Virtual implementation - h-division-2018-2019-even/Repo-9 GitHub Wiki

SUBSYSTEM-1:MOVEMENT AND DIGGING

3-D MODEL

BILL OF MATERIALS (BOM)

| Sl. No | Part Name | Material with which the part is made up of | Description about part | Quantity required | Fabrication process if needed |

|---|---|---|---|---|---|

| 1 | Micro controller | - | Arduino mega AT2560 | 1 | - |

| 2 | DC geared Motor | - | 30 rpm | 4 | - |

| 3 | Blades | Steel | High tensile strength and 10 cm long,3 cm wide, 1 cm thick | 5 | Digging |

| 4 | Wheels | Polycarbonate Plastic | Strong Thermpolastic 5 cm | 4 | - |

| 5 | Base | Steel sheet | 40 cm length, 30 cm breadth, 5 cm height | 1 | - |

| 6 | Clamp | Steel sheet | - | 4 | Hold DC Motor |

| 7 | Nuts and Bolts | Steel | - | 10 | - |

FLOW CHART

CIRCUIT DIAGRAM

SUBSYSTEM-2:SOWING AND STORAGE

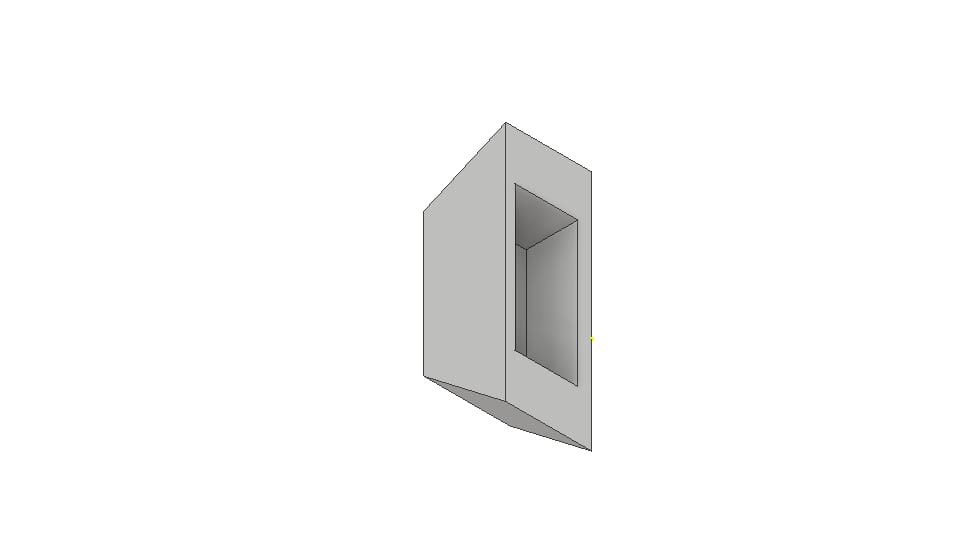

3D Model

BILL OF MATERIALS (BOM)

| Sl. No | Part Name | Material with which the part is made up of | Description about part | Quantity required | Fabrication process if needed |

|---|---|---|---|---|---|

| 1 | Stepper Motor | - | 28BYJ48 | 2 | - |

| 2 | Stepper Motor Driver | - | ULN2003 | 2 | - |

| 3 | Jumper Wires | Male to Female and Female to Female | 20 | - | |

| 4 | Breadboard | White plastic | 440 points | 1 | - |

| 5 | Wifi module | - | ESP8266 | 1 | - |

| 6 | Container | Acrylic sheet | Optical clarity,strong and tough | 1 | Cutting and bending |

