materials and supplies.html - frc971/website GitHub Wiki

- FRC 2009 FRC ControlSystem - has all the documents we used to understand and use the 2009 kit of parts including the CRIO programming.

- FRC 2009 FRC ControlSystem - has all the documents we used to understand and use the 2009 kit of parts including the CRIO programming.

- A ChielfDelphi thread recommends the DarkSoul chain breaker for 25 chain. 11/29/09. About $35 each from one vendor. Purchased by Michael 11/29/09 from Dave's Discount Motors for $28.50 + $7 shipping for total of $35.50. http://www.team221.com/viewproduct.php?id=70 lists it for $27.50.

- Purchase gears from AndyMark. They all have 14.5 degree pressure angle. Mixing pressure angles will destroy the gears.

- Pop Rivets for drive wheels. Aluminum Blind Rivet with Aluminum Mandrel Domed, 1/8" Dia, .251"-.312" Material Thickness

- Zip Ties/Cable Ties are available from McMaster-Carr. We don't know if they are the best vendor for these or not. We prefer the black ones. The "Standard" ones are fine. We don't know what lengths would be best to get. It would be nice to have some that fit around the battery connector in one shot. It would be nice to have some long ones that we can use to tie things down without connecting multiple zip ties together.

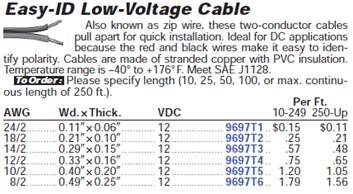

- The motors use 10 Gage wire. The Poofs use zip wire from McMaster-Carr. As of 11/29/09 it is listed on page 790 for $1.20/ft. This compares with $0.50 for a single strand of 10 gauge wire. The premium is $0.20/ft for it to stay together and be flexible. We purchased 50 ft of 9697T5 for the swerve project and used most of it by the end of the first 2010 robot.

-

2010 Rule 47 from Section 8 - The Robot_RevJ

- <R47> All active Power Distribution Board branch circuits shall be wired with appropriately sized wire:

A. 12 AWG (2.052mm) or larger diameter wire must be used for all circuits protected by a 40A circuit breaker. (We use 10 AWG for these circuits. Michael and Austin 50 ft Feb 2010)

B. 14 AWG (1.628mm) or larger diameter wire must be used for all circuits protected by a 30A circuit breaker.

C. 18 AWG (1.024mm) or larger diameter wire must be used for all circuits protected by a 20A circuit breaker. (We will use 18 AWG for the CRIO and all other power electronics in 100 ft Feb 2010. Michael and Austin)

D. 20 AWG (0.8128mm) or larger diameter wire must be used for the power connection between the Power Distribution Board and the cRIO-FRC .

E. 20 AWG (0.8128mm) or larger diameter wire must be used for the power connection between the Power Distribution Board and the Linksys Wireless Bridge

F. 20 AWG (0.8128mm) or larger diameter wire must be used for the power connections between the Power Distribution Board and the Analog Breakouts and/or Solenoid Breakout if individual power feeds are used. 18 AWG or larger diameter wire must be used if a common power feed is used for multiple breakouts.

G. 24 AWG (0.5106mm) or larger diameter wire must be used for providing power to pneumatic valves. (Buy 24 AWG for pneumatic valves. Michael and Austin 100 ft Feb 2010.)

- <R47> All active Power Distribution Board branch circuits shall be wired with appropriately sized wire:

-

Electrical crimp connectors with flanged open ends for are available from McMaster-Carr. The Poofs buy the non insulated connectors and put heat shrink tubing on them. Vinyl ones are fine.

Electrical crimp connectors with flanged open ends for are available from McMaster-Carr. The Poofs buy the non insulated connectors and put heat shrink tubing on them. Vinyl ones are fine.- Part number 7869K67 for 10 AWG to #6 screws for victors. $16 for a box of 100.Search McMaster-Carr for the part number.

