6.VIRTUAL IMPLEMENTATION - Q-Div-2022-2023-Odd/Repo-10 GitHub Wiki

| Bill of materials | ||||||

|---|---|---|---|---|---|---|

| Sl.no. | Name of the material | Quantity | Material with which part is madeof | Description about part | Fabrication process if needed | |

| 1 | 3D printed Plates | 3 | plastic | 20cm diameter and 1cm thick | 3D printing | |

| 2 | 12V DC gear motor | 2 | 12 V 300mA | |||

| 3 | 5V voltage regulator | 1 | 5V | |||

| 4 | Spacers | 4 | plastic | 8mm diameter and 5cm long | ||

| 5 | IR Sensors | 3 | ||||

| 6 | DC Power jack | 1 | ||||

| 7 | small wood screws | 10 | ||||

| 8 | 2.5 inch long screws | 5 | 2.5 inch long | |||

| 9 | 2 inch long screws | 10 | 2 inch long | |||

| 10 | 1.5 inch long screws | 10 | 1 inch long | |||

| 11 | nuts and bolts | 20 | ||||

| 12 | Bearing and holding assembly | 1 | plastic | |||

| 13 | Bottle guide | 1 | rubber | |||

| 14 | Stepper motor holding assembly | 1 | ||||

| 15 | Linear sliding bearing for 8mm shaft | 2 | ||||

| 16 | NEMA 17 stepper motor | 1 | ||||

| 17 | 20 teeth pulley | 1 | 20 teeths | |||

| 18 | Spring | 1 | ||||

| 19 | 280mm timing belt | 1 | 280mm | |||

| 20 | 6 inches shaft | 2 | rubber | 6 inch | ||

| 21 | 12 inches long shaft | 2 | steel | 12inch | ||

| 22 | 60 teeth pulley | 1 | 60 teeths | |||

| 23 | mounting brackets | 5 | ||||

| 24 | Air pump | 1 | ||||

| 25 | Air solenoid valve | 1 | ||||

| 26 | 12 V Waterpump | 1 | 12V | |||

| 27 | Conveyor belt 50 cm | 1 | rubber sheet | 50cm | stitching | |

| 28 | conveyor side walls | 2 | acrylic sheet | 55cm 10cm1cm | cutting and sanding | |

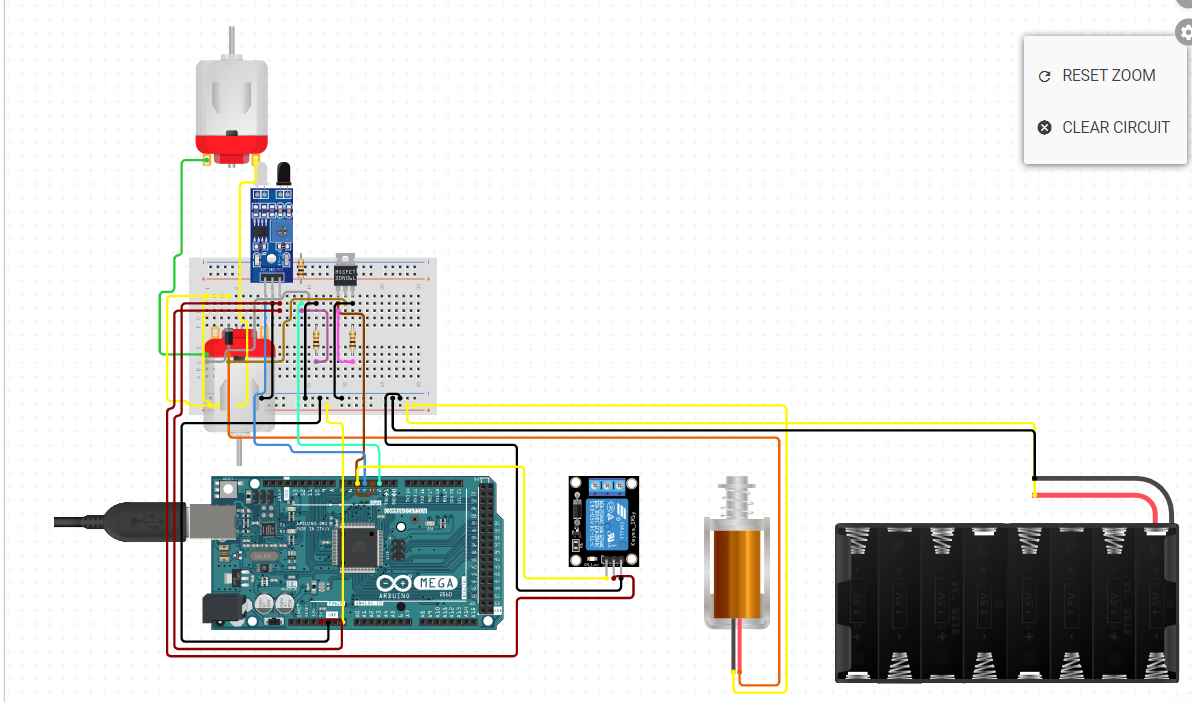

| 29 | Arduino Mega 2560 | 1 | ||||

| 30 | Stepper motor drive | 1 | ||||

| 31 | Male and female pins | 20 | ||||

| 32 | 1k ohm resistors | 6 | ||||

| 33 | 10k ohm resistors | 1 | ||||

| 34 | 220 ohm resistors | 1 | ||||

| 35 | 12V DC relay | 3 | 12V | |||

| 36 | led | 2 | 5mm | |||

| 37 | transistors | 5 | ||||

| 38 | tactile switch | 1 | 12mm | |||

| 39 | 12V buzzer | 1 | 12V | |||

| 40 | 220 microfarad capacitor | 2 | 220µF | |||

| 41 | diodes | 5 | ||||

| 42 | voltage stepdown convertor | 1 | ||||

| 43 | nob | 1 | ||||

| 44 | siringe 20ml | 2 | plastic | 20 ml | ||

| 45 | pipe | 2 | rubber | 10mm diameter and 50cm long | ||

| 46 | Container | 2 | acrylic sheet | cutting and bending | ||

| 47 | cap despensor | 1 | plastic | 3D printing | ||

| 48 | foundation | acrylic or foam sheet | cutting and bending | |||

Coefficient of friction=0.3

Volume=1000cm3

Density=1.18 g/cm3

Mass=1.18 kg

Horizontal Force

=0.3* 1.18* 9.81

=3.47 kg-cm

Torque=F*r

= 3.47* 1 =3.47 kg-cm

Factor of safety=1.5

Torque

= 3.47* 1.5

=5.20 kg-cm

rpm of motor= 30 rpm

Volume=525 cm3

Density=1.18 kg/cm3

Mass=1.01 kg

Horizontal Force

=0.3* 1.01* 9.81 =2.97 kg-cm

Torque

=2.97* 1=2.97

= 2.97* 1.5=4.45 kg-cm

rpm of motor =30 rpm

2 DC motors are used hence,

2*300=600 mA and 12V

Factor of safety=1.2

600*1.2= 720 mA

Hence the adapter should be 12V and 1A