9 SPRINT_3 - EngineeringExploration20182019B/Repo10 GitHub Wiki

3-D Model

BILL OF MATERIALS

| SL.NO | PART NAME | MATERIAL WITH WHICH THE PART IS MADE | DESCRIPTION ABOUT PART | QUANTITY REQUIRED |

|---|---|---|---|---|

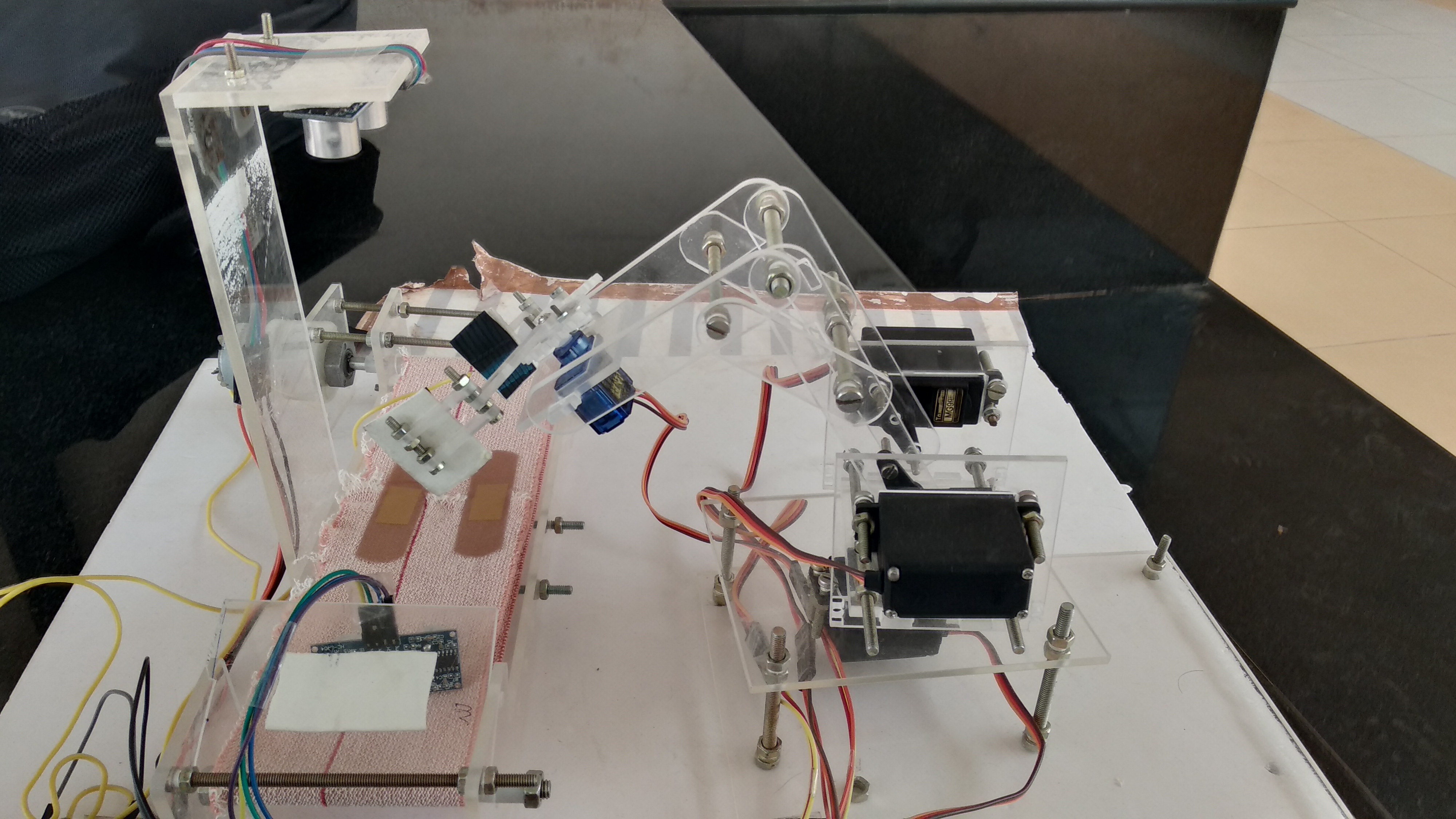

| 1. | gripper | acrylic sheet,3mm | which is used to pick the objects | 2 |

| 2. | gripper holder | acrylic sheet,3mm | which is used to connect or hold the gripper | 2 |

| 3. | base | acrylic sheet,3mm | which is used to hold the whole body of the robot | 1 |

