Cratering in Aluminum 1100 - isale-code/isale-wiki GitHub Wiki

This is an impact of a 6.35-mm diameter aluminium sphere into an aluminium target. The impact velocity is 7km/s. The impactor is represented by the Tillotson equation of state for Aluminium. Gravity is not considered in this calculation. No geotherm is set in the test case---the target has a constant temperature of 293K.

The model is an attempt to reproduce the aluminium validation experiments of Pierazzo et al. (2008). There are two validation tests to run into different alloys of Aluminium. This example uses Al alloy 1100-O (see also the other aluminium example using alloy aluminum 6061).

Go to the relevant example directory

cd /share/examples/aluminum_1100_2D

Run iSALE2D. The simulation will take several minutes, so this should be run in the background.

./iSALE2D &

Now, perform some postprocessing. To do this with pySALEPlot:

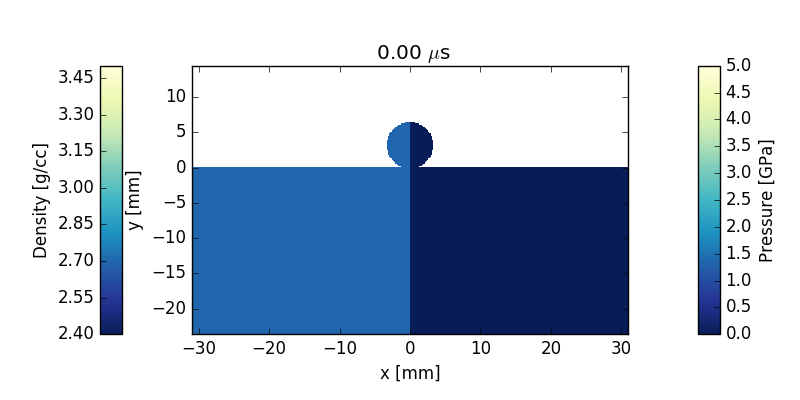

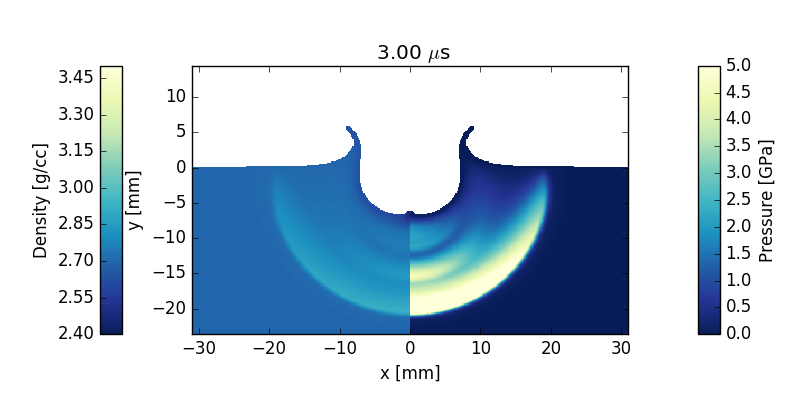

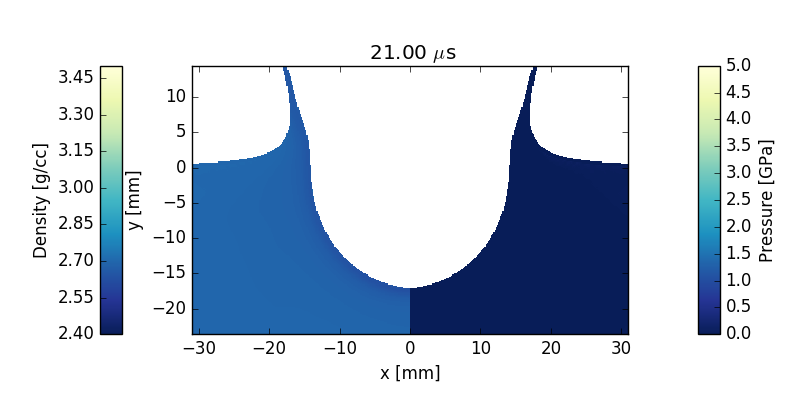

python Plotting/DenPre.py

The images, which should be identical to those shown below, will be output to the directory DenPre/. The pySALEPlot plotting script can easily be modified to generate additional images and analysis.

