Beach cleaning robot - L-Division-2018-2019/repo11 GitHub Wiki

Introduction

Engineering exploration is one of the most creative course, it all begins with gathering the pertinent information which can reveal the facts about the problem that result in a redefinition of the problem, and creating some innovative ideas related to the existing problems in the society, which can help the lively hood.

Need Statement

Beach cleaning robot

Abstract A beach cleaner vehicle is drawn across sand.A scraper blade shaves a layer of sand and debris from the sand surface.A continuous conveyor transports the sand and debris over sifter bars within the chassis of the beach cleaner.A foraminous sifter bars within the chassis of the beach cleaner.A foraminous sifter separates debris and permits sand to fall back to the beach.The sifting process is enhanced by a system adapted to vibrate the foraminous sifter during operation of the beach cleaner.Debris is deposited in a trash basket which is hydraulically dumped[1].

Information about the existing beach cleaning products

There are many products related to beach cleaning, everyone of them has the unique designs related to the usage,area and need.There are many beach cleaning products such as Walk-behind beach cleaner,Tractor attached beach cleaner,raking beach cleaner and a tractor-pulled beach cleaner.There is a common mechanism behind all the beach cleaning machines, a sand cleaning machine,beach cleaner is a vehicle that drags a raking or sifting device over beach sand to remove rubbish and other foreign matter.They are manually self-pulled vehicles on tracks or wheels or pulled by quad-bike or tractor. Beach cleaning machines work by collecting sand by way of a scoop or drag mechanism and then raking of sifting anything large enough to be considered foreign matter,stones,litter and other items[1].

Existing solutions for beach cleaning

-

The tool which can have the conveyor belts and sharp lifting appliances can lift the trash upwards and put it into the bag which is attached to it so that it can be taken to the dumping area.

Fig.6 RF controlled beach cleaner[8]. -

Solarino Sand Beach Cleaner Robot is a particular combination between our powerful tracked mobile robot XBOT and one of its working units; it is the first ecofriendly, remote-controlled beach cleaning machine able to move both on wet and dry sandy terrain and to remove rubbish and other foreign matter. Totally electrically driven, powered by full isolated GEL batteries and also by solar energy, silent, accurate and robust, Solarino Beach Cleaner provides a comfortable and a low environmental solution for beach cleaning. It is robust since frame and tracks undercarriage are not only protected by paint, but also fully hot-dip-galvanized using both stainless steel and aluminium; the wide matched tread helps to optimizing the traction system performance both on wet and dry sandy terrains by providing a good flotation in any situation. The vibrating mechanical sifter is silent, robust and precise and its working parameters are totally configurable by using the remote transmitter. It is silent and eco-friendly because Solarino Beach Cleaner Robot is totally electrically driven and does not use internal combustion engines or idraulic systems; it uses electric linear actuators to configure the working-depth parameter and to execute rubbish unloading operations[26].

[27].

[27].

Fig.15 Solarino Beach cleaner.

- Beach cleaner BCK02A has excellent performance on beaches. The strong power of the cleaner makes it can pass through all terriens. No matter sea rocks or soft sands, the BCK02A can reach everywhere.

The BCK02A has high adapting ability. BCK02A has passed the PI test, it can be dust proof under 20 millibar, as well as water proof under 360 degree pulse of water and big waves.

BCK02A also has great developing ability, one can choose different size and different kind of cleaning machines according to the real needs.

All parameters can be customized according to customer needs. [28]

[29]

[29]

Fig.16 Beach cleaner BCK02A

Direct solutions

1) Creating a beach cleaning model

A beach cleaning machine comprises a motorised vehicle having receptacle and a compactor for compressing material in the receptacle and a collection device for collecting litter into the receptacle,the collection device.Which is controlled with the help of bluetooth(i.e remote controlled)[3].

Fig.1 Beach cleaning machine[3].

Here this system shown is a 4 wheel drive vehicle chassis equipped with a cleaning mechanism and a dirt bag for garbage collection. Two high performance, high efficiency electrical motor drives the vehicle chassis and one electrical motor drives the cleaning mechanism.chain and the sprocket based system transmits the power from the electrical motors to the wheels.The system is driven by a micro controller powered circuitry PCB.Another PCB consists of directional push buttons used to transmit directional commands through rf. The receiver circuit receives the commands and the microprocessor processes these commands to drive the motor as well as the lifter mechanism motor accordingly.The lifter mechanism consists of a chain sprocket arrangement to drive the garbage lifter[10].

Collectively these three motors can be wirelessly driven by a radio frequency based Remote control.Cleaning mechanism of this beach cleaner is also equipped with a wire mesh,which separates the beach sand from the garbage[10].

