CHOCOLATE WRAPPING MACHINE - a-division-2019-20-odd/Repo-03 GitHub Wiki

INTRODUCTION

chocolate wrapping machines are equipment you can use in packing different types of chocolates and candies.chocolate wrapping machine decreases the time needed to wrap the the chocolates and increases the accuracy of the wrapping and is cost efficent too. This project pulls from our knowledge in kinematics, dynamics, 3D modeling, tolerance analysis, material selection, manufacturing techniques, and design of components. From doing this project we will learn how to apply all of these concepts together to solve real world problems.invention of this not only reduced labour work but also improved the hygiene of the chocolate wrapping part and in long term ,the machines will boost chocolate production and maximize the profit .It also brought the concept of decorating chocolates and improving the aesthetic value for better sales

History

Gilbert Chocolates, which is based out of Jackson, MI, has requested to design a chocolate wrapping machine for their chocolate bars the company used to wraps the bars by hand, which takes about 1 minute. the machine must be able to wrap both the aluminium foil and paper sleeve around the bar in 20-30 seconds. To achieve this, the machine must have a short setup time, and a short wrapping time. Also, there is a lack of consistency when wrapping by hand, and the machine is designed to not make mistakes, which would require re-wrapping.

principle (on which chocolate wrapping machine works)

Principles of chocolate wrapping machine depends on the types of machines used and even on the basis of ways of wrapping

Principles of the Chocolate Coin Wrapping Machine

Whenever you are purchasing a chocolate coin wrapping machine, you have to consider the following features. i. Production capacity and the wrapping arrangements. ii. Total power requirements iii. Machine dimensions including the weight and size. iv. Touch screen and PLC control system v. Sensors that can automatically detect the presence of chocolate and paper. vi. Flexible die mould system which you can change to different sizes. vii. Proper certification such as CE and ISO that ensures the machine is of high quality.

Principle of the Chocolate Fold Wrapping Machine

The machine features different holders with gears that can control the speed of transfer of the folders. It also features a special adhesive group to reinforce the scale, especially on the horizontal outlet. Apart from that, most of the machines are fully automatic thus increasing the wrapping efficiency and accuracy. The automatic system also features an automatic malfunction alarm system to stop the machine in case of a malfunction. Additionally, the machine allows for customization giving you the chance to determine: i. The wrapping capacity of the machine ii. Dimensions in terms of gross weight, size, film width and shape of the products to wrap. iii. Electrical power unit and the compressed air or pneumatic system.

principle of the Chocolate Foil Wrapping machine

The machine features a noxious material for the parts that are in direct contact with the chocolate. It also has a cam mechanism system that depends on a 3-phase synchronous motor to drive the operations. The wrapping disk of the machine has a number of pistons depending on the machine that can move intermittently. It also features rapid replacements of the supply wheel of the wrapping papers or foils. Apart from that, it also has an automatic shower lubrication system. The main lubricant is oil which you can find in a removable pallet. As a buyer, you will have to consider the following technical specifications featured in all chocolate foil wrapping machines. i. Wrapping capacity of the machine ii. Power supply system iii. Dimensions in terms of weight, packing size, packing paper size including thickness and width.

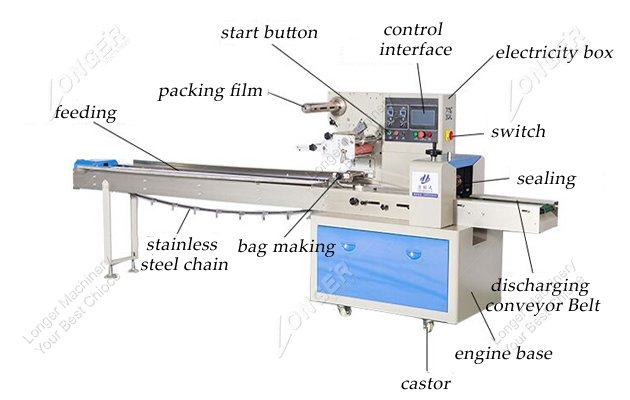

components of chocolate wrapping machine

The major parts of the chocolate wrapping machine are:

- PLC control system complete with a touch screen for easy display of the control parameters.

ii. Shower lubricant distribution system

iii. Removable oil pallets

iv. Distribution system with conveyor belts, gears, and motors to drive the machine operations.

v. Wrapping system with wrapping disks and pistons for better flexibility.

vi. Feeder system that feeds the machine with the chocolate and the wrapping papers.

vii. Automatic printing system

viii. Automatic sensors and alarming system that improves the safety of the machine.

working of chocolate wrapping machine

Step One: Preparing the Main Ingredients

In this case, the main ingredients are the chocolate and the wrappers.

