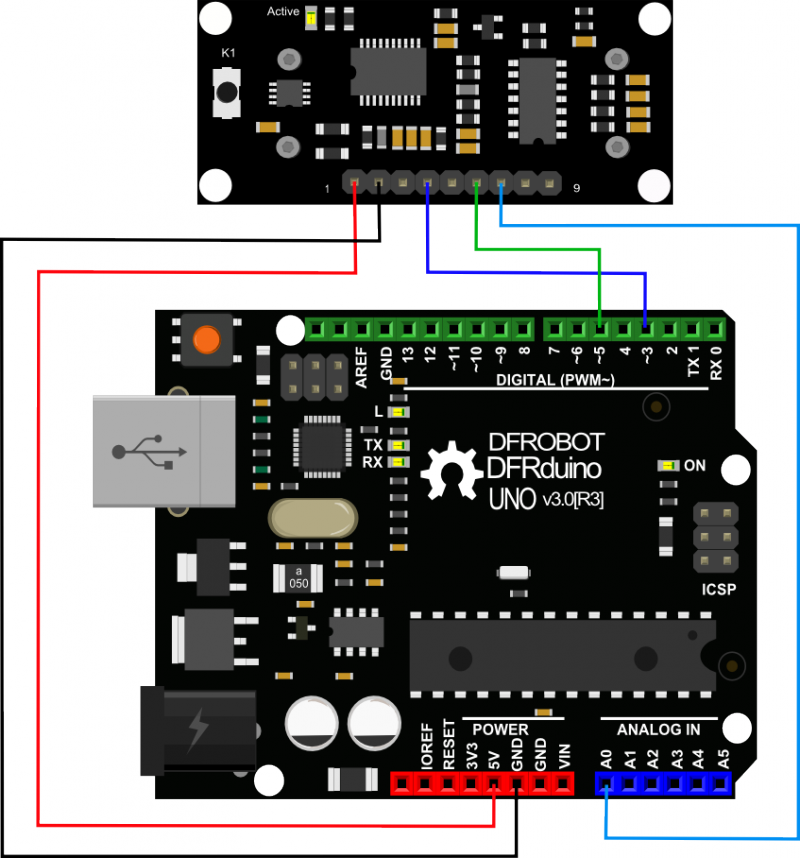

Upload the code below to your arduino board, wire the devices together, then you can realize the distance measurement.

demo code

// # Editor : ZRH from DFRobot

// # Date : 29.08.2014

// # Product name: URM V4.0 ultrasonic sensor

// # Product SKU : SEN0001

// # Version : 1.0

// # Description:

// # The Sketch for scanning 180 degree area 3-500cm detecting range

// # The sketch for using the URM37 PWM trigger pin mode from DFRobot

// # and writes the values to the serialport

// # Connection:

// # Vcc (Arduino) -> Pin 1 VCC (URM V4.0)

// # GND (Arduino) -> Pin 2 GND (URM V4.0)

// # Pin 3 (Arduino) -> Pin 4 ECHO (URM V4.0)

// # Pin 5 (Arduino) -> Pin 6 COMP/TRIG (URM V4.0)

// # Pin A0 (Arduino) -> Pin 7 DAC (URM V4.0)

// # Working Mode: PWM trigger pin mode.

#define Measure 1 //Mode select

int URECHO = 3; // PWM Output 0-25000US,Every 50US represent 1cm

int URTRIG = 5; // PWM trigger pin

int sensorPin = A0; // select the input pin for the potentiometer

int sensorValue = 0; // variable to store the value coming from the sensor

unsigned int DistanceMeasured= 0;

void setup()

{

//Serial initialization

Serial.begin(9600); // Sets the baud rate to 9600

pinMode(URTRIG,OUTPUT); // A low pull on pin COMP/TRIG

digitalWrite(URTRIG,HIGH); // Set to HIGH

pinMode(URECHO, INPUT); // Sending Enable PWM mode command

delay(500);

Serial.println("Init the sensor");

}

void loop()

{

PWM_Mode();

delay(100);

}

void PWM_Mode() // a low pull on pin COMP/TRIG triggering a sensor reading

{

Serial.print("Distance Measured=");

digitalWrite(URTRIG, LOW);

digitalWrite(URTRIG, HIGH); // reading Pin PWM will output pulses

if( Measure)

{

unsigned long LowLevelTime = pulseIn(URECHO, LOW) ;

if(LowLevelTime>=45000) // the reading is invalid.

{

Serial.print("Invalid");

}

else{

DistanceMeasured = LowLevelTime /50; // every 50us low level stands for 1cm

Serial.print(DistanceMeasured);

Serial.println("cm");

}

}

else {

sensorValue = analogRead(sensorPin);

if(sensorValue<=10) // the reading is invalid.

