Romeo_V2 All_in_one_Controller_(R3)_(SKU_DFR0225) - jimaobian/DFRobotWiki GitHub Wiki

Introduction

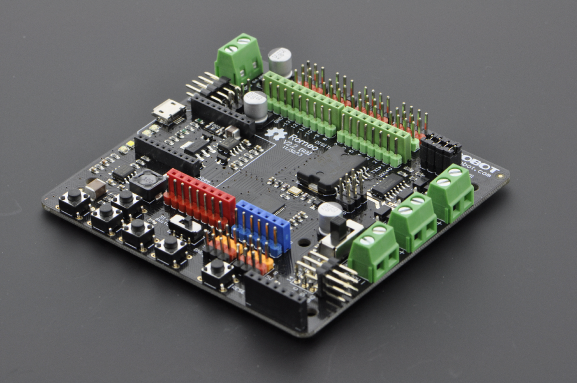

RoMeo V2[R3]is an All-in-One Arduino compatible microcontroller especially designed for robotics applications from DFRobot. The Romeo benefits from the Arduino open source platform, it is supported by thousands of open source codes, and can easily be expanded with Arduino Shields. The integrated 2 way DC motor driver and Xbee socket allows you to start your project immediatly without the need for an additional motor driver or wirless shield.

|style="float:left; margin-left: 10px;"|

|style="float:left; margin-left: 10px;"|

- The analog sensor port pin mapping on RoMeo v2 is different from the version before. Be careful to wire your sensor or other devices correctly or the wrong power connection would destroy your device.

- Please Turn OFF the Motor Power Switch when debugging Romeo through USB cable. Or the external power supply(>12V) will destroy your Romeo.

NOTE:

- Please select Leonardo board when uploading a sketch by Arduino IDE.

- Serial port 0 or 1 Read more from Arduino.cc: Please use Serial1.***() instead of Serial.***() in code to communicate with devices connected to serial interface, i.e. Pin 0/1. e.g. Bluetooth, WiFi module, Xbee etc. Serial.***() is for USB debugging on pc serial monitor.

- Analog 0: If you are going to use the Analog port 0, you have to pay attention to the switch(s1-s5), turn it OFF please. There are five buttons connected to A0, if you turn ON the button switch,then the A0 read value would be not the one you want.

Specification

| '''Basic ''' | Feature | Improvement compared with Romeo v1.1 |

| - DC Supply:USB Powered or External 6V~23V DC |

- DC Output:5V(200mA) / 3.3V(100mA)

- Motor driver Continuous Output Current:2A

- Microcontroller:ATmega32u4

- Bootloader: Arduino Leonardo

- Serial Interface - TTL Level(Serial1.***();)

- USB(Serial.***())

- Size:89x84x14mm | - Compatible with the Arduino R3 pin mapping - Analog Inputs: A0-A5, A6 - A11 (on digital pins 4, 6, 8, 9, 10, and 12) - PWM: 3, 5, 6, 9, 10, 11, and 13. Provide 8-bit PWM output - 5 key inputs for testing - Auto sensing/switching external power input - Support Male and Female Pin Header - Built-in Xbee socket - Integrated sockets for APC220 RF Module and DF-Bluetooth Module - Three I2C/TWI Interface Pin Sets(two 90°pin headers) - Two way Motor Driver with 2A maximum current | - Wide operating input voltage - Directly support Xbee and XBee form factor wifi,bluetooth and RF modules - ON/OFF switch to control the system power from extermal motor power - 3 Digital I/O extension(D14-D16) - S1-S5 switch replace jump cap - Micro USB instead of A-B USB connector - Analog sensor extension port: Orange for Signal,Red for Vcc,Black for GND |

