Lesson 7 Liquid Meassuring For Boat - Water-Monitor/IoT-Portfolio-FJS GitHub Wiki

Side-project: Finding the perfect sensor for testing liquids on a boat

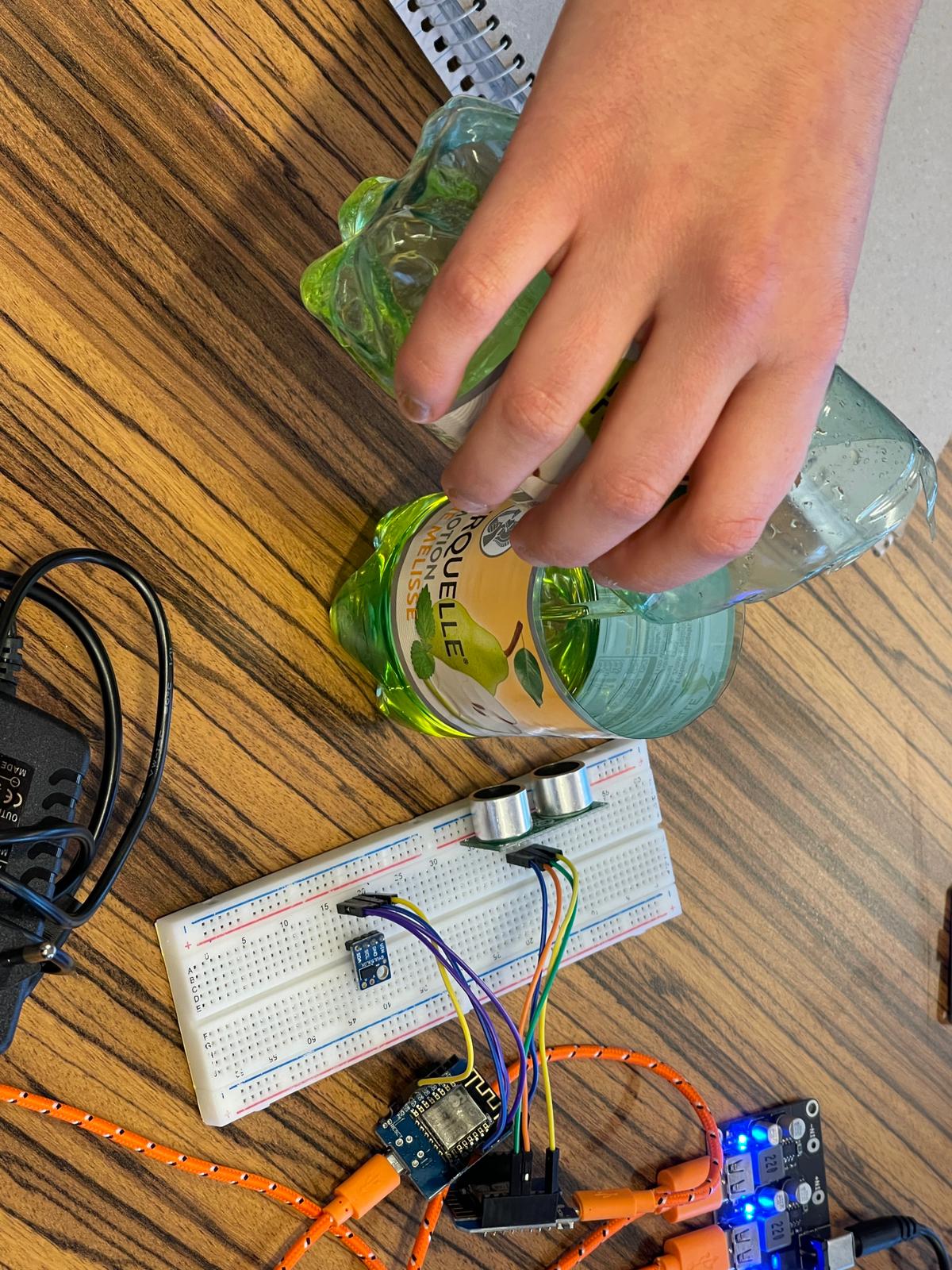

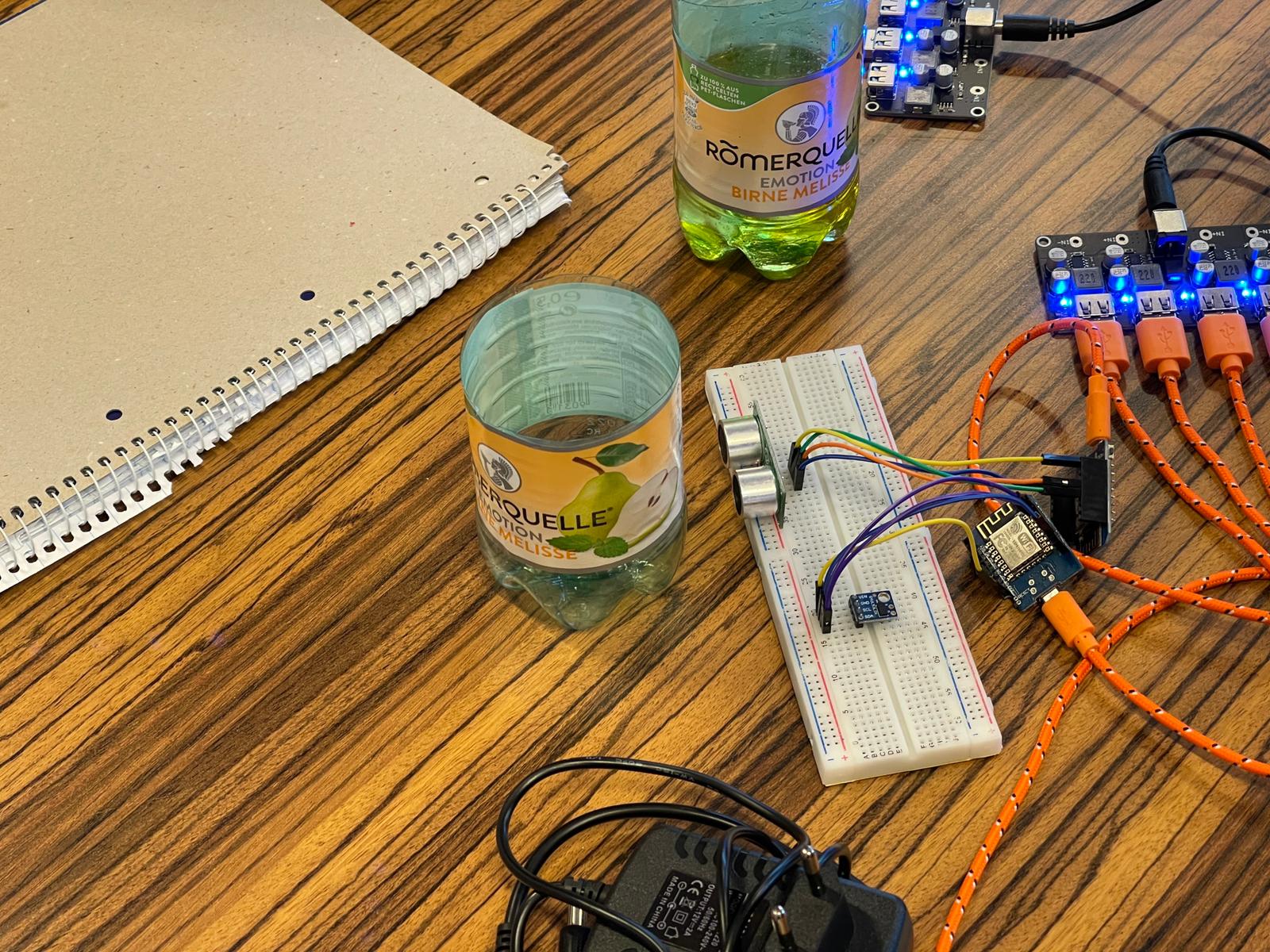

