2.0 Pertinent Information Gathering - P-Division-2022-2023-Odd/Repo13 GitHub Wiki

1) 01FE22BCI001 Info Gathering

What is a Cookie Mould Machine?

A cookie mould maker machine is a machine used for creating mould that covers various bakery items.

How does this machine work?

-

Firstly, a cylindrical paper is put on the horizontal arm slot. Then this arm pushes the paper on the between the metal presser and cupcake metal mould.

-

Then, the metal presser presses the paper into the metal mould to give its shape to hold a cupcake.

-

Finally, the paper is given shape and passed into a container for collection

Existing solutions:

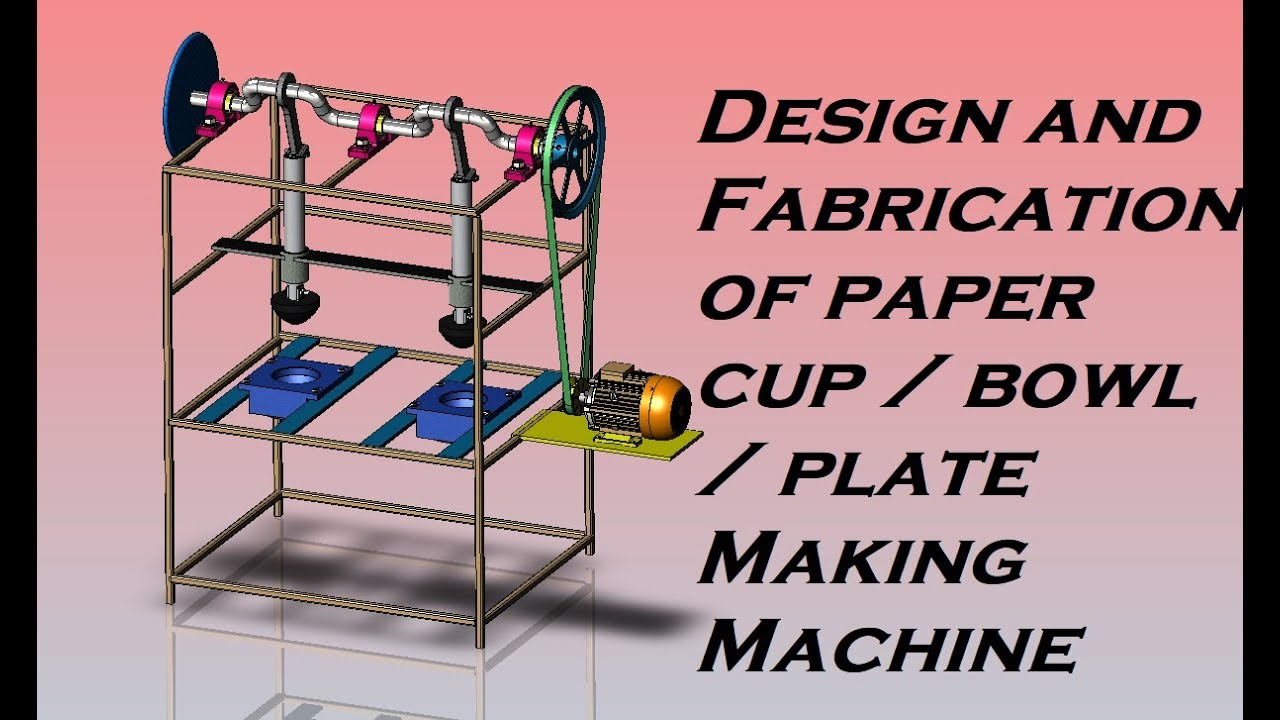

Cupcake Mould Making Machine

Mould Maker

Components:

- Cup Making Moulds

- Connecting Rods

- Base Frame

- Mounts & Joints

- Screws & Fitting

- DC Motor

- Vacuum Cup

Source:

Production line websites

YouTube

YouTube Links:

https://www.youtube.com/watch?v=IBH7OGdJNgo

https://www.youtube.com/watch?v=kuf3aPkq_WI

https://www.youtube.com/watch?v=lFRlN-BsHXQ

2) 01FE22BCI004 Info Gathering

Introduction

Crudely defined, a cookie mould maker is an automated/semi-automated machine that is used to shape the protective covering of eatables, like cookies, cupcakes and even paper cups. It reduces the time, effort and the cost of the mould making process in comparison to manual work.