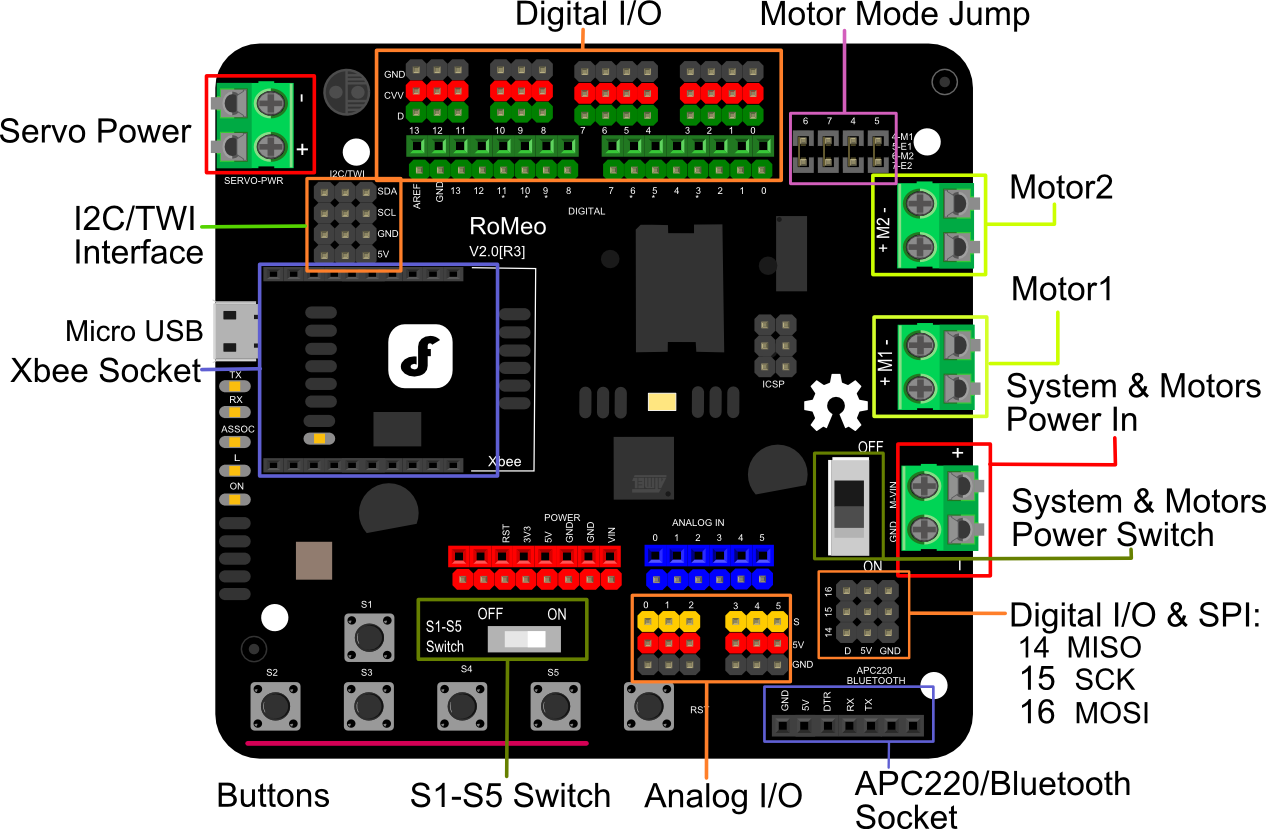

RoMeo V2 Pinout

Power solution design

This motor controller power solution is specially designed for the robotics application. Servo Power terminal

- It integrated an external servo power terminal. The range of this power input is about 5

12v. We recommend you to use 5v. So the servo power supply extension won't break the digital sensors connected to the 3p digital sensor interface. However,for driving 612v servos with the voltage input higher than 5v, it's not available to extend 5v sensor on all the digital sensor interface anymore. - The servo power terminal won't supply system working voltage.

Motor Power terminal The setting for the system & motor power switch:

- On: supply power to the motor driver and system power regulator. The input range is from 5~23 volts. It's suitable for most of robot platform.

- Off: Isolate the system power supply from the motor power. In this case, it requires to supply system voltage from Micro USB port,5v power source to 5v & GND pins directly or 5~23v power source to VIN & GND pins.

Example use of Button S1-S5

char msgs[5][15] = {

"Right Key OK ",

"Up Key OK ",

"Down Key OK ",

"Left Key OK ",

"Select Key OK" };

char start_msg[15] = {

"Start loop "};

int adc_key_val[5] ={

30, 150, 360, 535, 760 };

int NUM_KEYS = 5;

int adc_key_in;

int key=-1;

int oldkey=-1;

void setup() {

pinMode(13, OUTPUT); //we'll use the debug LED to output a heartbeat

Serial.begin(9600);

/* Print that we made it here */

Serial.println(start_msg);

}

void loop()

{

adc_key_in = analogRead(0); // read the value from the sensor

digitalWrite(13, HIGH);

/* get the key */

key = get_key(adc_key_in); // convert into key press

if (key != oldkey) { // if keypress is detected

delay(50); // wait for debounce time

adc_key_in = analogRead(0); // read the value from the sensor

key = get_key(adc_key_in); // convert into key press

if (key != oldkey) {

oldkey = key;

if (key >=0){

Serial.println(adc_key_in, DEC);

Serial.println(msgs[key]);

}

}

}

digitalWrite(13, LOW);

}

// Convert ADC value to key number

int get_key(unsigned int input)

{

int k;

for (k = 0; k < NUM_KEYS; k++)

{

if (input < adc_key_val[k])

{

return k;

}

}

if (k >= NUM_KEYS)

k = -1; // No valid key pressed

return k;