{

Serial.print("Invalid");

}

else {

sensorValue = sensorValue*0.718;

Serial.print(sensorValue);

Serial.println("cm");

}

}

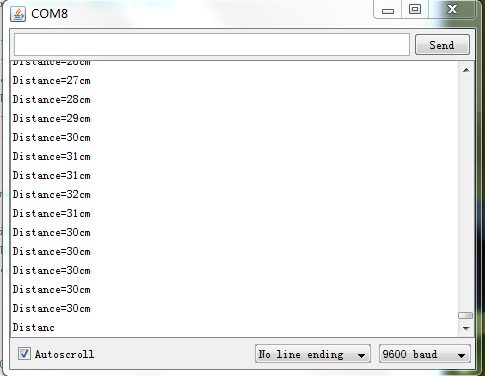

}result

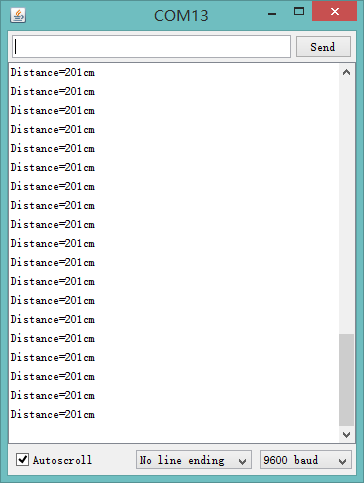

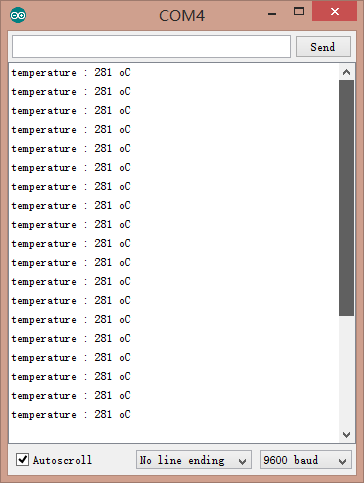

Open the IDE serial port, the distance is display on it.

In the above code, you may not get the distance like 500cm, for we just set it like 450cm.This is just a basic demo, after this, we will dive deeper to find more about it. Note: reverse the code”#define Measure 1 ” to “#define Measure 0”, and it can read the distance by analog value.

| NOTE: PWM trigger mode support multiple parallel modules. |

By means of the computer software or MCU Module, write 0xAA to 0x02 address to switch to automatic measurement mode. Writting a 8-bit 16 binary data to 0x04 address to reverse the measure time interval.

This module measures distance automatically every 25 ms (Settable) , then compare the data with the set value, if equal to or less than the set value, COMP/TRIG pin output low. In addition, in every measure,the PWM Terminal will read the distance as a low level pulse, 50uS represents 1 cm. Tips:if you have set the Compare value, you could use this module as a Ultrasonic Switch.

download the sample code to the arduino board, then wire as shown modules and arduino connected on ultrasonic distance measurement can be achieved.note:download first before connect the Arduino TX/RX, or download will failed.

Demo Code

download the sample code to the arduino board, then wire as shown modules and arduino connected on ultrasonic distance measurement can be achieved.note:download first before connect the Arduino TX/RX, or download will failed.

Demo Code

//Put your code here

// # Editor :Zrh from DFRobot

// # Data :29.08.2014

// # Product name:ultrasonic scanner

// # Product SKU:SEN0001

// # Version : 1.0

// # Description:

// # The sketch for using the URM37 autonomous mode from DFRobot

// # and writes the values to the serialport

// # Connection:

// # Vcc (Arduino) -> Pin 1 VCC (URM V4.0)

// # GND (Arduino) -> Pin 2 GND (URM V4.0)

// # Pin 3 (Arduino) -> Pin 4 ECHO (URM V4.0)

// # Pin TX1 (Arduino) -> Pin 8 RXD (URM V4.0)

// # Pin RX0 (Arduino) -> Pin 9 TXD (URM V4.0)

// # Working Mode: autonomous mode.

int URECHO = 3; // PWM Output 0-25000US,Every 50US represent 1cm

unsigned int Distance=0;

uint8_t EnPwmCmd[4]={0x44,0x02,0xaa,0xf0}; // distance measure command

void setup(){ // Serial initialization

Serial.begin(9600); // Sets the baud rate to 9600

AutonomousMode_Setup();

}

void loop()

{

AutonomousMode();

delay(100);

} //PWM mode setup function

void AutonomousMode_Setup(){

pinMode(URECHO, INPUT); // Sending Enable PWM mode command

for(int i=0;i<4;i++){

Serial.write(EnPwmCmd[i]);

}

}

void AutonomousMode(){

unsigned long DistanceMeasured=pulseIn(URECHO,LOW);

if(DistanceMeasured>=45000){ // the reading is invalid.