- 14-16 AWG for lower amp motors. $12 for box of 100. 7869K64

- 22-18 AWG for fans on victors. $11 for box of 100. 7869K61

-

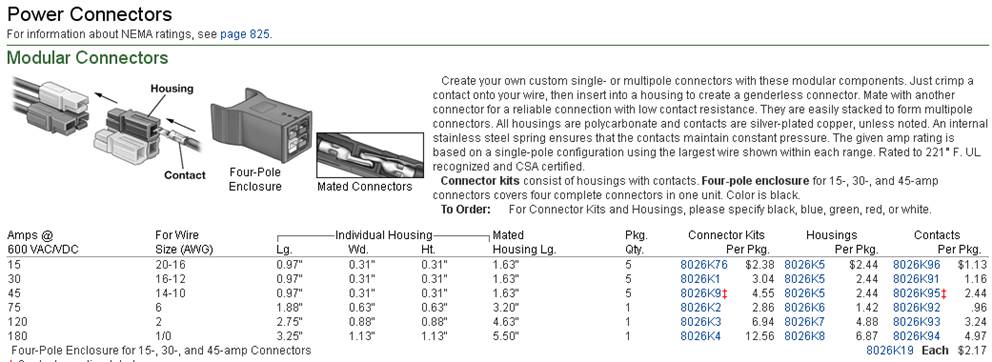

The Poofs use Modular Connectors from McMaster-Carr page 764 as of 11/29/09 for connecting the robot superstructure to the base. They use the 15 amp, 30 amp, and 45 amp connectors. If not assembled perfectly, they come apart or have a poor connection (Travis Covington). Use these with caution. Austin thinks these are the same ones that Roy uses.

- PWM kit came from Hansen Hobbies

- HH-CK_DRCCK1_UN+WST $98 Deluxe RC Connector Kit (Version I) with Universal Connectors + Wire Stripping Tool, Sept 23, 2009 Michael Schuh

-

Purchased 2/27/10 by Michael, Austin, Parker, Wyn, and Jerry. $162.21 with $4.95 shipping and no tax.Universal/JR Servo Connector Housings (x100)

Item #: HH-SC_UNH (x100)$24.43 USD 2 $48.86 USD Economy 24AWG Servo Wire - 100ft

Item #: HH-SW_EC24 (100ft)$23.95 USD 1 $23.95 USD Wire Stripper 10-22AWG

Item #: HH-STRIP_10-22AWG$9.95 USD 2 $19.90 USD Wire Stripper 14-24AWG

Item #: HH-STRIP_14-24AWG$9.95 USD 1 $9.95 USD .1in Female Gold Terminals (x300)

Item #: HH-PT1IN_FT (x300)$18.20 USD 2 $36.40 USD .1in Male Gold Terminals (x300)

Item #: HH-PT1IN_MT (x300)$18.20 USD 1 $18.20 USD

We use an old Di-Acro 24" press brake we bought used to bend sheet metal parts. The K-Factor is used by SolidWorks to generate flat parts that have been adjusted so that they bend up to the correct size. The K-Factors below were determined using bend radii of 1/2 the material thicknesses. The "Magic Flange Length" is the length of a flange that results from a part placed in the press brake with the edge of the part flush with the face of the die. For the 1/8" Lexan, the magic bend length is for the back stop pushed up against the back of the acuate angle die. These bends are quick and easy to make very accurately so use these lengths if they work for the part being desiged. Use the CAD Thickness and CAD Bend Radius numbers in the table below in the SolidWorks CAD files. The "Stretch Length" is the amount the part gets longer after it is bent. Subtract this number from the final part length to get the flat part length. For example, for a 10" long piece of 0.060 sheet metal with a 1" long flange, the flattened part should be 10.891" long before it is bent (10" + 1" - 0.109"). The lengths are outside lengths. If the example part is placed on a table, the top edge of the 1" flange will be 1" above the table surface.