We can also use pySALEPlot to measure the crater dimensions as a function of time (using the model.craterGrowth() pySALEPlot function).

python Plotting/cratergrowth.py

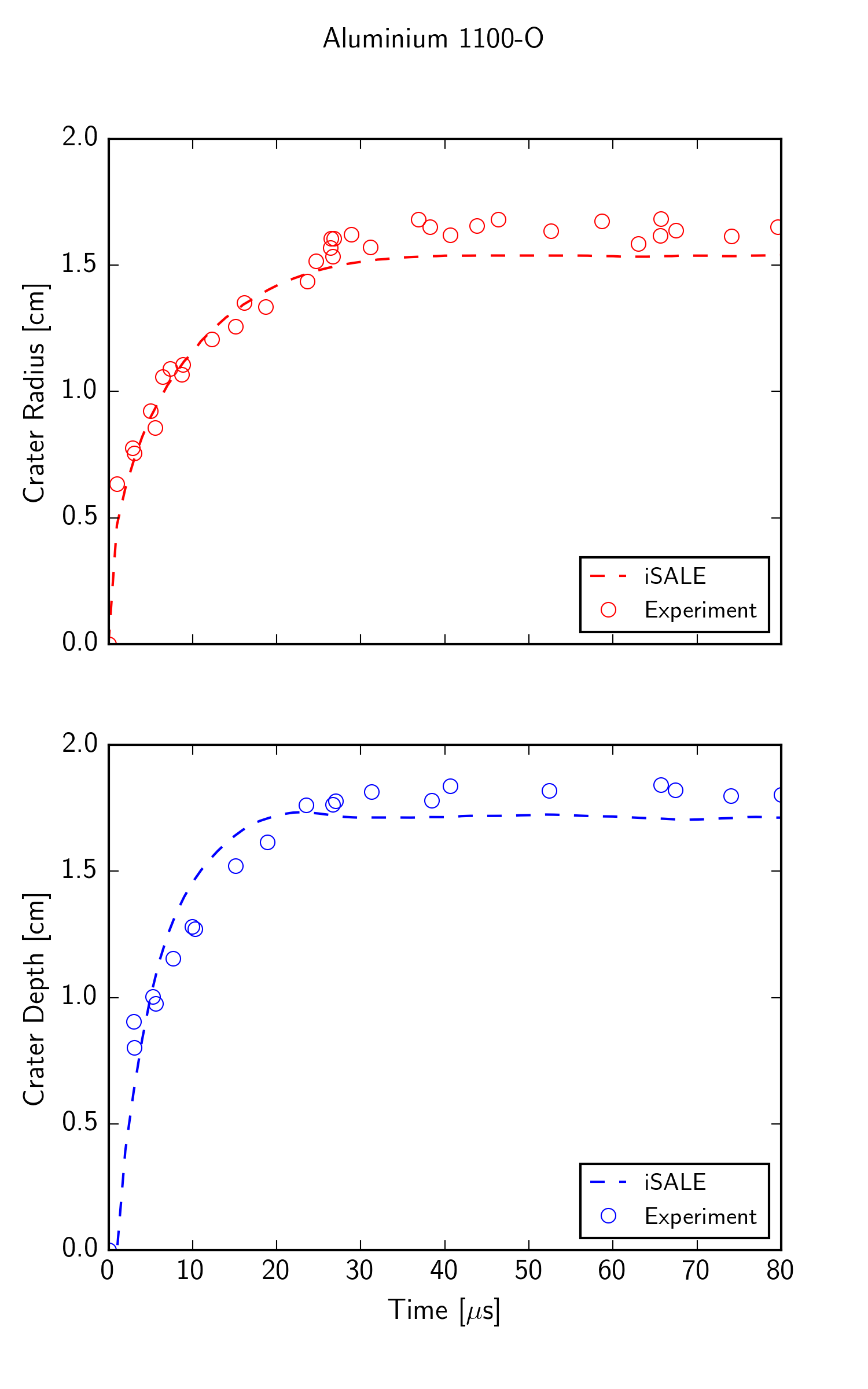

This will output a figure (cratergrowth.png) which plots the iSALE crater dimensions against the experiments documented in Pierazzo et al. (2008).

