Pertinent Information - F-Division-2018-2019/Team-5 GitHub Wiki

PICK AND PLACE

Pertinent information

Introduction

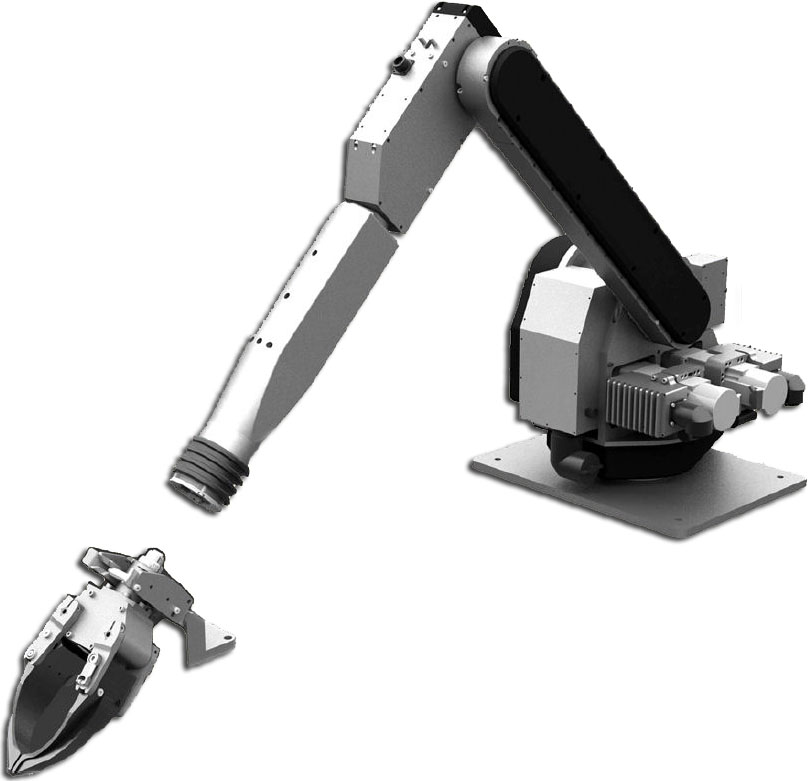

fig(1.1)

An order uses industrial robots to automate applications throughout your production line to save time and money. Industrial robots reduce waste and produce higher quality products with continuous precision. Robots can also handle the most tedious and dangerous manufacturing applications to keep your workers safe, healthy and motivated. Robot Work integrates new and reconditioned robot system for wide spectrum of robotic application. Our robot integration experience and knowledge are a great benefit to our customers. We want your production line to run as smooth and efficiently as possible and can identify the best robot solution for your specific application requirements. Each industrial robot application requires unique end of arm tooling, specific reach and payloads, and flexibility. Robot work has a large robot and work cell inventory from name brand robotic companies that allows us to integrate quickly.[2]

Existing models

fig(1.2)

Author:

Publisher: PTI Date: February 21, 2018

Image source: Massachusetts Institute of Technology

Received from URL: https://indianexpress.com/article/technology/science/robot-system-can-pick-and-sort-objects-study-5073147/[8]

fig(1.3)SCARA co-bot

Author: Publisher: Kawasaki Robot

Date: -

Received from URL: https://www.google.com/search?q=robot+that+sense+and+carries+the+object+to+respective+bins+in+cargo+warehouse&source=lnms&tbm=isch&sa=X&ved=0ahUKEwjmiK70hprdAhUUbo8KHUgODfMQ_AUICigB&biw=1536&bih=747#imgrc=P9_DR0vqtlgAKM:[9]

fig(1.4)

Author: Julian Smith

Publisher: Scientific American

Date: -

Received from URL: https://www.scientificamerican.com/article/robot-learning/[7]

fig(1.5)

Author:

Publisher: Tanya M. Anandan, Contributing Editor Robotic Industries Association

Date: -27/07/2018

Received from URL: https://www.robotics.org/content-detail.cfm/Industrial-Robotics-Industry-Insights/Force-and-Tactile-Sensors-Give-Robots-a-Feel-for-the-Job/content_id/7337[6]

fig(1.6)UP1

Author: Kartik Tiwari Publisher: Tully Foote

Date: January 14, 2016

Received from URL: http://www.ros.org/news/robots/mobile-manipulators/[5]

PICK AND PLACE ROBOTIC ARM TRANSMITTER BLOCK DIAGRAM

The transmitting end consists of push buttons which are used for sending commands to the receiver for controlling the movement of the robot in forward, backward, left or right directions. The receiving end consists of four motors that are interfaced to the micro controller. Among these four motors, two motors are used for the arm and gripper movement of the robotic arm kit and the other two motors are used for the robotic vehicle movement. http://www.edgefx.in/wp-content/uploads/2014/12/Pick-N-Place-Robot-Robotic-Arm-Receiver-Block-Diagram-by-Edgefxkits.com_.jpg[3]