In a complete production line, you will find different types of machines performing different functions.

In this case, the chocolate wrapping machine receives complete chocolate from the production line.

At the same time, you will load the chocolate wrappers onto the wrappers hopper.

Ensure that the machine is in proper working condition before switching it on.

Step Two: Wrapping the Chocolates

There are different types of wrappers that you can use in the wrapping process.

The wrapping process also varies and follows different wrapping stages.

In this case, we are going to look at the single stage primary wrapping of chocolates.

As soon as the chocolate reaches the wrapping stage, the machine automatically wraps it into a wrapper.

The wrapper may be in the form of a foil, polythene, or a fold piece of paper.

Step Three: Cutting the Chocolates Wrappers

After wrapping the chocolate, it moves it to the next stage where the machine will cut the wrappers to size.

After that it moves the wrapped chocolates on to the sealing stage.

The wrapping process may be in the form of:

Step Four: Sealing the Chocolate Wrappers

At this point, the machine will automatically seal the loose ends of the chocolate wrappers.

The sealing may be in form of laser heating, or the use of glue.

Step Five: Printing the Chocolate Wrappers

The wrapping process comes to an end with the decoration of the wrappers.

The printers make different impressions and designs on the wrappers.

It also includes the manufacturing and expiry dates on the wrappers.

Step Six: Packaging the Chocolate

As soon as the wrapping is complete, it is important to inspect the integrity of the wrapper.

The wrappers should have complete seals that are easy to open.

You should also confirm the prints on the wrappers making sure they meet your requirements.

After that, the machine can automatically package them into different cartons.

Uses of chocolate wrapping machine

i. Wrapping different types of chocolates such as solids, inclusions, wafers and cookies, and other pure types of chocolates.

ii. Provides you with different options for wrapping chocolate such as using foils and folds, single or double stage wrapping.

iii. Packaging the chocolate in different materials after wrapping.

iv. Since the machine is automatic, it is capable of wrapping chocolates within a short period thus saving on time.

v. The machine is flexible and you can easily adjust it to fit different packaging sizes depending on your specifications.

vi. You can also use it to package chocolate of different dimensions in terms of chocolate sizes.

vii. With a complete printing system, you can accurately label the chocolates after wrapping. You can use a chocolate wrapping machine for the following functions

ways of packing chocolate

There are different ways you can use to wrap and package chocolates some of the most common ways of wrapping chocolate includes:

Banding

This involves wrapping a band of wrapping materials around the chocolate also,the selling process cab either be in the form o the heat or glue.the banding paper or film has to be relatively thick or stiff such as high density polythene

Sleeve wrapping

this involves the use of one or two reels of film to form or enrobe a web around the chocolate.You may use a loose piece of film and then shrink it tight by applying heat

The wrapping material is use can be low of density polypropylene material with a thickness of about 30 to 120 microns

Fold wrapping

In this case,the machine wraps an aluminum or paper around the chocolate without a heat seal.It is a wrapping method you can employ when you think there is a danger of heat destroying the chocolate

Twist wrapping

It involves twisting the ends of the chocolate wrapper to seal it.You will use stiff film and cellphone that can produce a cracking sound whenever you unwrap the chocolate.

Fold wrapping

It involves wrapping cylindrical chocolate and heat sealing the ends of the seal.In such a case ,you will use a heat sealable film such as polypropylene

Foil and band wrapping

Normally ,it involves wrapping chocolate around an aluminum foil first before wrapping a piece of paper around the aluminum foil

Pleat wrapping

this process involves the formation of pleats around the chocolate and then using a lab to seal the wrap.You can use it to wrap non rectangular or circular chocolate products. The chocolate wrapping style of choice will depend on the type of chocolate you intend to pack

Stages of wrapping

single stage primary wrapping

It involves wrapping the chocolate in one or two packing materials in one operation.you can also identify it as a mono pack.Also you can either use a fold wrapping machine or a horizontal flow wrapping machine

