6.0 Virtual Implementation - P-Division-2022-2023-Odd/Repo13 GitHub Wiki

6.1 3D Modelling

For Punching

Base Sheet

Crank

Slider

Punch

L Clamp

Motor Holder

For Dispensing

Punching Base

Pinion

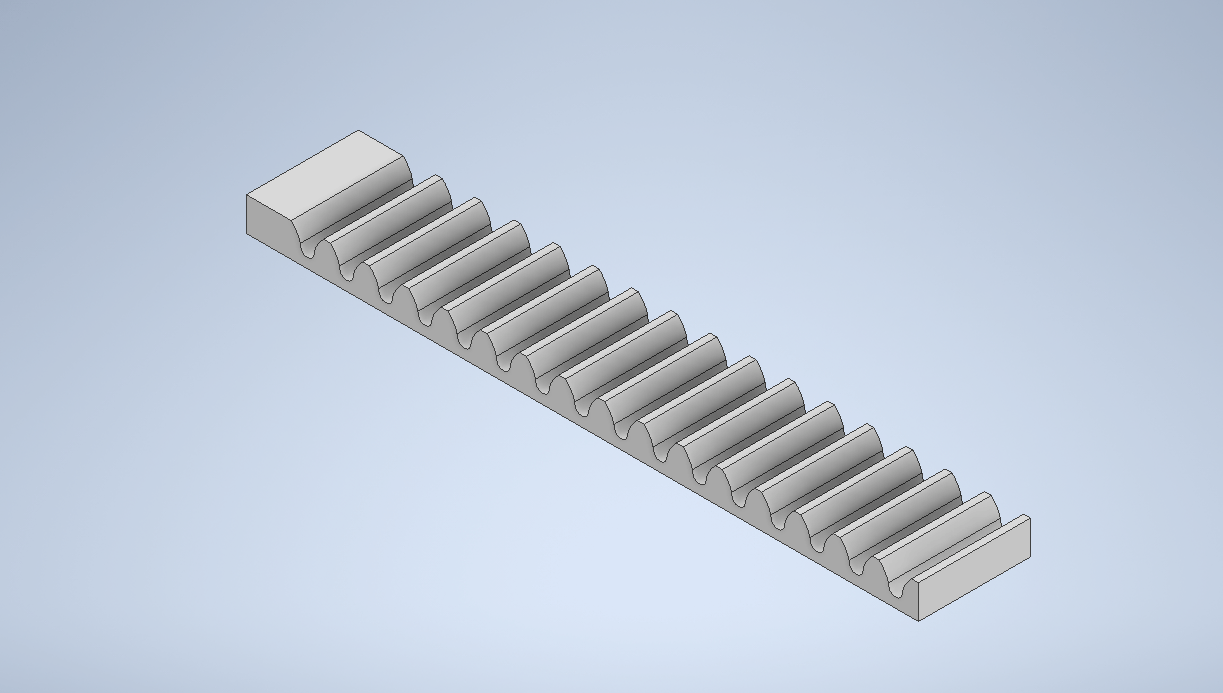

Rack

Rack And Pinion

Stack Holder

Punching Base

Stepper Holder

Rack Support

Complete System

6.2 Circuit Design

Circuit For Punching

Circuit For Dispensing

Circuit Of Entire System

6.3 Flow Chart

Flowchart For Punching

Flowchart For Dispensing

Flowchart For The Entire System

6.4: Bill of Materials

Bill of Materials for Punching

| SL. No. | Parts Required | Quantity | Specifications |

|---|---|---|---|

| 1 | Foam Board Base (with 5mm diameter hole at the centre) | 1 | 200mm x 250mm x 30mm |

| 2 | Acrylic Short link | 1 | 110mm x 18mm x 4mm |

| 3 | Acrylic Big Link | 1 | 225mm x 18mm x 4mm |

| 4 | L Clamp | 1 | - |

| 5 | Bolts | 4 | m5 25 cm |

| 6 | DC Motor | 1 | 60 RPM |

| 7 | DC Motor relay | 1 | 2 channel 5v relay |

| 8 | IR Sensor | 1 | HC-SR505 |

| 9 | Adapter | 1 | 12V 1A adapter |

| 10 | Nylon Rod | 1 | 8 mm |

| 11 | LEDs | 2 | Red and Green |

| 12 | Spring | 1 | 2cm x 2cm |

Bill of Materials for Dispensing

| SL. No. | Parts Required | Quantity | Specifications |

|---|---|---|---|

| 1 | Rack and Pinion | 1 | - |

| 2 | L Clamp | 2 | 40 mm x 70 mm and 35 mm x 70 mm |

| 3 | IR Sensor | 1 | HC-SR505 |

| 4 | Nylon Rod | 1 | 250mm x 12.5mm x 10 mm |

| 5 | Adapter | 1 | 5V 1A |

| 6 | LEDs | 2 | Red and Green |

| 7 | Stepper motor | 1 | 28byj-48 |

| 8 | Stepper motor driver | 1 | ULN2003 |

Bill of Materials for Outer Body

| SL. No. | Parts Required | Quantity | Specifications |

|---|---|---|---|

| 1 | Foam board sides (5mm) | 4 | 200mm*250mm |

| 2 | Foam board base (10mm) | 1 | 100mm*150mm |

| 3 | Foam board top (3mm) | 1 | 100mm*150mm |

| 4 | Buzzer | 1 | 2kHz noise |

6.5 Mechanisms And Resource Specifications

Motor Sizing: DC Motor (Punching):

Volume of linkages = 241.2 cm^3

Volume of die = 366.440 cm^3

Density of acrylic sheet = 1.18 g/cm^3

Density of foam board = 0.961 g/cm^3

Mass of linkage = density of acrylic x volume of linkage = 1.18g/cm^3 x 241.2 cm^3 = 284.616 g = 0.284616 kg

Mass of die = density of foam board x volume of die = 0.961 g/cm^3 x 366.440 cm^3 = 352.1 g = 0.3521 kg

Total mass = mass of linkage + mass of die = 0.284616 + 0.3521 kg = 0.636716 kg

Spring constant (k) = F/x = Total mass/Displacement

k = 0.636716 kg / 2cm

k = 0.3181421 kg/cm

Torque = Total mass x radius (length of short link) = 0.636716 kg x 11 cm = 7.003876 kg-cm

Torque with spring = 7.003876 / 0.3181421 = 2.2024767 kg-cm

Factor of Safety = 1.5

Torque x Factor of Safety = 2.2024767 kg-cm x 1.5 = 3.30317 kg-cm

60 RPM DC Motor is used

Adapter Sizing (Punching):

Operating voltage for DC Motor = 12V

Current drawn by motor at full load = 300mA

No of DC Motor = 1

Factor of Safety = 1.2

Operating Current = 1x300mA = 300mA x 1.2 = 360mA

Therefore 12V 1A Adapter is used