2. Pertinent Information Gathering - J-division-2020-2021-even/Repo-07 GitHub Wiki

Automated petri plate loading machine

Automatic Petri plate filling machine loads sterilized media into it. The machine has to move petri plates to and from the loading site continuously.

As biotechnologists are finding it difficult to prepare petri plates for culturing of microorganisms or animal cell lines, there is a need to build a machine, that could load the sterilized media into it and move the petri plates to and from the loading machine.

Why automate? Automation offers a number of advantages over manual processes, not least the elimination of manual errors, standardization of protocols, and improved reproducibility and quality control. A sterile environment is of the utmost importance when dispensing media into Petri dishes and tubes, and this can easily be jeopardized during manual processes; with automation, the potential to introduce contamination is drastically reduced. Manual processes are also tedious and time consuming, and walk-away automation frees up staff to undertake other, more interesting, tasks.

Automated petri plate allows the sterilised media to be filled inti the dishes and be moved to the loading site continuously. For doing so, we require a proper dishes holder of appropriate sizes (diameters) and also we require a keypad display to enter the number of plates or the amount of sterilized media that needed to be filled into the petri plates.

The main features of this machine must be that it should fill/dispense high number of petri plates as much as possible, in a given amount of time. There should be integrated peristaltic pump which ensures precise filing of media. The media filler must have a frictionless ring and stepper motors for silent and precise operation. The smooth aluminium surface should be placed, as they are easy to clean with no holes and gaps where media can flow into. Shaft seals are installed on every moving axis to avoid media penetration into the internal components of the machine.

This petri plate filler can also be converted into a tube filler using the same vessel and little effort. Here, we can place test tubes of different diameters to fill the content, as required. The petri dish filler must be easy to handle and easy to control all the functions. They must be actively guided throughout the entire filling process. The optical dish sensors can be easily adjusted to virtually every petri dish at the user level interface level. The machine should be of minimum cost. This machine can be equipped with the UV lamp extending over the full length of the rotor where the dishes are opened during the filling process.

The petri plate filler must be a walkaway system, where it should not need the supervision of the biotechnologists all the time of its processing. The petri plate filler can also have the feature of filling media into bi and tri plates of our choice. Basically, it should have a smooth and quiet operation that is, noise operation reduced to minimum. It should also have a shaker function which ensures the optimum distribution of the media in the petri dishes. The filling can be controlled by a timer or a foot switch. It can have an option of cooling unit for rapid agar solidification and minimizing condensation.

And for the effective filling of the media into dishes, there must be IR sensor placed, which ensures no sterilized media is dispensed out of the petri plates. It should be one-touch petri dish selection – integrated database for pre-programmed petri dish dimensions. The stacking carousel of different heights must be made available according to the requirements.

Components used :

1. Microcontroller : It is an integrated (IC) device used for controlling other options of an electronic system, usually via a microprocessor unit, memory and some peripherals.

2. RTC: It’s a real time clock. Using this, we can keep a track of long timelines and count the periodicity of an input that is connected.

3. Servo Motors: They are rotary or linear actuators that rotate and push the parts of a machine with precision. Mainly used on angular or linear position and for specific velocity and acceleration.

4.Racks : It holds the petri plates or the test tubes that are used in culturing.

5. Power supply: power supply is required for the machine to move the petri plates to and from the loading sites.

6. Key pad and display: the keypad and display is required to control all the functions involved petri plates to be culturing.

7. IR sensor: The sensor is required for the proper filling of the media into the dishes as it detects the plates when placed for culturing. Its principle is that when an object comes closer to it, the infrared light from the LED reflects off the object and is detected by the receiver.

8. Speaker: The mechanical energy compresses air and converts the motion into sound energy or sound pressure level. It is essential for the updation of the process taking place.

| SI NO. | components or parts used | mechanisms/working principles identified | links |

|---|---|---|---|

| 01 | Motors (mechanical) | To run the machine precisely | www.integra-biosciences.com |

| 02 | Sensors (electronic) | Required for filling of media into petri plates | www.labmate-online.com |

| 03 | Speakers/keypad and display (electronic) | Control the function involved in culturing the petri plates | https://ayj168.en.made-in-china.com/product/vsUxcOPYZXhT/China-Automatic-Petri-Lab-Dish-Filler.html |

