PSU Setup - Geowissenschaften/EXCISS GitHub Wiki

The following step by step instruction must be executed, to change some of the factory default values, to match the exciss requirements.

Required hardware

Software preparation

Install bqStudio:

BatteryManagementStudio-1.3.54.1_Build1 (sluc525u)

Update bqStudio Chemistry Database:

- download: bqStudio Chemistry Updater (Rev. EE) - ChemUpdate632 (sluc564dw)

- copy files in

Chemitryfoler to:..\TI\BatteryManagementStudio\chemistry

Update Charger definiton:

- download: Charger_1_00-bq25700A.bqz

- copy to:

..\TI\BatteryManagementStudio\config\

Update Gauge definition:

- download: bq40z50-R2 Gauging Embedded Firmware v2.11 (sluc649)

- copy:

4500_2_11-bq40z50R2.bqzto..\TI\BatteryManagementStudio\config\ - use:

bq40z50R2_v2_11_build_52.srecfor fimware update (description below)

Change bqStudio View Type

- In the

Windowmenu selectPreferences - click on

All Global Settings - under

Battery Management Studio (bqStudio) View Typechoose:Show Advanced Views

Charger

The charger IC doesn't require to be prepared. All the pre define parameters are define as hardware based values. Some parameters must be defined during runtime by the MCU.

Gauge Preparation

The gauge IC requires some preparation before first usage. Follow the step by step instruction to prepare the gauge before productive usage.

-

Connect PSU's SMBus TI EV2400 USB Adapter.

-

Power up PSU

Gauge firmware update

- Start bqStudio

- select

gaugeand click next - select

4500_2_11-bq40z50R2.bqzand clickFinish - click

OK - click

Firmware - select

bq40z50R2_v2_11_build_52.srec(mentioned above in Software preparation: Update Gauge definition) - click

Program - restart bqStudio

Gauge battery parameters

Update cell chemistry

A chemistry database update might be required to add the required chem-id(2152) (mentioned above in Software preparation: Update bqStudio Chemistry Database:)

- select chemid: 2152

- click on

Update Chemistry from Database

Update Gas Gauging parameters

-

click

Data Memory -

click

Gas Gauging -

set

Design Capacity mAh(underDesign) to:3500mAh -

set

Design Capacity cWh(underDesign) to:5089cWh(Nominal Voltage (V) * cell count * capacity(Ah) * 100 =

3,635V * 4 * 3,5Ah * 100 = 5089cWh)

-

set

Design Voltage(underDesign) to:14540mV(Nominal voltage (mV) * cell count)

-

set

Chg Current Threshold(underCurrent Thresholds) to:30mA -

set

Term Voltage(underIT Cfg) to:12000mV(3000mV * cell count)

-

set

Load Mode(underIT Cfg) to:1(constant power)

Advanced Charge Alorithm parameters

- click

Data Memory - click

Advanced Charge Alorithm - set

Charge Term Taper Current(underTermination Config) to:50mA

Considerations

We need to ensure:

- Taper Current > Chg Current Threshold > Quit Current

- Dsg Current Threshold > Quit Current

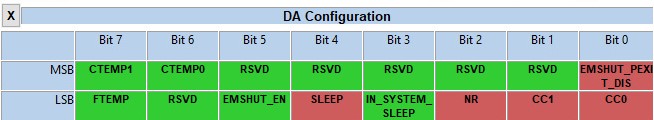

Gauge change DA Configuration (0x0012 -> 0x0117)

SLUUBK0A page 150

-

click

Data Memory -

click on

Settings -

click on

DA Configuration(underConfiguration) -

toggle

NR(red)NR (Bit 2) = 1 (Use PRES in system detection: NON-REMOVABLE mode)

-

toggle

CC0(red)CC1, CC0 (Bit 1,0): Cell Count set to CC1 = 1, CC0 = 1 (Cell Count: 4 cell)

-

toggle

EMSHUT_PEXIT_DIS(red)EMSHUT_PEXIT_DIS (BIT 8) = 1 (Prevents usage of SHUTDN pin as exit option)

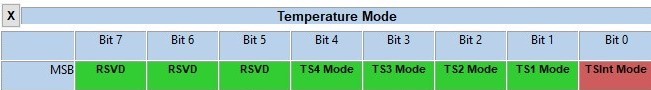

Gauge change Temperature Mode (0x0004 -> 0x001)

SLUUBK0A page 149

-

click

Data Memory -

click on

Settings -

click on

Temperature Mode(underConfiguration) -

toggle

TS2 Mode(green)TS2 Mode (Bit 2) = 1 (Cell temperature)

-

toggle

TSInt Mode(red)TSInt Mode (Bit 0) = 1 (FET temperature)

Gauge change Temperature Enable (0x0006 -> 0x01f) 1e

SLUUBK0A page 148

-

click

Data Memory -

click on

Settings -

click on

Temperature Enable(underConfiguration) -

toggle

TSint(red)TSint (Bit 0) = 1 (Enable internal TS)