Serial.print("Invalid");

}

else{

Distance=DistanceMeasured/50; // every 50us low level stands for 1cm

Serial.print("Distance=");

Serial.print(Distance);

Serial.println("cm");

}

}result

Arduino send the distance information to the computer through serial.

In this mode, actually, as long as you wire the module TX & RX with the MCU, just as we did in the https://www.dfrobot.com/wiki/index.php?title=URM37_V4.0_Ultrasonic_Sensor_(SKU:SEN0001)#2_Test_on_Software test on software,you are using this mode.By serial, you have all authority to access to the sensor such as: ultrasonic distance measurement, temperature measurement, the distance changes, automatic measurement intervals set, serial port set(RS232 or TTL, reboot to take effect). e.g.

- Read the temperature data command: 0x11 0x00 0x00 0x11

- Read the distance data command: 0x22 0x00 0x00 0x22

- Read EEPROM data command: 0x33 0x00 0x00 0x33

- Write EEPROM data command: 0x44 0x02 0x00 0x46

Download the code below to your uno board(if you use the leonardo,please modify the code for the serial problem, help on arduino.cc ), then wire the TX/RX,5V,GND.Follow https://www.dfrobot.com/wiki/index.php?title=URM37_V4.0_Ultrasonic_Sensor_(SKU:SEN0001)#2_Test_on_Software test on software.Here,we use the sensor to read the tempreture. Demo Code

// # Editor : ZRH from DFRobot

// # Date : 29.08.2014

// # Product name: URM V4.0 ultrasonic sensor

// # Product SKU : SEN0001

// # Version : 1.0

// # Description:

// # The sketch for using the URM37 Serial mode from DFRobot

// # and writes the values to the serialport

// # Connection:

// # Vcc (Arduino) -> Pin 1 VCC (URM V4.0)

// # GND (Arduino) -> Pin 2 GND (URM V4.0)

// # Pin TX1 (Arduino) -> Pin 8 RXD (URM V4.0)

// # Pin RX0 (Arduino) -> Pin 9 TXD (URM V4.0)

// # Working Mode: Serial Mode.

uint8_t EnTempCmd[4]={0x11,0x00,0x00,0x11}; // temperature measure command

uint8_t TempData[4];

unsigned int TempValue=0;

void setup()

{

Serial.begin(9600);

delay(100);

Serial.println("Init the sensor");

}

void loop()

{

SerialCmd();

delay(200);

}

void SerialCmd()

{

int i;

for(i = 0;i < 4;i++){

Serial.write(EnTempCmd[i]);

}

while (Serial.available() > 0) //if serial receive any data

{

for(i = 0;i < 4;i++){

TempData[i] = Serial.read();

}

TempValue = TempData[1]<<8;

TempValue =TempValue+TempData[2];

Serial.print("temperature : ");

Serial.print(TempValue,DEC);

Serial.println(" oC");

}

}result

| NOTE: This temperature was magnified 10 times, in the test, actual tempreture is 28.1 degrees Celsius. |

Servo control command reference table:

| DEC | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| HEX | 0 | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 0A | 0B | 0C | 0D | 0E | 0F |

| Degree | 0 | 6 | 12 | 18 | 24 | 29 | 35 | 41 | 47 | 53 | 59 | 65 | 70 | 76 | 82 | 88 |

| DEC | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 |

| HEX | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 1A | 1B | 1C | 1D | 1E | 1F |

| Degree | 94 | 100 | 106 | 112 | 117 | 123 | 129 | 135 | 141 | 147 | 153 | 159 | 164 | 170 | 176 | 182 |

| DEC | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | |

| HEX | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 2A | 2B | 2C | 2D | 2E | |

| Degree | 188 | 194 | 200 | 206 | 211 | 217 | 223 | 229 | 235 | 241 | 247 | 252 | 258 | 264 | 270 |

Arduino Sketch

| NOTE: Please put the sensor jumpers to TTL mode. See above for a picture indicating TTL mode |

// # Editor : Jiang from DFRobot

// # Data : 24.07.2012

// # Product name:ultrasonic scanner Kit

// # Product SKU:SEN0001

// # Version : 0.2

// # Description:

// # The Sketch for scanning 180 degree area 4-500cm detecting range

// # Connection:

// # Pin 1 VCC (URM V3.2) -> VCC (Arduino)

// # Pin 2 GND (URM V3.2) -> GND (Arduino)

// # Pin 4 PWM (URM V3.2) -> Pin 3 (Arduino)

// # Pin 6 COMP/TRIG (URM V3.2) -> Pin 5 (Arduino)

// # Pin mode: PWM

// # Working Mode: PWM passive control mode.

