STV Dashboard and Telemetry PCB Design - ScuderiaTorVergata/Electronics-PCB-Design GitHub Wiki

Overview:

Scuderia Tor Vergata is the official Formula SAE team for the University of Rome Tor Vergata, based in Rome, Italy. The purpose of the competition is to design and build a formula-style prototype to compete in competitions around the world. This year, the electronics department took on the responsibility of redesigning the dashboard board for the vehicle.

The design of an HMI (Human Machine Interface) electronic board for a formula-style race car is a critical process to ensure efficient and safe driving. The HMI must provide an intuitive and easily accessible interface for the driver, allowing them to monitor the vehicle's performance and control its functions.

The HMI electronic board includes a 4.3’’ high-definition display that provides a clear and sharp display of driving information. In addition, it is equipped with communication protocols necessary to interact with other controllers inside the car in order to control and receive information from them. The ultimate goal is to monitor all vehicle performance in real-time.

The design of the HMI electronic board must be resistant to vibrations and mechanical stresses, common in a race environment, which is why strong integration with the container design in which it must be contained is required. Additionally, the board should be designed to consume the least amount of energy possible to ensure that the vehicle's battery lasts for the entire duration of the race.

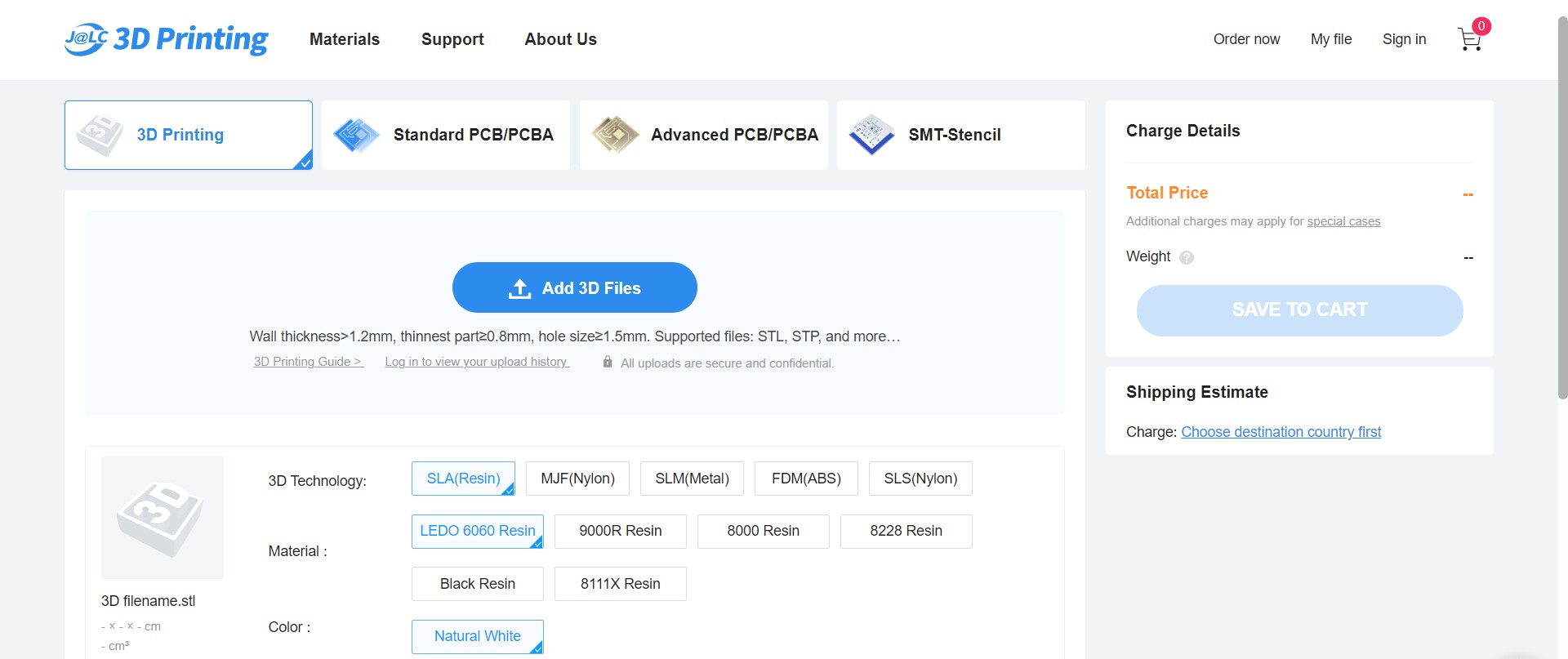

Electronic Design:

The board is based on an ESP32 microcontroller with Lora, Wi-Fi, and Bluetooth connectivity. Integrated and accessible communication peripherals are:

• 1x CAN BUS for communication with all other controllers in the car

• 3x UART, respectively for the management of the display, wireless telemetry, and debugging