To use pySALEPlot to compare this model with the aluminum 6061 example, see psp_plot_multiple_models

Model parameters for simulation.

| DESCRIPTION | VALUE |

|---|---|

| Number of high-resolution cells in x-direction | 200 |

| Number of high-resolution cells in y-direction | 240 |

| Cell size in x-direction (m) | 0.15875 |

| Cell size in y-direction (m) | 0.15875 |

| Surface temperature (deg. Kelvin) | 293 |

| Gravitational acceleration (m/s2) | 0.00 |

| Projectile diameter (mm) | 6.35 |

| Projectile velocity (km/s) | 7. |

| Projectile material (number) | al-1100 |

Target layers for simulation.

| MATERIAL LAYER | THICKNESS (mm) |

|---|---|

| aluminu | 23.8 |

Model material parameters.

| DESCRIPTION | VALUE |

|---|---|

| Poisson ratio | 0.33 |

| JC strain coefficient A (MPa) | 49 |

| JC strain coefficient B (MPa) | 157 |

| JC strain exponent | 0.167 |

| JC strain rate coefficient | 0.016 |

| JC thermal softening | 1.7 |

| JC reference temperature (K) | 293 |

| Melt temperature (K) | 933 |

| Specific heat capacity (J/kg/K) | 896 |

Simulation setup is written in asteroid.inp:

------------------- General Model Info ---------------------------------

VERSION __DO NOT MODIFY__ : 4.1

DIMENSION dimension of input file : 2

PATH Data file path : ./

MODEL Modelname : aluminium_1100_2D

------------------- Mesh Geometry Parameters ---------------------------

GRIDH horizontal cells : 0 : 200 : 50

GRIDV vertical cells : 50 : 240 : 0

GRIDEXT ext. factor : 1.05d0

GRIDSPC grid spacing : 1.5875D-4

CYL Cylind. geometry : 1.0D0

GRIDSPCM max. grid spacing : 3.D-3

------------------- Global setup parameters -----------------------------

S_TYPE setup type : DEFAULT

GRAD_TYPE gradient type : NONE

T_SURF Surface temp : 293.D0

------------------- Projectile ("Object") Parameters --------------------

OBJNUM number of objects : 1

OBJRESH CPPR horizontal : 20

OBJVEL object velocity : -7.D3

OBJMAT object material : al-1100

OBJTYPE object type : SPHEROID

------------------- Target Parameters ----------------------------------

LAYNUM layers number : 1

LAYPOS layer position : 200

LAYMAT layer material : al-1100

------------------- Time Parameters ------------------------------------

DT initial time increment : 3.175D-8

DTMAX maximum timestep : 5.D-3

TEND end time : 8.01D-5

DTSAVE save interval : 1.D-6

------------------- Boundary Condition Parameters ----------------------

BND_L left : FREESLIP

BND_R right : FREESLIP

BND_B bottom : NOSLIP

BND_T top : OUTFLOW

------------------- Numerical Stability Parameters ---------------------

AVIS art. visc. linear : 0.2D0

AVIS2 art. visc. quad. : 1.0D0

------------------- Tracer Particle Parameters -------------------------

TR_QUAL integration qual. : 1

TR_SPCH tracer spacing X : 1.5875D-4 : 1.5875D-4

TR_SPCV tracer spacing Y : 1.5875D-4 : 1.5875D-4

TR_VAR add. tracer fiels : #TrP-TrT#

------------------- (Material) Model parameters (global) ---------------

STRESS Consider stress : 1

PARTPRES Pres. in part. : 1

------------------- Data Saving Parameters -----------------------------

QUALITY Compression rate : -50

VARLIST List of variables : #Den-Tmp-Pre-Sie-Yld-VEL#

------------------------------------------------------------------------

Material parameters used in the model are written in material.inp:

-------------------------------------------------------- MATNAME Material name : al-1100 EOSNAME EOS name : aluminu EOSTYPE EOS type : tillo STRMOD Strength model : JNCK DAMMOD Damage model : NONE ACFL Acoustic fluidisation : NONE PORMOD Porosity model : NONE THSOFT Thermal softening : JNCK LDWEAK Low density weakening : NONE ----- Elastic strength parameters ---------------------- POIS pois : 3.3000D-01 ----- Minimum Pressure --------------------------------- PMININ minimum pressure : -2.440D+09 ----- Thermal parameters ------------------------------- TMELT0 tmelt0 : 9.3300D+02 ASIMON a_simon : 6.0000D+09 CSIMON c_simon : 3.0000D+00 ----- Johnson-Cook strength parameters ----------------- JC_A strain coeff. a : 4.9000D+07 JC_B strain coeff. b : 1.5700D+08 JC_N strain exponent : 1.6700D-01 JC_C str. rate coeff c : 1.6000D-02 JC_M thermal soft. : 1.7000D+00 JC_TREF ref. temperature : 2.9300D+02 --------------------------------------------------------

The figure below shows a comparison of iSALE model data with the experimental results from Pierazzo et al. (2008).

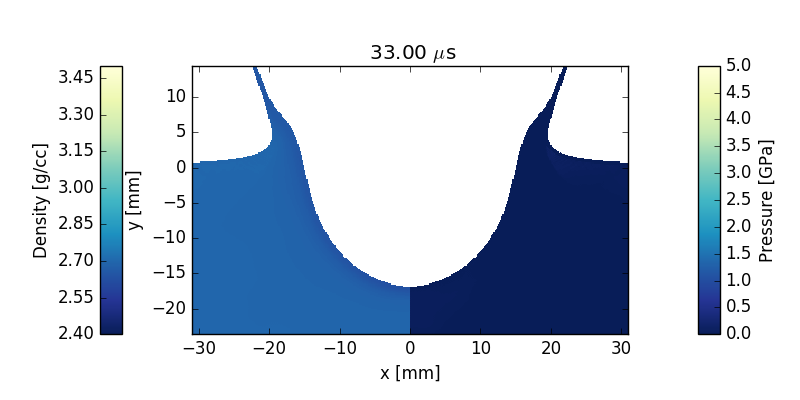

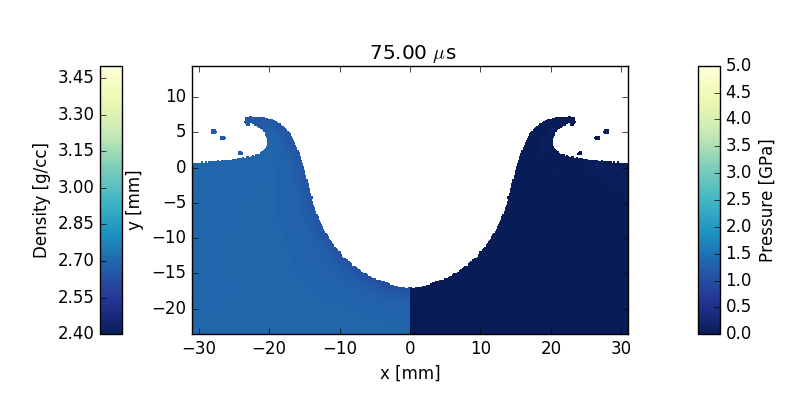

The following figures show several timesteps showing the growth of the crater in Al 1100-O.

Pierazzo E., Artemieva N., Asphaug E., Baldwin E.C., Cazamias J., Coker R., Collins G.S., Crawford D.A., Davison T.M., Elbeshausen D., Holsapple K.A., Housen K.R., Korycansky D G, and Wünnemann K. (2008). Validation of numerical codes for impact and explosion cratering: Impacts on strengthless and metal targets. Meteoritics and Planetary Science 43:1917-1938.