| 4. | arm | acrylic sheet,3mm | which is connected to gripper holder | 2 |

| 5. | gears | acrylic sheet,3mm | which helps in movement of the gripper | 2 |

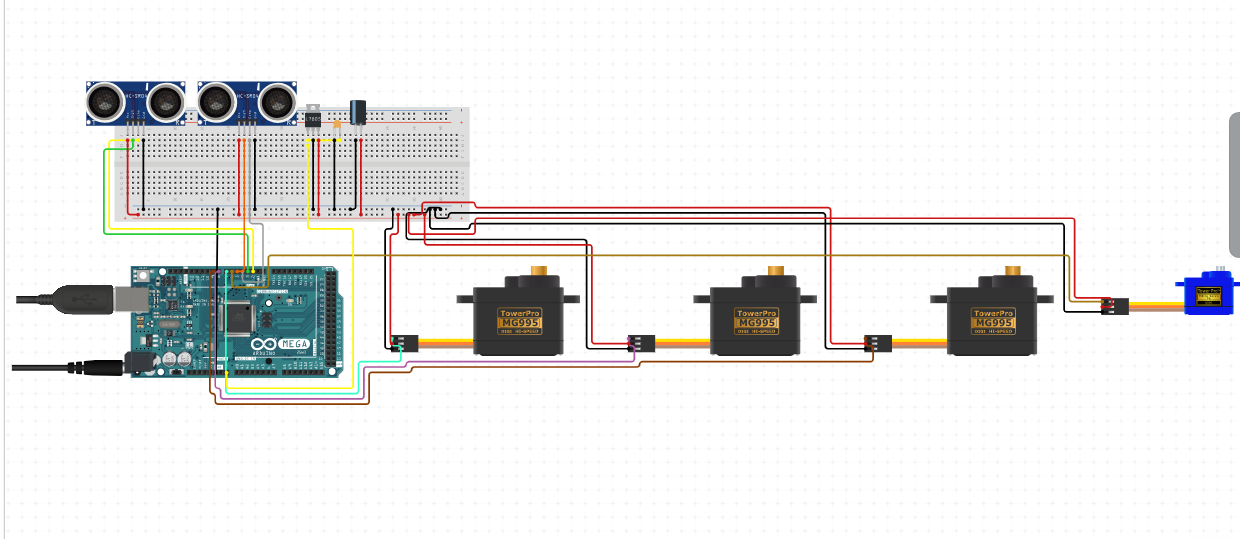

CIRCUIT DIAGRAM

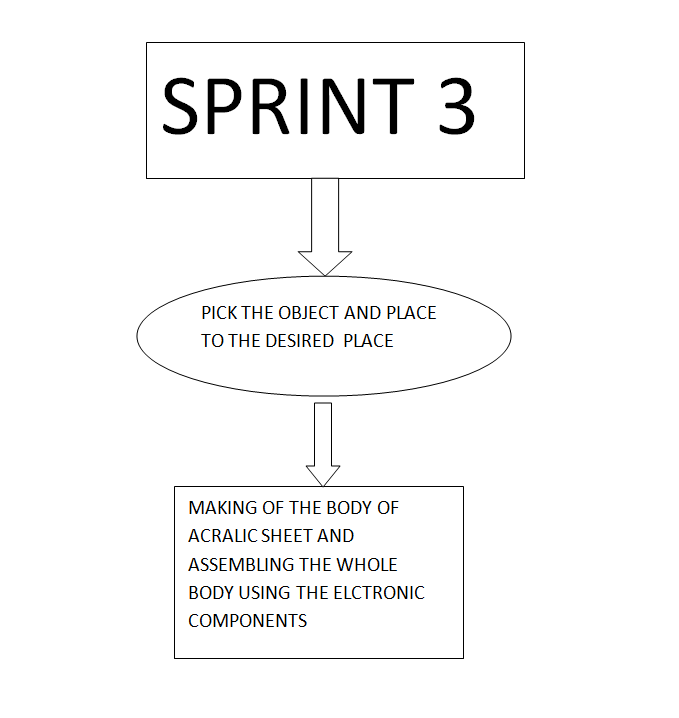

FLOWCHART

TEST PLAN

At the end of the sprint 3,we had expected our integrated conveyor belt along with the ultrasonic sensors and sorting boxes powered by servo motors to perform the desired function of sorting three cubical boxes of different dimension and place at different angles as written in the arduino code..

FABRICATED SYSTEM

TEST RESULTS

Here in this phase we have to build the main body and base of the bot using acrylic sheet .And assemble them and insert electronic components wherever needed.

STATEMENT OF EXPENDITURE

| SL NO. | Item with description | Quantity | Price in Rs. |

|---|---|---|---|

| 1. | Ultrasonic sensors | 2 | 120*2=240 |

| 2. | Crepe bandage | 1 | 180 |

| 3. | Adaptor 12v,5v | 1 | 500 |

| 4. | Foam board,3mm | 1 | 80 |

| 5. | Dc motor,10rpm | 1 | 250 |

| 6. | Servo motors | 3 | 1200 |

| 7. | Arduino mega | 1 | 950 |

| 8. | Insulating tape | 1 | - |

| TOTAL-- | -------------------- | -------- | 3750 |