Nominal Thickness : Actual Thickness : CAD Thickness : CAD Bend Radius : K-Factor : Magic Flange Length : Stretch Length

We use various types of aluminum. The most common are 5052-H32 for sheet metal, 7075-T6 for shafts and other smaller parts that need to be very strong, and 6061-T6 for everything else. Identifying which type a piece of stock is can be important, but luckily the ends come painted in standardized colors. Here is a table:

| 2011 | Brown |

| 2014 | Gray |

| 2017 | Yellow |

| 2024 | Red |

| 2219 | Yellow/Blue |

| 6061 | Blue (often very dark and easily confused with black 7075) |

| 7049 | Purple/Blue |

| 7050 | Yellow/Orange |

| 7075 | Black (easily confused with dark blue 6061) |

- Drill Bits from McMaster Carr - US Tap and Drill Bit Size Table, Tapping and Clearance Drills for Fractional Machine Screws, and Drill Bit Size Decimal Equivalents

- 29045A753 LONG−LIFE TIN−COATED HSS JOBBERS' DRILL BIT, WIRE GA 30,2−3/4"OAL,1.4"DRILL DEPTH,135DEG POINT - For 1/8" Al Rivets

- 29045A732 LONG−LIFE TIN−COATED HSS JOBBERS' DRILL BIT, WIRE GA 11,3−1/2"OAL,2.0"DRILL DEPTH,135DEG POINT - For 3/16" Al Rivets

- 30595a35 Gen Purpose Uncoated HSS Jobbers' Drill Bit Size E (1/4" dia), 4" L Overall, 2.4" Drill Depth, 118 Deg Point - for drilling through holes for 1/4" bolts.

- 30595a36 Gen Purpose Uncoated HSS Jobbers' Drill Bit Size F, 4" L Overall, 2.4" Drill Depth, 118 Deg Point - for drilling close fit clearance holes for 1/4" bolts.

- 30595a37 Gen Purpose Uncoated HSS Jobbers' Drill Bit Size G, 4" L Overall, 2.4" Drill Depth, 118 Deg Point - for drilling close fit clearance holes for 1/4" bolts.

- 30585A17 Gen Purpose Uncoated HSS Jobbers' Drill Bit Wire GAUGE #7, 3-5/8" Oal, 2.1" Drill Depth, 118Deg Point - tap drill bit for 1/4" - 20 threaded bolts.

- 8870A28 Gen Purpose Uncoated HSS Jobbers' Drill Bit 17/64", 4-1/8" Oal, 2.5" Drill Depth, 118 Deg Point

- 2939A21 High-Speed Steel Extended-Reach Drill Bit Uncoated, 17/64", 12" Overall Length, 8.5" Drill Depth

- T-Handle Ball end Allen Wrenches - 3/16 for socket head, and 5/32 for button 1/4" - 20 bolts

- Fisher Price Motors: Michael bought screws for them. They take a metric thread. He thinks they were the M3, .5 mm pitch, 8 mm long socket head cap screws, McMaster Part Number 95263A122. Washers, McMaster Part Number 91202A22. These were purchased between SVR and Atlanta in 2010. The size and part number info came from the 2010-3-29 Schuh McMaster-Carr 2010Robot 221.00.pdf (download to view) receipt. Michael 7/11/10

-

Scott: do you know which is better, latex or rubber surgical tubing?Sent at 3:52 PM on Fridayme: no. I don't know which one.Scott: okSent at 3:53 PM on Fridayme: I googled on "latex or rubber surgical tubing - which is best" and found some info at http://www.aerofoam.com/hosemonstercare.html that talks about mandrel dipped latex tubing being the best. I don't know if that is a purchase option or not.Sent at 4:03 PM on Fridayme: This one looks promising: http://www.primelineindustries.com/me: It sounds like latex and rubber are two different names for latex rubber tubing. Michael SchuhSent at 4:04 PM on Friday