| 7 | Seed drop Wheels | - | - | 5 | - |

| 8 | Relay | - | 2 channel relay | 1 | - |

| 9 | Nuts and Bolts | Steel | - | 10 | - |

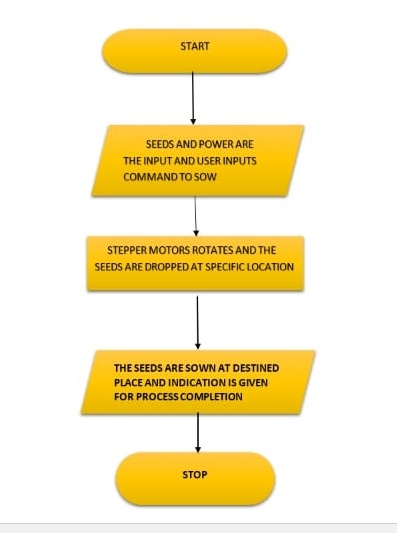

FLOW CHART

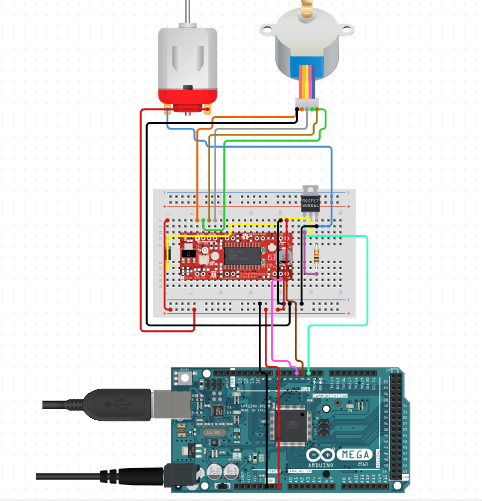

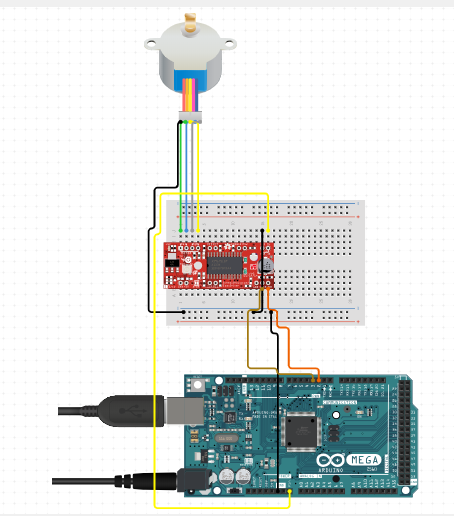

CIRCUIT DIAGRAM

SUBSYSTEM-3:OBSTACLE DETECTION,COVERING,NOTIFICATION

BILL OF MATERIALS (BOM)

| Sl. No | Part Name | Material with which the part is made up of | Description about part | Quantity required | Fabrication process if needed |

|---|---|---|---|---|---|

| 1 | Covering | Steel sheet | 30 cm wide, 1 cm thick, 10 cm long | 1 | - |

| 2 | Ultrasonic sensor | - | for obstacle detection | 1 | To sense the obstacle if present |