// # If it is your first time to use it,please make sure the two jumpers to the right hand

// # side of the device are set to TTL mode. You'll also find a secondary jumper on

// # the left hand side, you must break this connection or you may damage your device.

#include <Servo.h> // Include Servo library

Servo myservo; // create servo object to control a servo

int pos=0; // variable to store the servo position

int URPWM=3; // PWM Output 0-25000us,every 50us represent 1cm

int URTRIG=5; // PWM trigger pin

boolean up=true; // create a boolean variable

unsigned long time; // create a time variable

unsigned long urmTimer = 0; // timer for managing the sensor reading flash rate

unsigned int Distance=0;

uint8_t EnPwmCmd[4]={0x44,0x22,0xbb,0x01}; // distance measure command

void setup(){ // Serial initialization

Serial.begin(9600); // Sets the baud rate to 9600

myservo.attach(9); // Pin 9 to control servo

PWM_Mode_Setup();

}

void loop(){

if(millis()-time>=20){ // interval 0.02 seconds

time=millis(); // get the current time of programme

if(up){ // judge the condition

if(pos>=0 && pos<=179){

pos=pos+1; // in steps of 1 degree

myservo.write(pos); // tell servo to go to position in variable 'pos'

}

if(pos>179) up= false; // assign the variable again

}

else {

if(pos>=1 && pos<=180){

pos=pos-1;

myservo.write(pos);

}

if(pos<1) up=true;

}

}

if(millis()-urmTimer>50){

urmTimer=millis();

PWM_Mode();

}

}

void PWM_Mode_Setup(){

pinMode(URTRIG,OUTPUT); // A low pull on pin COMP/TRIG

digitalWrite(URTRIG,HIGH); // Set to HIGH

pinMode(URPWM, INPUT); // Sending Enable PWM mode command

for(int i=0;i<4;i++){

Serial.write(EnPwmCmd[i]);

}

}

void PWM_Mode(){ // a low pull on pin COMP/TRIG triggering a sensor reading

digitalWrite(URTRIG, LOW);

digitalWrite(URTRIG, HIGH); // reading Pin PWM will output pulses

unsigned long DistanceMeasured=pulseIn(URPWM,LOW);

if(DistanceMeasured==50000){ // the reading is invalid.

Serial.print("Invalid");

}

else{

Distance=DistanceMeasured/50; // every 50us low level stands for 1cm

}

Serial.print("Distance=");

Serial.print(Distance);

Serial.println("cm");

}

Serial setting:Port rate: 9600; Parity: none; Stop bit: 1

Command: Control command consists of four bits, command+data0+data1+sum. Sum=Low 8 bit of the sum of command+data0+data1.

Command Format |

Function |

Description |

|---|---|---|

0x11+NC+NC+Sum (Sample: 0x11 0x00 0x00 0x11) |

Enable 16 bit temperature reading |

Reading the temperature, the return data format will be: 0x11+High(temperature)+Low(temperature)+SUM |

0x22+Degree+NC+SUM (Sample: 0x22 0x00 0x00 0x22 ) |

Enable 16 bit distance reading |

The degree in the command is used to control a servo motor to rotate corresponding degree. |

0x33+Add+NC+SUM |

Enable internal EEPROM reading |

Return data will be 0x33+Add+Data+SUM. |

0x44+Add+Data+SUM (Sample: 0x44 0x02 0xbb 0x01) Enable PWM mode |

Enable internal EEPROM writing |

Written data can only from 0-255. Address 0x00-0x02 is used to configure the mode. 0x00 – threshold distance (Low) 0x01 – threshold distance (High) 0x02 – Operation Mode (0xaa for autonomous mode) (0xbb for PWM passive control mode) |

| NOTE: NC stands for any data,SUM stands for sum, Add stands for address. |

1. PWN_ON must be set to High to enable sensor.

Examples: Function to calculate the temperature:

IF(HightByte>=0xF0)

{

Temperature= ((HightByte-0xF0)*256-LowByte)/10

}

Else

{

Temperature= ((HightByte)*256-LowByte)/10

}

- If you have connected sensor to the Arduino, but unable to use it, please first check the current serial port-level mode, it may be in TTL level, while our module works in RS232 levels.

- The ultrasonic attenuation violently in the air (inversely proportional to the d²(distance)), besides, barrier surface reflection of the sound is affected by many factors (such as barrier shape, orientation and texture) the influence of ultrasonic distance measurement is therefore limited.

- The far testing distance is a wall, close test can be a pen. Analyte based on the use of the environment and quality of different measurement may result in inconsistent with the data provided.

- The mentioned servo above is a ordinary model on the market, can be rotated 180 degrees. If you use a special steering servo, it may draw the user's attention to control the timing in a different way.

- If you are experiencing technical issues, please ask on our forum or send us email, we will answer your questions as soon as possible. More question and cool idea,visit DFRobot Forum