Two stage primary wrapping

the two stages primary wrapping involves the use of two packaging materials.Apart from that,you will pass the chocolate through two consecutive wrapping steps either as multi packs or mono packs

to achieve this,you can use a fold wrapping machine to wrap the chocolate g

Secondary wrapping

Secondary wrapping is the wrapping of chocolate materials that already have a primary wrapper around them.The main secondary wrapping materials that you can use include:

1.OPP or PP film wrapping materials 2.Cellphone wrapping materials 3.paper wrap or a cardboard label In this case,you can either create a multipack or a mono pack The main machines in use are the fold wrapping machines and the horizontal flow wrapping machines

Tertiary wrapping

The wrapping process involves placing the wrapped chocolates in open or closed carton trays or cartons.You can then seal the cartons with cellphone for extra security of the chocolates.In this case,you will use a cartoning machine

In this case,you will use a cartoning machine

Final wrapping

This is the final stage of packaging before rekeasing the chocolate for dispatch to different locations.It invloves the use of downstream equipment in the production chain such as shipping pallets or cartons.

Types of Chocolate Wrapping Machines

You have the freedom of choosing the type of chocolate wrapping machine of interest.The details on the main types of chocolate wrapping machines are as follows.

Chocolate Coin Wrapping Machine

This is a type of device that you can use in wrapping chocolate that assumes the shape of a coin.You can opt for the modern type of machine which substitutes packing with single chromo paper for colored bristol paper.

It has a servo intelligence control system that operates the machine with a lot of ease.It produces very low noise thus making the working environment more comfortable for the operators. It also fully automatic with a direct connection to the chocolate coin production line.The processes of forming, feeding, filling and sealing of the chocolate coins are all automatic. The machine has an industrial touch screen that acts as an interface between you and the machine.The touch screen displays all the parameters and the menu making it easy for you to operate the machine.The machine has sensors that will automatically stop the machine in case of any issues thus enhancing safety.

Chocolate Foil Wrapping Machine

t is a machine that you can use in wrapping ellipse chocolate or ball chocolate using different types of foils.

t is a machine that you can use in wrapping ellipse chocolate or ball chocolate using different types of foils.

Advantages of the Chocolate Foil Wrapping Machine

i. It adopts a frequency converter technique that converts the wrapping dimensions of the machine frequently.

ii. It is user friendly with a complete PLC control system making it easy to operate.

iii. The machine wraps the chocolate with high speed and gives it a wonderful appearance.

iv. Very low operational costs since it is automatic and you do not need a lot of man power.

Key features of the Chocolate Foil Wrapping machine

The machine features a noxious material for the parts that are in direct contact with the chocolate.

It also has a cam mechanism system that depends on a 3-phase synchronous motor to drive the operations.

The wrapping disk of the machine has a number of pistons depending on the machine that can move intermittently.

It also features rapid replacements of the supply wheel of the wrapping papers or foils.

Apart from that, it also has an automatic shower lubrication system.

The main lubricant is oil which you can find in a removable pallet.

iv. Reducing the downtime of the machine where the machine stays idle by replenishing the supply of raw materials.

chocolate bar wrapping machine

It is a machine that you can use in packaging chocolate bars in paper aluminum or cardboard wrappers.The machine also hermetically seals the wrappers for the ultimate convenience in storage and use.

Some of the chocolate bar wrapping machines include:

1.Chocolate bar fold wrapping machine

2.Chocolate bar horizontal flow wrapping machine

3.Chocolate bar cartoning machine

It is a machine that you can use in packaging chocolate bars in paper aluminum or cardboard wrappers.The machine also hermetically seals the wrappers for the ultimate convenience in storage and use.

Some of the chocolate bar wrapping machines include:

1.Chocolate bar fold wrapping machine

2.Chocolate bar horizontal flow wrapping machine

3.Chocolate bar cartoning machine

Some of the major advantages of using the chocolate wrapping machines include:

i. It guarantees the highest quality of wrapping with the best designs.

ii. It also offers different wrapping solutions in the form of bands, envelopes, and cubes among others.

iii. The machine has special features that increase the ease with which you can operate the machine.

iv. It is fully automatic thus speeding the process of wrapping the chocolate bars.

v. It has an extremely gentle chocolate bar handling procedure thus avoiding breakages

Conclusion

Having a chocolate wrapping machine in the chocolate production line will ensure you get the maximum profit.

It is a machine that will add a lot of value to the product package.

The good news is that you can get you’re a custom chocolate wrapping machine at a good cost.

Do not wait any longer.

Get in touch with your supplier and order your custom chocolate wrapping machine.