• 5x ANALOG INPUT, for the integration of additional sensors

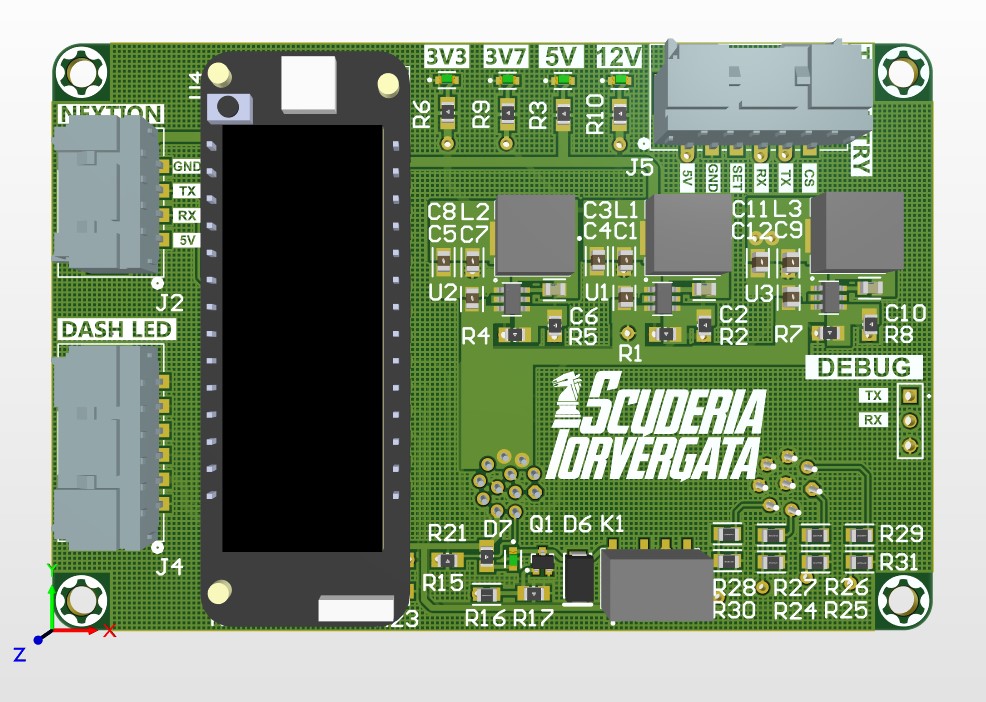

In addition, there is a second board placed around the display that includes LEDs useful for highlighting specific states of the vehicle's operation, such as warning lights for temperature and pressure of certain vehicle components.

The dashboard is responsible for reading all telemetry information via CAN BUS from the controller and subsequently displaying it on the display and transmitting it to one or more PCs in the Box in Real Time to allow the driver and engineers to control all parameters while the vehicle is in motion.

Mechanical Design:

The design of a case for an electronic controller on a race vehicle requires strong attention to resistance and durability. The case should be made of lightweight materials but resistant to vibrations and mechanical stresses. The design should also ensure good heat dissipation to prevent electronic controller overheating.

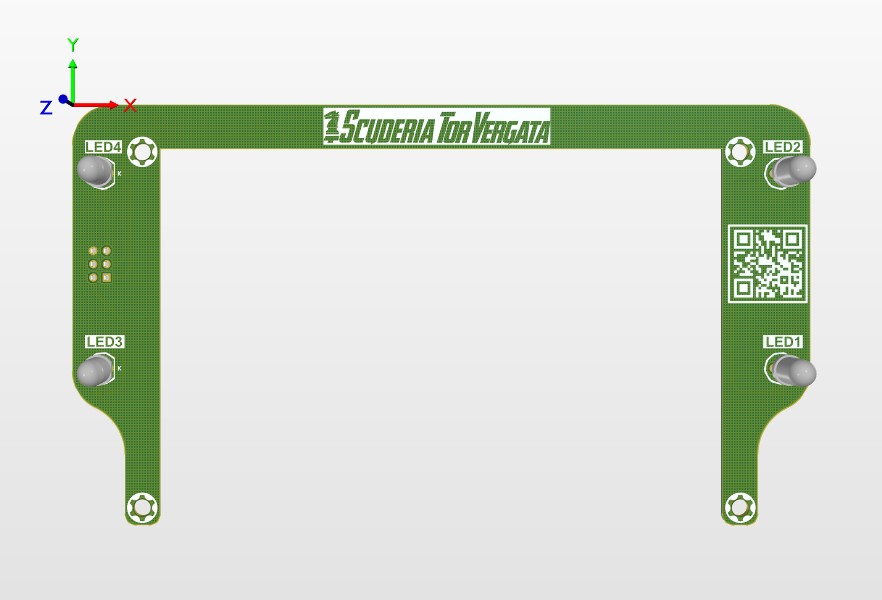

The use of 3D printed materials for electronic board cases has become increasingly common in the race automotive industry. These materials are lightweight, resistant, and allow for personalized and precise case design. Additionally, 3D printing allows for low-cost prototyping and production, reducing product development times. 3D printing technology also offers greater design freedom, allowing for complex and customized shapes that may be difficult or expensive to produce with other production techniques.

