Labware Home - HenriquesLab/NanoJ-Fluidics GitHub Wiki

Fluidic connections

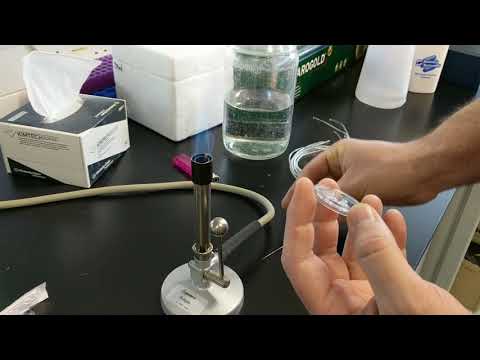

Traditional microfluidics make use of soft lythograpy. For NanoJ-Fluidics, however, we sought to make the process as simple and flexible as possible for routine use. We settled on the simplest method possible: poking holes on the lid of a cell culture dish. However, if you pierce the lid with anything sharp or cutting, you might find the lid breaks and cracks. To solve this, we use heated syringe needles, as demonstrated in the below video. The hot needle will melt the plastic while piercing it and prevent the lid from cracking or breaking, regardless of how many holes have been made.

This method allows several tubing connections to be made to a single cell culture dish. The tubing is held in place by friction, since we make the holes just a bit smaller than the outer diameter of the tubing.

Making the holes on a lid is a simple 3-step process, with a few tricks to it.

- Using a bunsen burner, heat a syringe needle until it is red hot.

- Take the heated needle and pierce the lid while the needle is hot. Do not remove the needle yet, however. If the size of the needle is too small for the diameter of the tubing, the needle can be wiggled about to increase the size. The trick to this part is to wait a few seconds before piercing the lid. The video shows a lid that was made "too fast", so a lot of the plastic gets melted. If we wait a few seconds before, however, the needle won't be as hot and won't melt as much plastic. This results in holes with a more controlled size.

- Wait for the needle to cool down and then you can remove it. This is important as you can accidentally enlarge the hole or make a line of melted plastic on the lid.

The timing for steps 2 and 3 of the process will depend on the size of the needle and the type of plastic, but it requires only a few tries until someone can become confident with the process. After the holes have been made, the tubing can then be threaded directly through the holes. We cut the ends of the tubing at an angle so they are easier to thread through (visible in the video).

Lab-ware

Below is a list of the materials we use and we know will work for you. But it is by no means definitive.

Cell culture dishes

We prefer dishes that self-lock like Ibidi dishes. This is because the tubing is held in place by the lid. If the lid is not attached, the weight of the tubing can be enough to tip it over. The self-locking dishes add a little bit of mass which helps to reduce this issue. We also prefer to image on stages that have clamps to maintain the dish and its lid in place. But some microscope stages only hold on to bottom part of the dish (like those on the Nikon Ti). Therefore, on these stages, having a self-locking lid helps to keep the lid and tubing in place.

Tubing

We use two types of tubing. One with small internal diameter for small volume syringes (1, 2 and 5 ml) and another for liquid removal as well as large volume syringes (10, 20 and 50 ml).

Small internal diameter tubing: Cole Parmer, WZ-06460-10

Large internal diameter tubing: Cole Parmer, WZ-06460-24

Side note: The difference in diameter is because there is a maximum torque the motors can apply. The larger the ratio between the internal diameter of the syringe and the internal diameter of the tubing, the more torque the motor needs to apply. So, for the large diameter syringes, the tubing needs to have a larger internal diameter or the Lego motor will not be able to push on the plunger. The upshot is that larger diameter syringes will require a larger dead volume between them and the dish.

Equillibrating temperature

Thermal drift can occur when injecting room temperature liquid into a temperature controlled chamber. This can be solved by adding some extra length to the tubing and place it coiled inside the chamber. This will allow the liquid to equillibrate with the temperature in the chamber.

Syringe needles

We use 30G syringe needles (VWR: 613-2011) for the small internal diameter tubing and 21G needles (VWR: 613-2023) for large internal diameter tubing.

Tested Syringes

We have mostly used BD plastipak as well as Terumo plastic syringes.