The radio frequency transmitter acts as RF remote control, this RF technology with proper antenna can be used over a range of 200 meters. The receiver circuit decodes the encoded data received from the transmitter before feeding it to another microcontroller for driving DC motors driver IC to perform the necessary operation. The main advantage of this robotic arm is its soft catching arm that is designed to avoid extra pressure on the suspended object for safety reasons. In future, this robotic arm project can be enhanced by interfacing this kit with a wireless camera such that the person controlling the robot can view the operation of the arm and gripper remotely.[2]

WORKING OF PICK AND PLACE ROBOTIC ARM PROJECT

The simple steps can be followed for designing a working pick and place robotic arm using major hardware components such as motors, switches, battery, piece of metal and other discrete electrical and electronic components. These steps of how to make a robotic arm includes building wheels of robot using strips and motors and arm gripper.[3]

COMPONENTS

1.Manipulator:

Just like the human arm, the robot consists of what is called a manipulator having several joints and link

2.End-effector:

the base of the manipulator is fixed to base support and its other free end, the end-effector is attached. The end-effector is expected to perform tasks normally performed by the palm and finger arrangements of the human arm.

the end-effector could be thought of as the "hand" on the end of the robotic arm . There are many possible end-effectors including a gripper, a vacuum pump, tweezers, scalpel, blowtorch, welder, spray gun, or just about anything that helps it do its job. Some robots can change end-effectors and be reprogramed for a different set of tasks. End effectors may consist of a gripper or a tool. When referring to robotic prehension there are four general categories of robot grippers, these are:

Impactive – jaws or claws which physically grasp by direct impact upon the object.

Ingressive – pins, needles or hackles which physically penetrate the surface of the object (used in textile, carbon and glass fibre handling).

Astrictive – suction[vague] forces applied to the objects surface (whether by vacuum, magneto- or electroadhesion).

Contigutive – requiring direct contact for adhesion to take place (such as glue, surface tension or freezing).[10]

3.The Locomotion Device:

In case of human beings the power for the movement of the arm, the palm and fingers is provided by muscles. For the robot the power for the movement(locomotion) is provided by the motors. The motors used for providing locomotion in robots are of three types depending on the source of energy: Electric, Hydraulic or Pneumatic.

4.The controller:

The digital computer (both the hardware and the software) acts as a controller to the robot. The controller function in a manner analogues to the human brain, with the help of this controller, the robot is able to carry out the assigned tasks. The controller directs and controls the movement of the manipulators and the endeffector.in other words, the controller controls the robot.

5. Sensors:

Without the data supplied by the sense organs, the brain would be incapable of intelligence. In other words the controller(computer) of the robot cannot do meaningful task, if the robot is not with the components analogues to the sense organs of the human body. Thus, the fifth and the most important component of the robot is the set of sensors. Sensors are nothing but the measuring instrument which measures quantities such as position, velocity, force, torque, proximity, temperature etc.[4]

6.CONVEYOR BELT:

A conveyor belt is the carrying medium of a belt conveyor system. A belt conveyor system is one of many types of conveyor system. A belt conveyor system consists of two or more pulleys, with an endless loop of carrying medium-the conveyor belt- that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors. Those in general material handing such as those moving boxes along inside a factory and bulk material handing such as those used to transport large volumes of resources and agriculture materials, such as grains, salt, coal, sand, overburden .

6. MOTOR

A DC motor is any of a class of rotary electrical machines that converts direct current electrical energy into mechanical energy. The most common types rely on the forces produced by magnetic fields. nearly all types of DC motors have internal mechanism, either electromechanical or electronic , to periodically change the direction of current flow in part of the motor.

DC motors were the first type widely used, since they would be powered from existing direct-current lighting power distribution systems. A DC motor's speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of the current in its field widings. Small DC motors are used in tools, toys, and appliances. The univer1sal motor can operate on direct current but is a lightweight brushed motors used for portable power tools and appliances. Larger DC motors are used in propulsion of electric vehicles, elevator and hoists, or in drives for steel rolling mills. The advent of power electronics has made replacement of DC motors with AC motors possible in many applications.

| sl.no | electrical parts | mechanical parts |

|---|---|---|

| 1 | DC motor | Conveyor |

| 2 | Sensors | links |

| 3 | Digital Display | storage unit |

| 4 | Arduino | collective bins |

MECHANISM:

-

Linkage 2)Robotic 3)Vacuum

|

SOURCES:

Cargo mover prototype

- https://youtu.be/P2r9u4wkjcc

- https://youtu.be/Mmsnl_G-_V4

- https://youtu.be/iDWMTnky2Ec

- https://youtu.be/K-2HvJijF-o

- https://youtu.be/tf7IEVTDjng

REFERENCES:

[1] www.i.stack.imgur.com http://www.edgefx.in/wp-content/uploads/2014/12/Pick-N-Place-Robot-Robotic-Arm-Receiver-Block-Diagram-by-Edgefxkits.com_.jpg

[2]Automation in warehouse development Author: Roel of Hamborg: Jacques Velried

[3]www.edge.fx.in/how-to-make-robotic-arm-along-working/

[4]www.yourarticlelibrary.com

[5] http://www.ros.org/news/robots/mobile-manipulators/

[7] https://www.scientificamerican.com/article/robot-learning

[10]www.wikiwand.com