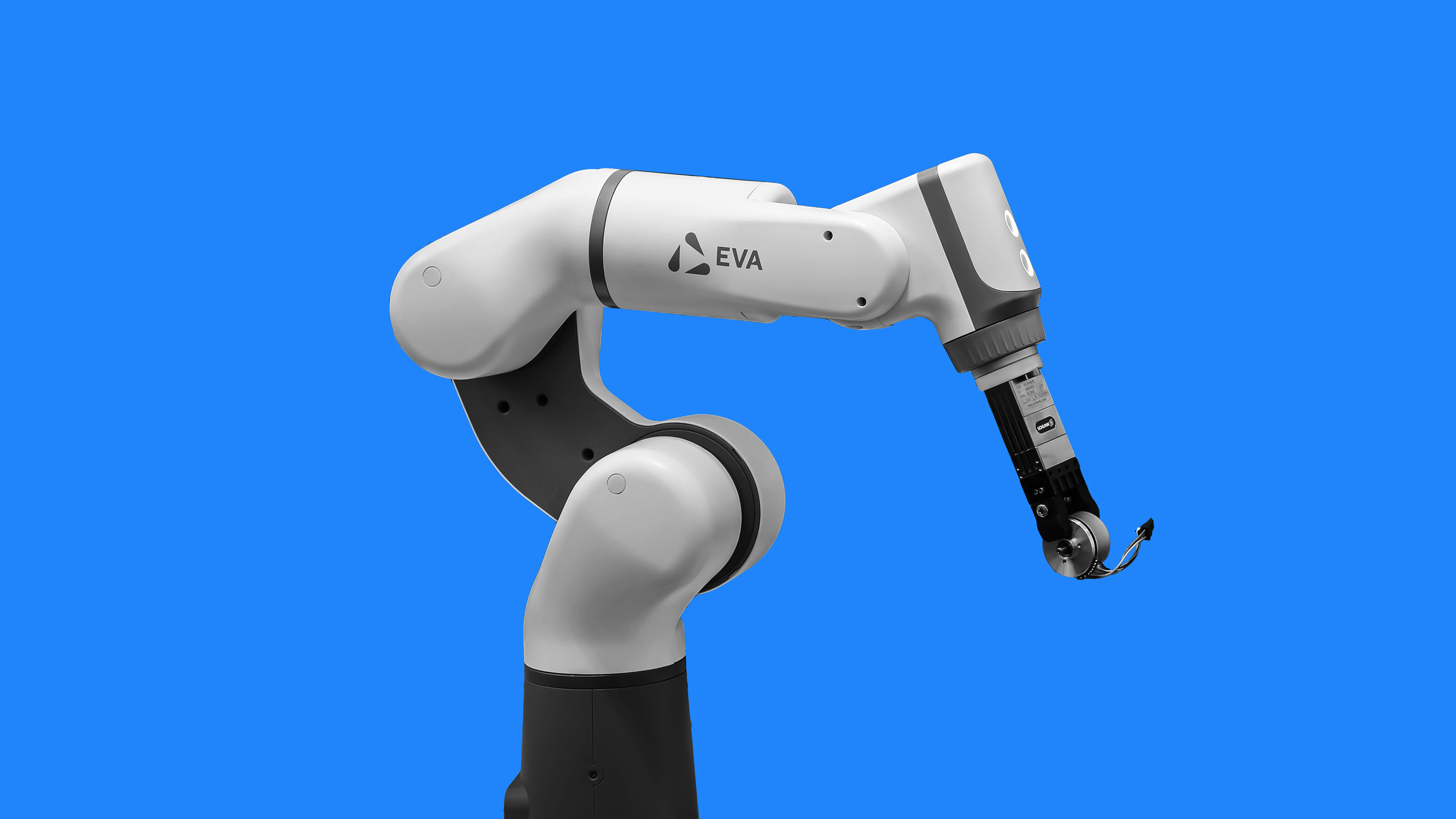

| 04 | Robotic/electric arm (electronic) or conveyer belts(mechanical) | To move the petri plates | https://youtu.be/8SC7EQCqksI |

| 05 | Racks (mechanical) | To hold the petri plates | https://www.systec-lab.com/mediafill-en/ |

| 06 | Container (mechanical) | To hold the media | https://800ezmicro.com/equipment/media-preparation/49-systec-mediafill.html |