| 3 | IR Sensor | - | 5 V, 20 mA | 1 | To indicate if the container is empty |

| 4 | LED | Glass | - | 5 | For indication |

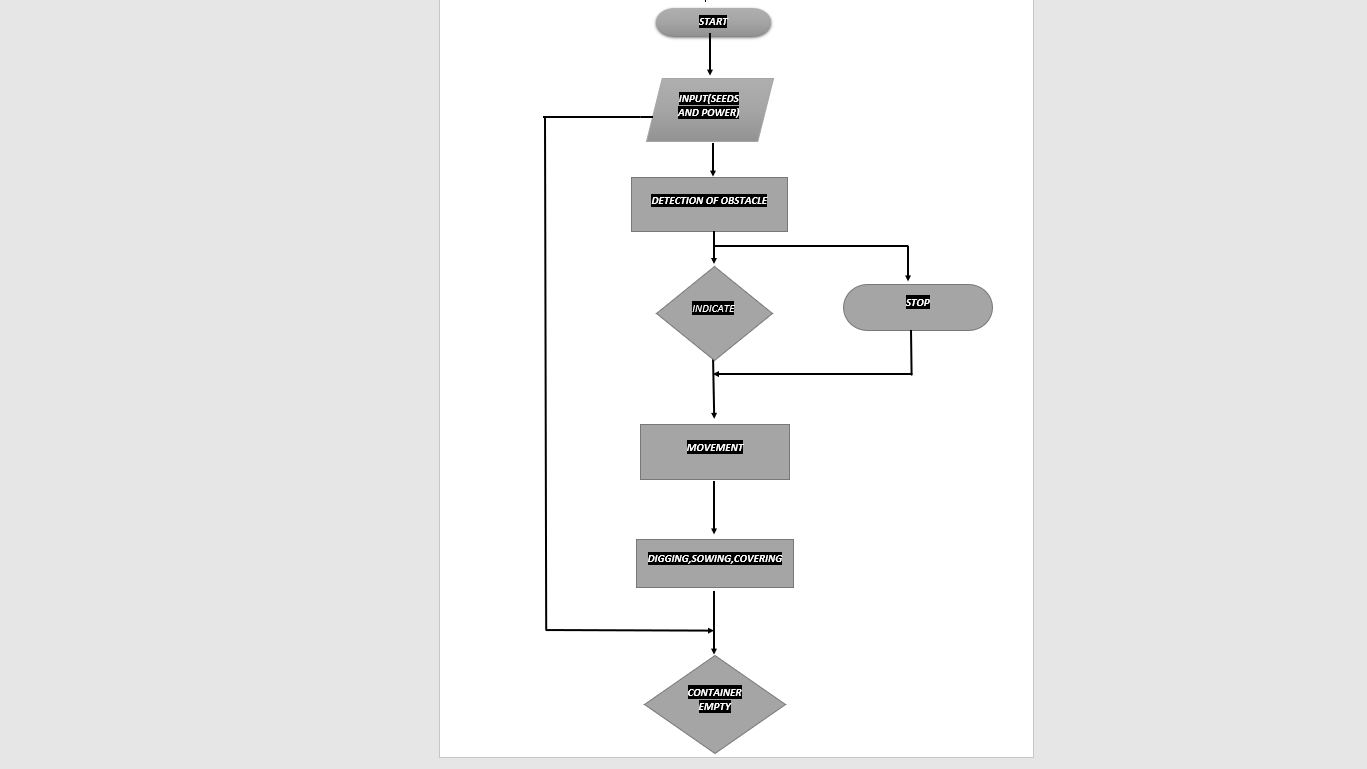

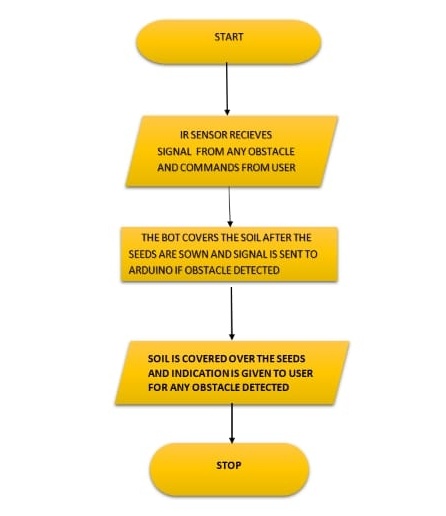

FLOW CHART

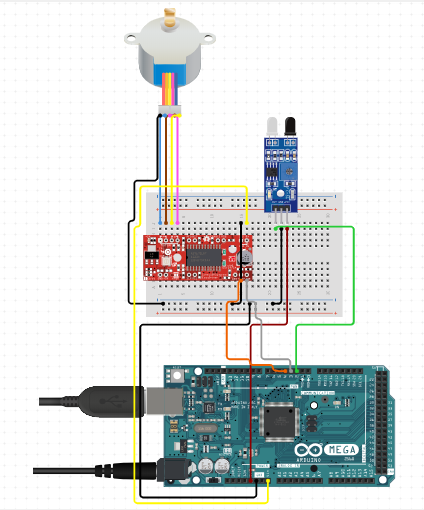

CIRCUIT DIAGRAM

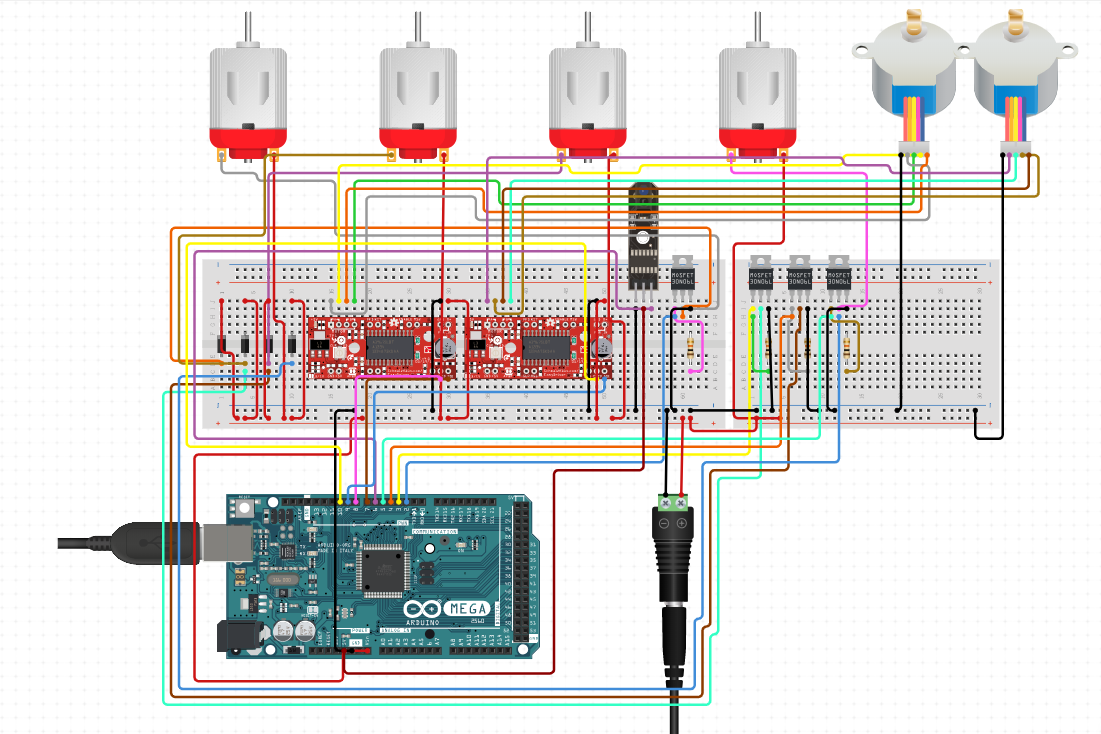

CIRCUIT DIAGRAM OF ENTIRE SYSTEM

FLOW CHART OF THE ENTIRE SYSTEM