2) Man handling tool

The man handling tool is totally man dependent,whenever a person drags it it will collect all litter in it and will leave out the sand and water which has not to be taken.It is long lasting when compared to other devices, by making it RF controlled we can make it more easier to handle.

Fig.2 Man handling beach cleaning tool[4].

This man handeling tool consists of mesh designed chamber which is porous in nature and contains the rod to hold it and drag it on the surface of the sand ,contains wheels also which will help us to drag the tool easily on the sand surface. When we drag it on the sand surface it picks up all the garbage present on the surface of sand and leaves back the sand which has got into it, it can be used for underwater cleaning also as its porous in nature it will leave back water sand and tiny materials which are not to be picked.

Beach cleaning machine:

A beach cleaning machine comprises a motorised vehicle having a receptacle and a compactor for compressing material in the receptacle and a collection litter into the receptacle, the collection device[3].

Components and sub components:

- DC motors

- Arduino

- Mounts

- Bluetooth

- Wires,screws and wheels

- Chains and connecting rods

- Shaft and sprockets

- Bearing and filter

- Conveyor belts

Working of the components

DC motor

A DC motor is any of a class of rotary electrical machines that converts direct current electrical energy into mechanical energy.The most common types rely on the forces produced by the magnetic fields.Nearly all types of DC motors have same internal mechanism.either electromechanical or electronic,to periodically change the direction of current flow in part of the motor[11]. A DC motors speed can be controlled over a wide range,using either a variable supply voltage or by changing the strength of current in its field winding's.The lightweight brushed DC motor used for portable power tools and appliances[11].

Fig.8 DC motor[17]

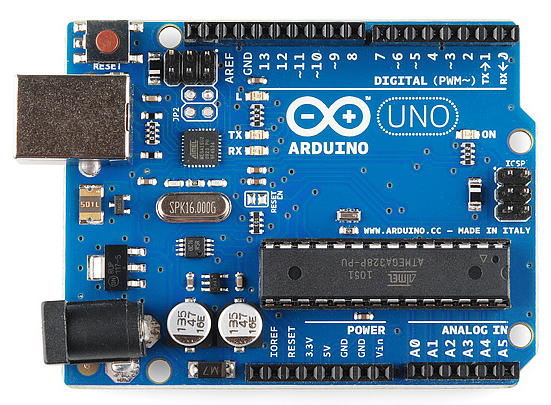

Arduino

Arduino is used for building electronics projects. Arduino consists of both a physical programmable circuit board(often referred to as a micro controller) and a piece of software,or IDE(integrated Development Environment)that runs on your computer ,used to write and upload code to the physical board[13].

Main IC is the brain of our arduino. we need to know the IC type before uploading any new program onto it.with some simple code, arduino can control and interact with a wide variety of sensors-things that can measure light ,temperature,degree of flex ,pressure,proximity,acceleration,radioactivity,humidity,barometric,pressure.An arduino has the capability of handling USB directly,code libraries are available which allow the board to emulate a computer keyboard,mouse and etc,as it has the micro controller with built-in USB[13].

Fig.10 Arduino[19]

Bluetooth

Bluetooth Controlled Robotics involves the operation of Robots in accordance with the signals sent from a smart phone using an Android Application and Bluetooth Communication. In the Bluetooth Based Robotics Workshop, serial programming of the Microcontrollers is an integral part. The workshop helps participants understand the concepts and use of accelerometer sensor, microcontrollers, and microcontroller programming in Bluetooth Controlled Robot designing[14].

Fig.11 Bluetooth[20]

Shaft and sprockets

A sprocket is a profiled wheel with teeth, or cogs,that mesh with a chain, track or other perforated or indented material.The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth[15].

Sprockets and chains are also used for power transmission from one shaft to another where slippage is not admissible, sprocket chains being used instead of belts or ropes and sprocket-wheels instead of pulleys. They can be run at high speed and some forms of chain are so constructed as to be noiseless even at high speed[15].

Fig.12 sprockets[21].

Bearings

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts[16].

Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the plain bearing, consists of a shaft rotating in a hole. Lubrication is often used to reduce friction. In the ball bearing and roller bearing, to prevent sliding friction, rolling elements such as rollers or balls with a circular cross-section are located between the races or journals of the bearing assembly. A wide variety of bearing designs exists to allow the demands of the application to be correctly met for maximum efficiency, reliability, durability and performance[16].

Fig.13 Ball Bearing[22]

Conveyor belts

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more[24].

Fig.14 Conveyor belt[25].