Components and Parts Used

- Connectors and Actuators

- Hydraulic Cylinder

- Base frame

- Mounts & Joints

- Valves for Direction and Flow Control

- Shaping Mould(s)

- Screws and Fittings

- Connecting Rods

Sources

https://www.youtube.com/watch?v=IBH7OGdJNgo

https://www.youtube.com/watch?v=kuf3aPkq_WI

https://www.youtube.com/watch?v=lFRlN-BsHXQ

3) 01FE22BCI009 Info Gathering

Introduction

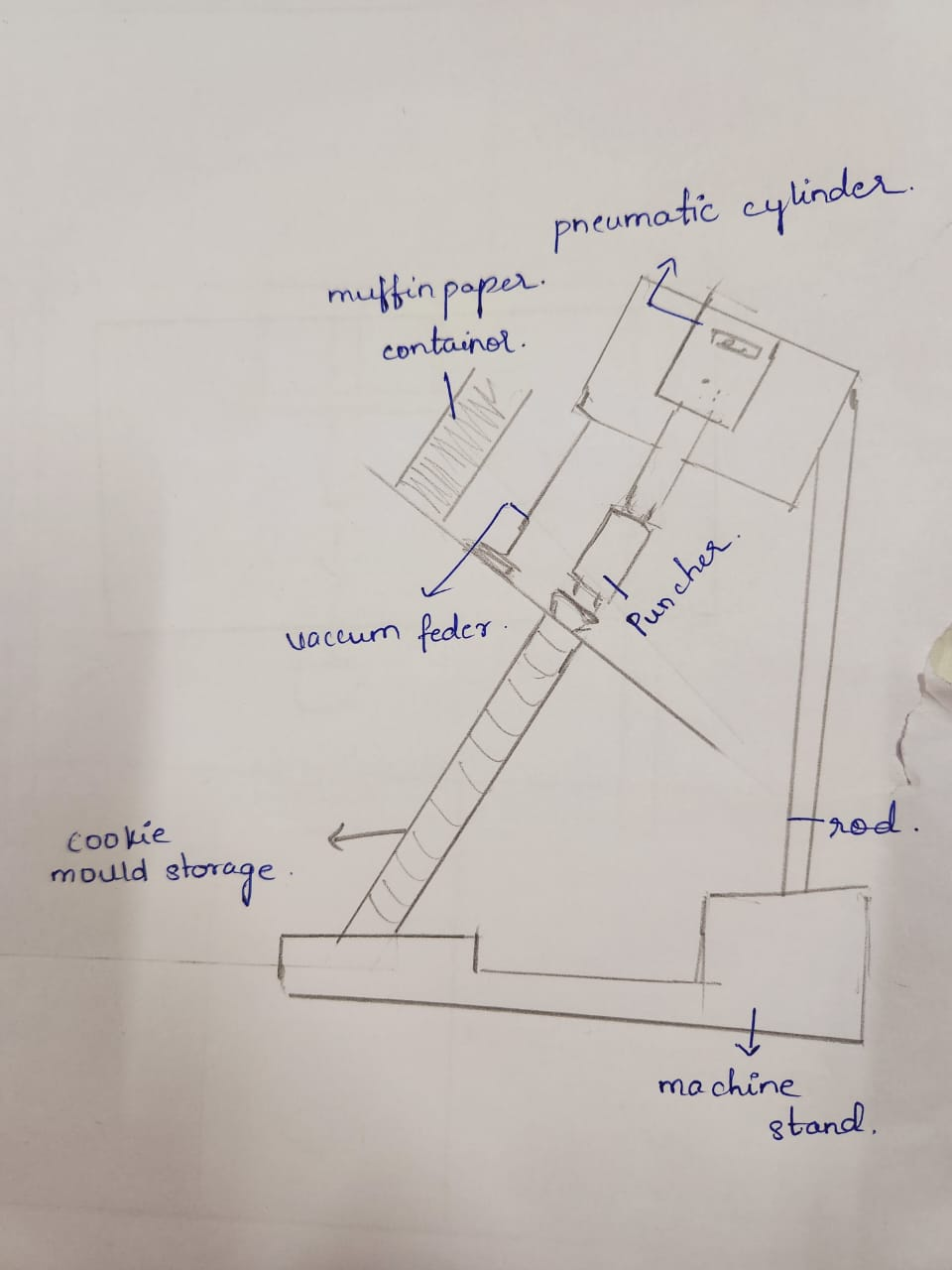

Cookie mould maker using pneumatic cylinder.

Components needed to build the cookie mould machine

- Stand

- Pneumatic cylinder

- Muffin paper container.

- Puncher

- Vaccum feder

- Rod

- cookie mould storage.

Step to build the cookie mould machine

- First step is to build a stand made steel or any material is okay until its stable and strong enough.

- Second step is to creat an impression on the Pneumatic cylinder to make the cookie moulds desired shape.

- Third step is to fix the Pneumatic cylinder on the stand.

- Fourth step is to creat another impression on the the steel slab fixed under the pnematic cylinder.

- Fifth step is to place the paper in the paper cup making block.

- sixth step is that the Pneumatic cylinder presses the paper agin the block.

- Final step , the cookie mould is ready.

What is Pneumatic cylinder??

Pneumatic cylinders (sometimes known as air cylinders) are [mechanical devices] which use the power of compressed gas to produce a force in a reciprocating linear motion.Like [hydraulic cylinders], something forces a to move in the desired direction. The piston is a disc or cylinder, and the piston rod transfers the force it develops to the object to be moved. Engineers sometimes prefer to use pneumatics because they are quieter, cleaner, and do not require large amounts of space for fluid storage.

4) 01FE22BCI013 Info Gathering