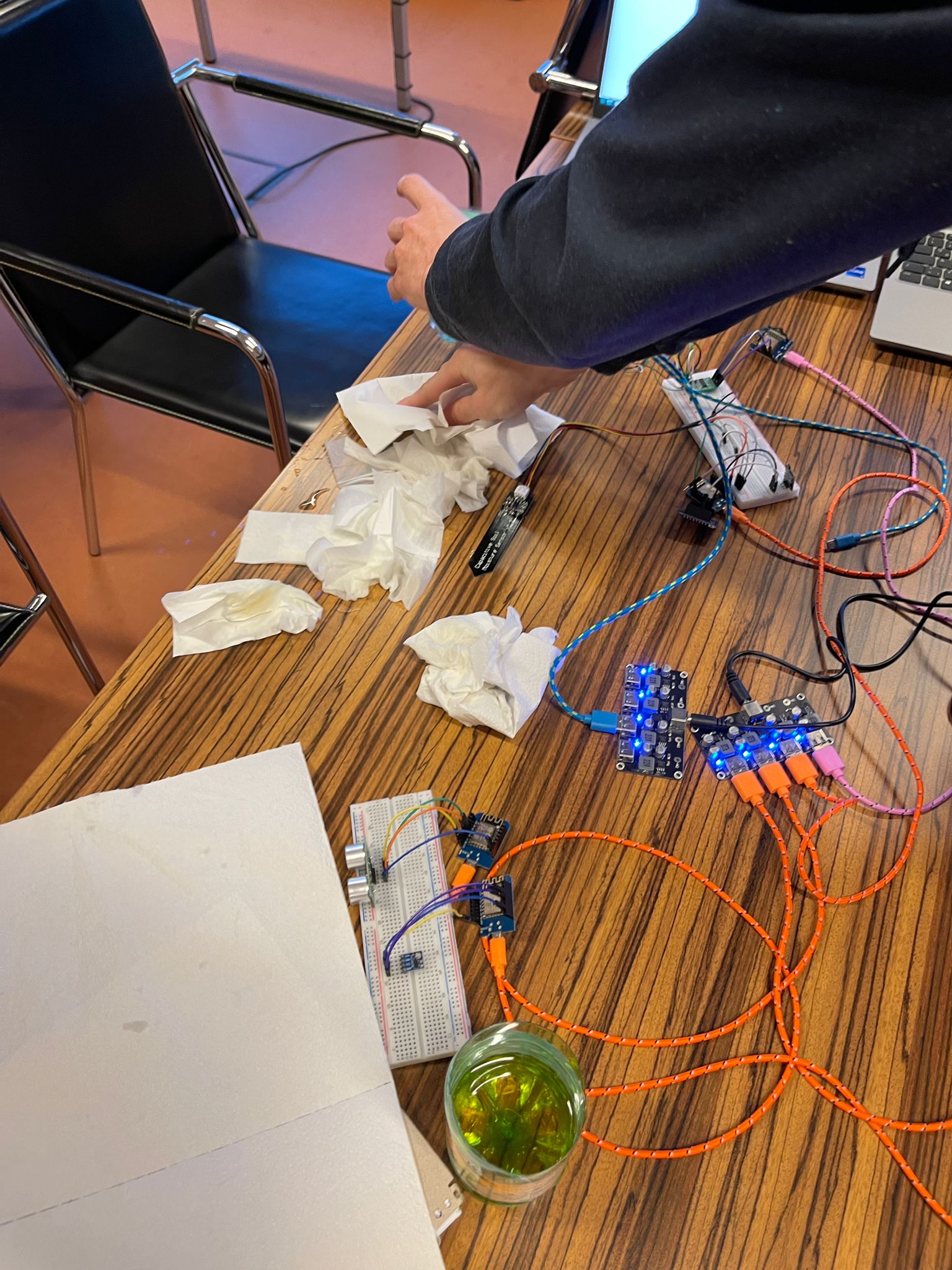

In this project, we were giving the task to bring 3 bottles, 3 different liquids (dirty water, clear water and oil), a scissor, cardboard and a glue. We never used the last 3 things but that's because we couldn't use all the sensors. In the task, we were supposed to get 5 different sensors working and figure out which would be the most suitable for testing liquids on a ship.

We were given 5 different sensors:

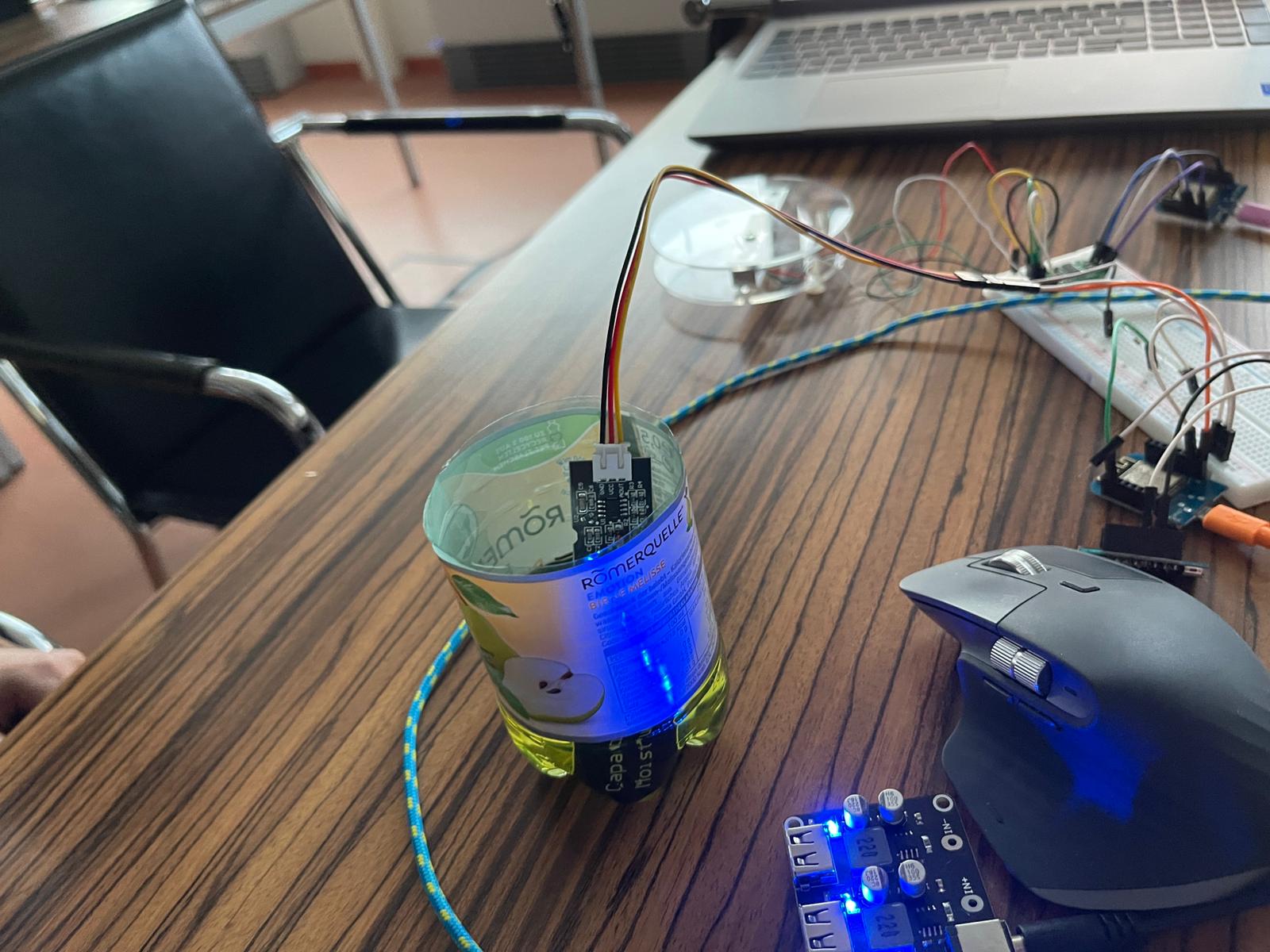

- A conductive sensor (moisture sensor)

- An acustic sensor (ultra dynamic distance sensor)

- An optic sensor (laser sensor)

- A weight sensor (scale)

- A magnet sensor (hall sensor)

The moisture sensor was already done from the previous task. Stijn & Fadi were working on the acustic & optic sensors, while I (Johanna) was building up the scale. In the end, Stijn and I tried to get the hall sensor working and did a lot of troubleshooting. Fadi also created a dashboard on node-red were we all sent the values of our sensor.

Setting up all the sensors was not a big challenge. However, we struggeled a lot with the hall sensor. The hall sensor is very similar like the moisture sensor: It needs an analog command in the setup.cpp file and should output differnet values, depending were its magnet is. Sadly, the hall sensor never changed its values regardless were the magnet is. We tried removing and changing some wires, but the values stayed the same. It was always something between 9 and 11 units. So, we had to give up on the hall sensor and focused on the other work.

While measuring our values with the oil, dirty water and clean water, we realized that the values on the dashboard are not synchronized with the actual current values anymore. We figured out that all the sensors, were sending out too much information at once and we never added a treshold or anything to make them limited. After restarting and limiting our sensors, we managed to keep on working with measuring.