Table 1 Information collected by various sources[23]

| Sl.nor | Components involved | Working principle | Links |

|---|---|---|---|

| 1 | DC Motor | A DC motors speed can be controlled over a wide range,using either a variable supply voltage or by changing the strength of current in its field winding's.The lightweight brushed DC motor used for portable power tools and appliances[11]. | https://en.m.wikipedia.org. |

| 2 | Arduino | Arduino is used for building electronics projects. Arduino consists of both a physical programmable circuit board(often referred to as a micro controller) and a piece of software,or IDE(integrated Development Environment)that runs on your computer ,used to write and upload code to the physical board[13] | https://learn.sparksfun.com. |

| 3 | Bluetooth | Bluetooth Controlled Robotics involves the operation of Robots in accordance with the signals sent from a smart phone using an Android Application and Bluetooth Communication[14] | https://www.skyfilabs.com |

| 4 | Sprocket | Sprockets and chains are also used for power transmission from one shaft to another where slippage is not admissible, sprocket chains being used instead of belts or ropes and sprocket-wheels instead of pulleys. They can be run at high speed and some forms of chain are so constructed as to be noiseless even at high speed[15] | https://en.wikipedia.org/wiki/sprocket |

| 5 | Bearings | A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts[16] | https://en.wikipedia.org/wiki/bearing_(mechanical). |

| 6 | Conveyor Belts | A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems | https://en.wikipedia.org/wiki/Conveyor_belt |

Observation

-

By looking at the picture we can see that we can use simple toy mechanisms to build a new model of greater innovation and the technique used for the toy to move through electronic gadgets, and remote control mechanism.

Fig.3 Robotic toy mechanism[5]. -

Using the robotic and coding technique,which has the capability of sensing only the trash material in the surroundings but not the litter materials which can be achieved by coding.

Fig.4 Robotic and coding mechanism -

we have a man handelling beach cleaner tool,which should be draged by the person who wants to clean but if we attach it to the wheels and give a RF controller system to it it would be not less than the machines existing today in this world and more over it would be less in its cost.

fig.5 Man handelling tool[7].

-

The tool which can have the conveyor belts and sharp lifting appliances can lift the trash upwards and put it into the bag which is attached to it so that it can be taken to the dumping area.

Fig.6 RF controlled beach cleaner[8]. -

Constructing such a huge and heavy model which will be able to crush the materials and pick them up with which some useful materials can be formed and which can be used in daily lives (like trash bins).

Fig.7 Huge beach cleaning machines[9].

References

[1]. https://patents.google.com/patent/US5133413A/en

[2]. https://patentimages.storage.googleapis.com/10/90/dd/167e18ca3fdc9d/US5122412.pdf

[3]. https://patents.google.com/patent/US20050205270A1/en?q=~patent%2fUS5133413A

[5]. https://cdn-blog.adafruit.com/uploads/2016/10/RobotMissionsHero-e1476666044696.jpg)

[6]. https://i.ytimg.com/vi/S-mlmCVlXGM/maxresdefault.jpg)

[8]. (https://nevonprojects.com/wp-content/uploads/2018/08/RF-Controlled-Beach-Cleaner-Robotic-Vehicle.jpg)

[9]. (https://www.hbarber.com/rotators/images/Dual%20Surf%20Rake%20Beach%20Cleaner%20Dump.jpg)

[10]. https://nevonprojects.com>rf-controlled beach cleaner robotic vehicle

[11]. https://en.m.wikipedia.org

[12]. https://www.galco.com

[13]. https://learn.sparksfun.com

[14]. https://www.skyfilabs.com

[15]. https://en.wikipedia.org/wiki/sprocket

[16]. https://en.wikipedia.org/wiki/bearing_(mechanical)

[18].(https://www.galco.com/images/moreinfo/relay_diagram.gif)

[19]. (https://cdn.sparkfun.com/assets/9/1/e/4/8/515b4656ce395f8a38000000.png

[21]. (https://upload.wikimedia.org/wikipedia/commons/thumb/6/6a/Sprocket16.png/330px-Sprocket16.png)

[22]. (https://upload.wikimedia.org/wikipedia/commons/thumb/1/16/Ball_Bearing2.jpg/330px-Ball_Bearing2.jpg)

[23].Table.1 Information collected from various resources.

[24]. https://en.wikipedia.org/wiki/Conveyor_belt

[25]. https://upload.wikimedia.org/wikipedia/commons/2/2a/Power_transmission_belt.gif.

[26]. http://www.dronyx.com/solarino-beach-cleaner-robot/

[27].(http://www.dronyx.com/wp-content/uploads/2016/03/xbot-con-rastrello21.png)