}

Pin Allocation

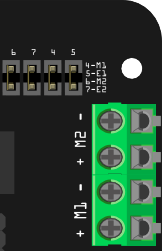

*PWM Mode

| Pin | Function |

|---|---|

| Digital 4 | Motor 1 Direction control |

| Digital 5 | Motor 1 PWM control |

| Digital 6 | Motor 2 PWM control |

| Digital 7 | Motor 2 Direction control |

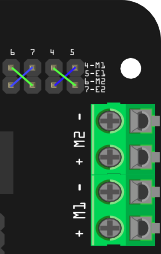

- PLL Mode

| Pin | Function |

|---|---|

| Digital 4 | Motor 1 Enable control |

| Digital 5 | Motor 1 Direction control |

| Digital 6 | Motor 2 Direction control |

| Digital 7 | Motor 2 Enable control |

PWM Control Mode

the pwm dc motor control is implemented by manipulating two digital io pins and two pwm pins. as illustrated in the diagram above (Figure 5), Pin 4,7 (7,8 for old Romeo version) are motor direction control pins, Pin 5,6 (6,9 for old Romeo version) are motor speed control pins.

the pwm dc motor control is implemented by manipulating two digital io pins and two pwm pins. as illustrated in the diagram above (Figure 5), Pin 4,7 (7,8 for old Romeo version) are motor direction control pins, Pin 5,6 (6,9 for old Romeo version) are motor speed control pins.

Sample Code:

//Standard PWM DC control

int E1 = 5; //M1 Speed Control

int E2 = 6; //M2 Speed Control

int M1 = 4; //M1 Direction Control

int M2 = 7; //M1 Direction Control

///For previous Romeo, please use these pins.

//int E1 = 6; //M1 Speed Control

//int E2 = 9; //M2 Speed Control

//int M1 = 7; //M1 Direction Control

//int M2 = 8; //M1 Direction Control

void stop(void) //Stop

{

digitalWrite(E1,LOW);

digitalWrite(E2,LOW);

}

void advance(char a,char b) //Move forward

{

analogWrite (E1,a); //PWM Speed Control

digitalWrite(M1,HIGH);

analogWrite (E2,b);

digitalWrite(M2,HIGH);

}

void back_off (char a,char b) //Move backward

{

analogWrite (E1,a);

digitalWrite(M1,LOW);

analogWrite (E2,b);

digitalWrite(M2,LOW);

}

void turn_L (char a,char b) //Turn Left

{

analogWrite (E1,a);

digitalWrite(M1,LOW);

analogWrite (E2,b);

digitalWrite(M2,HIGH);

}

void turn_R (char a,char b) //Turn Right

{

analogWrite (E1,a);

digitalWrite(M1,HIGH);

analogWrite (E2,b);

digitalWrite(M2,LOW);

}

void setup(void)

{

int i;

for(i=4;i<=7;i++)

pinMode(i, OUTPUT);

Serial.begin(19200); //Set Baud Rate

Serial.println("Run keyboard control");

}

void loop(void)

{

if(Serial.available()){

char val = Serial.read();

if(val != -1)

{

switch(val)

{

case 'w'://Move Forward

advance (255,255); //move forward in max speed

break;

case 's'://Move Backward

back_off (255,255); //move back in max speed

break;

case 'a'://Turn Left

turn_L (100,100);

break;

case 'd'://Turn Right

turn_R (100,100);

break;

case 'z':

Serial.println("Hello");

break;

case 'x':

stop();

break;

}

}

else stop();

}

}

PLL Control Mode

The Romeo also supports PLLPhase locked loop control mode.

Sample Code:

//Standard DLL Speed control

int E1 = 4; //M1 Speed Control

int E2 = 7; //M2 Speed Control

int M1 = 5; //M1 Direction Control

int M2 = 6; //M1 Direction Control

///For previous Romeo, please use these pins.

//int E1 = 6; //M1 Speed Control

//int E2 = 9; //M2 Speed Control

//int M1 = 7; //M1 Direction Control

//int M2 = 8; //M1 Direction Control

//When m1p/m2p is 127, it stops the motor

//when m1p/m2p is 255, it gives the maximum speed for one direction

//When m1p/m2p is 0, it gives the maximum speed for reverse direction

void DriveMotorP(byte m1p, byte m2p)//Drive Motor Power Mode

{

digitalWrite(E1, HIGH);

analogWrite(M1, (m1p));

digitalWrite(E2, HIGH);

analogWrite(M2, (m2p));

}

void setup(void)

{

int i;

for(i=6;i<=9;i++)

pinMode(i, OUTPUT);

Serial.begin(19200); //Set Baud Rate

}

void loop(void)

{

if(Serial.available()){

char val = Serial.read();

if(val!=-1)

{

switch(val)

{

case 'w'://Move Forward

DriveMotorP(0xff,0xff); // Max speed

break;

case 'x'://Move Backward

DriveMotorP(0x00,0x00);

; // Max speed

break;

case 's'://Stop

DriveMotorP(0x7f,0x7f);

break;

}

}

}

}

Trouble shooting

More question and cool idea, visit DFRobot Forum

More

buy from dfrobot store or dfrobot distributor list

category: Product Manual category: DFR Series category: Motor Controllers category: MicroControllers category: source

buy from dfrobot store or dfrobot distributor list

category: Product Manual category: DFR Series category: Motor Controllers category: MicroControllers category: source