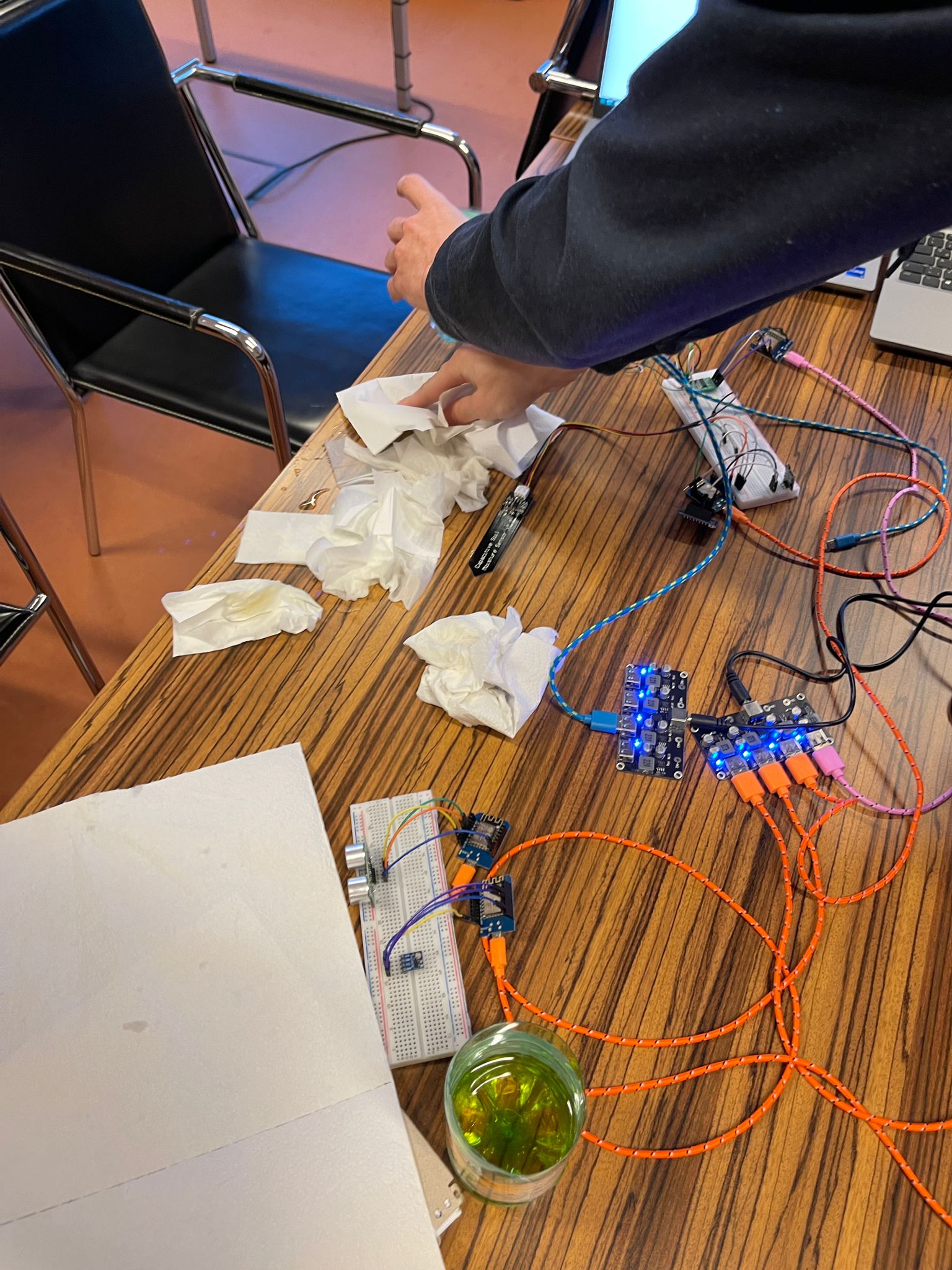

Everything went fine, but then we spilled one of the bottles of water, had to secure all the sensors and clean everything up. We were just glad that it only happend with the bottle of water and not with the oil.

After we finished measuring the last few values, we came to the conclusion that some sensors are better to trust than others.

- The laser sensor was the least acurate one

- The scale was quite useful and precisely

- The Moisture sensor would know the difference between oil and water, but not between oil and air...

- The acustic sensor was also quite okay

Summary

We did well in measuring the values with all the sensors, but we never really connected them with real scenarios on a boat. Ulrich helped us and discussed with us, which sensor would be the most effective one. Without him, we wouldn't manage to figure out a solution:

- The scale would be nice to use, but in real life we won't be able to use it, since it has to be underneath big countainers and it is not easy to put them there.

- The acustic sensor was also nice, but it cannot get wet. It can also not work with some securements like having a screen between it and the liquid.

- The Moisture sensor is not an optionn since it cannot detect a difference between oil and air. Therefore, we would never know if the container is just oil or empty.

- The laser could actually solve the problem. It is just very unfortunate that is was so inacurate during the testing time. We need to put in more effort and time to make it usable for a ship.

What do we need to make it usable for the boat?

We need more sensors at a time with average output in the end. They all have to be water- and oilproof and we need enough space for better cable management. Also, we should send data only every 5-10 minutes to the dashboard so it won't overwhelm again.