PCB and 3D design with JLCPCB

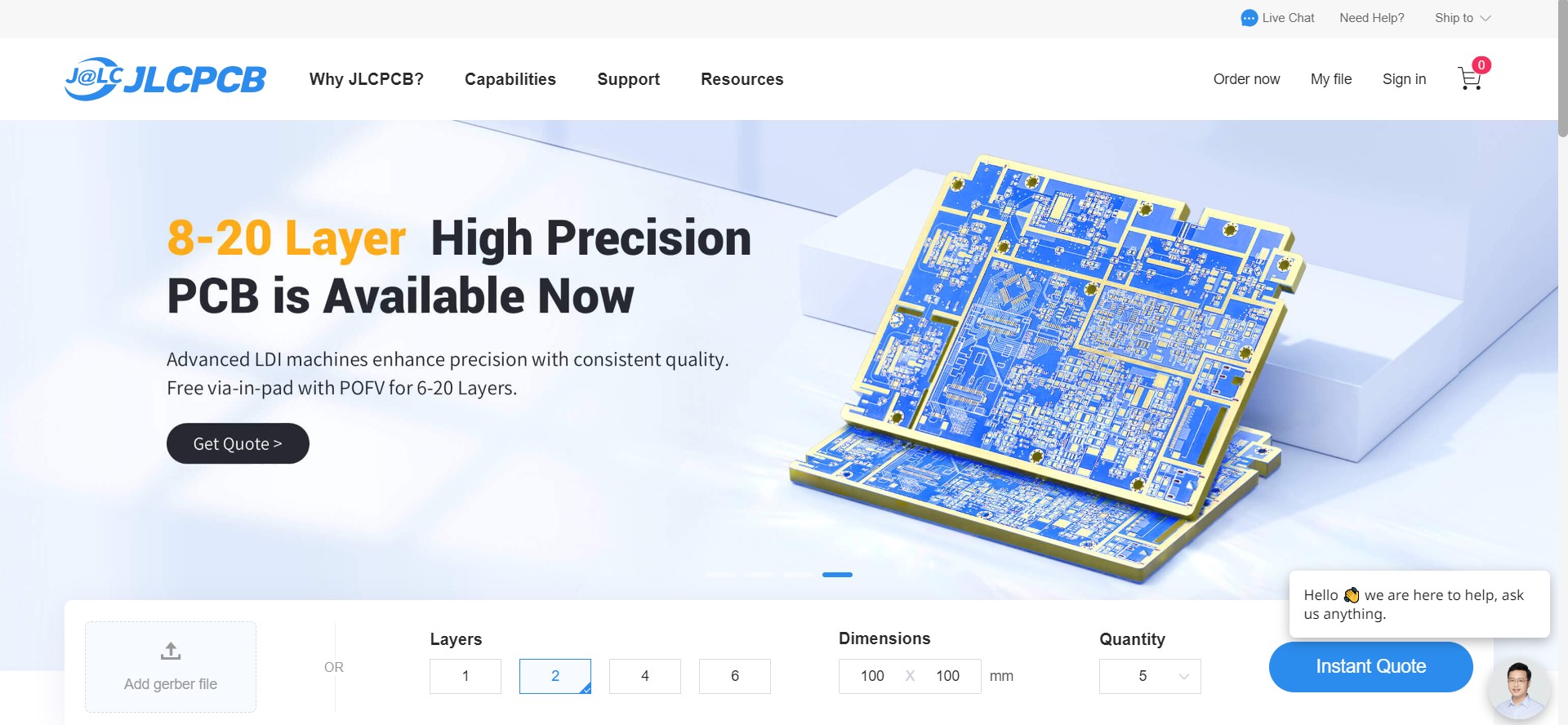

JLCPCB (https://jlcpcb.com/) is a company that focuses in prototyping PCBs and SMT assembly. JLCPCB guarantees quality, high precision, and fast board production, which was the primary reason we selected this company for the PCB production.

JLCPCB's website (https://jlcpcb.com/) offers a service that allows users to upload the Gerber file required for manufacturing, after which, there are numerous configurations that can be managed to meet the needs of the user, such as layers, delivery format, pcb color, and so on.

One of their standout features is that users can include a pcb stencil in their order and configure it on the website (https://jlcpcb.com/).

Thanks to JLCPCB who made the PCBs for us. They also provide us a stencil for SMT device that help us to solder the PCB correctly.

Furthermore, through JLCPCB and their 3D printing service, we were able to create the final copy of the case that will contain our control unit. Their wide selection of materials allowed us to make the best choice for our mechanical requirements and ensure the proper functioning of the entire system.