-

toggle

TS3(red)TS3 (Bit 3) = 1 (Enable TS4)

-

toggle

TS4(red)TS3 (Bit 4) = 1 (Enable TS4)

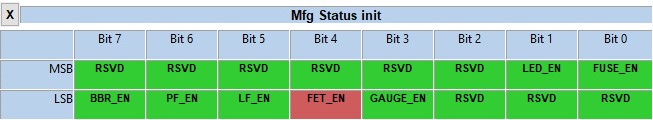

Gauge Mfg Status init (0x0000 -> 0x0010)

SLUUBK0A page 161

-

toggle

FET_EN(red)FET_EN (Bit 4) = 1 (All FET Action: Enabled)

-

Power cycle PSU

Gauge change FET Options (0x0020 -> 0x0024)

SLUUBK0A page 138

- click

Data Memory - click on

Settings - click on

FET Options(underConfiguration) - toggle

OTFET(red)

OTFET (Bit 2) = 1 (CHG and DSG FETs will be turned off for overtemperature conditions)

Gauge Calibration

Explained at the end of this page

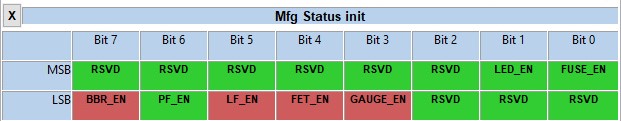

Gauge Mfg Status init (0x0010 -> 0x00b8)

SLUUBK0A page 161

This step proberbly should be done AFTER learning cycle, but we did perform the lerning cycle later. Refer to: TI Support Forum: BQ34Z100-G1: Learned Status

-

click

Data Memory -

click on

Settings -

click on

Mfg Status init(underManufacturing) -

toggle

BBR_EN(red) BBR_EN (Bit 7) =1 (Black Box Recorder: Enabled) -

toggle

LF_EN(red) LF_EN (Bit 5)= 1(Lifetime Data Collection: Enabled) -

toggle

GAUGE_EN(red) GAUGE_EN (Bit 3) =1 (Gauging: Enabled) -

Power cycle PSU

Gauge Perform Learning Cycle

This is described in: 4024.LearningCycleOverview.pdf

Please note: “The learning cycle guide doesn't 100% apply to bq40z50-R1 in terms of some of the flag names. It's more a procedure guide. RDIS is RUP_DIS flag.”

Source: TI Support Forum: BQ40Z50-R1: Problems performing a Learning Cycle

Gauge Calibration (needs to be performed earlier, see above)

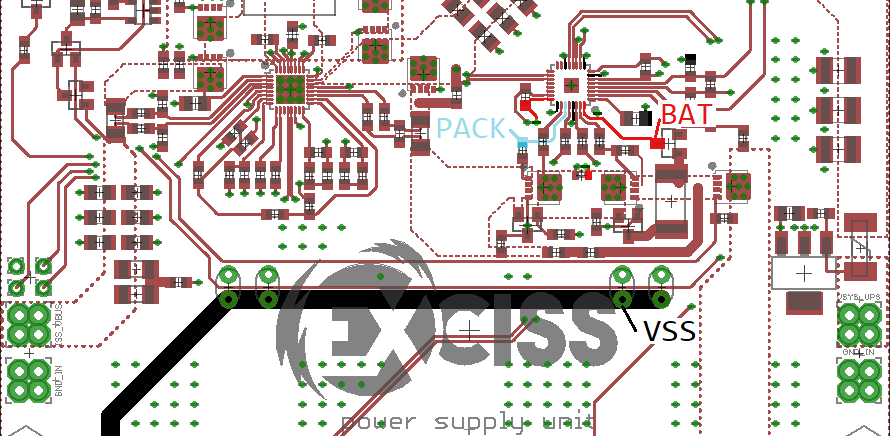

Voltage Calibration:

- connect 4 100 Ohm resitors as battery dummys

- apply 16V between VSS and 4P

- Measure Cell 1 Voltage and enter value in calibration field

- tick

Calibrate VoltageCheckbox - Measure BAT pin voltage and enter value in calibration field

- tick

Calibrate VoltageCheckbox - measure PACK pin voltage and enter value in calibration field

- tick

Calibrate VoltageCheckbox - Click

Calibrate Gas Gauge

Current Calibration

- set DC load to 900mA and connect to PSU output

- connect 5V to PSU input

- disconnect EV2400

- start bqStudio

- click on

Charger - click on

Next - click on

Charger_1_00-bp2700A.bqz - click on

Finish - reconnect EV2400

- click on

Read Register - set Input Current Register to 0mA

- restart bqStudio

- Click on

Calibration - Enable DC load

- Disconnect 5V at PSU input

- enter measured current (should be 900mA) into

Applied Curennt(example: -900) - tick

Calibrate CurrentCheckbox - Click

Calibrate Gas Gauge

Temperature Calibration

- apply know temperature to all sensor

- enter temperature in

Tempearturefield - Hit

CalibrateCheckbox - Click

Calibrate Gas Gauge