6 VIRTUAL IMPLEMENTATION. - B-Division-2022-2023-Odd/Repo-11 GitHub Wiki

6.1 FLOW CHART:

6.1.1 Sensing process.

6.1.2 Folding Process

6.1.3 Despensing process.

6.2 Circuit Diagram.

6.2.1 Sensing Process.

6.2.2 Integrated Part of Cloth Folding Machine.

6.3 MOTOR SIZING.

1.Fliping board 1: l=0.6m b=0.15m t=0.005m V=lbt v1=0.60.150.005 v1=0.00045m^3

Mass=volumedensity m=0.000450.048 m=0.000216kg/m^3

Force=mg Force=0.0002169.8 Force=0.0021168 N

F=umg F=0.60.0002169.8 F=0.00127008 N

T=Fr T=0.001270080.3m T=0.000381024 N/m

2.Fliping board 2 : l=0.3m b=0.25m t=0.005m V2=lbt V2=0.000375m^3

Mass=volumedensity mass=0.0003750.048 mass=0.000018 kg/m^3

Force=mg Force=0.0000189.8 Force=0.0001764N

F=umg F=0.60.0000189.8 F=0.00010584N

T=Fr T=0.0001058430cm T=0.003175 N/m

Tmax=T*1.5 Tmax=0.0047628 N/m

T=0.0047628*9.8 T=0.04667544 N/m

2.Flipping board 2:l=0.3m b=0.25m t=0.005m V2=lbw V2=0.30.250.005 V2=0.000375m^3

Mass=vdensity mass=0.0003750.048 mass=0.000018kg/m^3

Force=mg force=0.0000189.8 force=0.0001764N

F=umg F=0.6*0.0001764 F=0.00010584N

T=Fr T=0.0001058430 T=0.0031752 N/m

Tmax=T1.5 Tmax=0.00317521.5 Tmax=0.0047628 N/m

T=Tmax/g T=0.0047628/9.8 T=0.0004864N/m

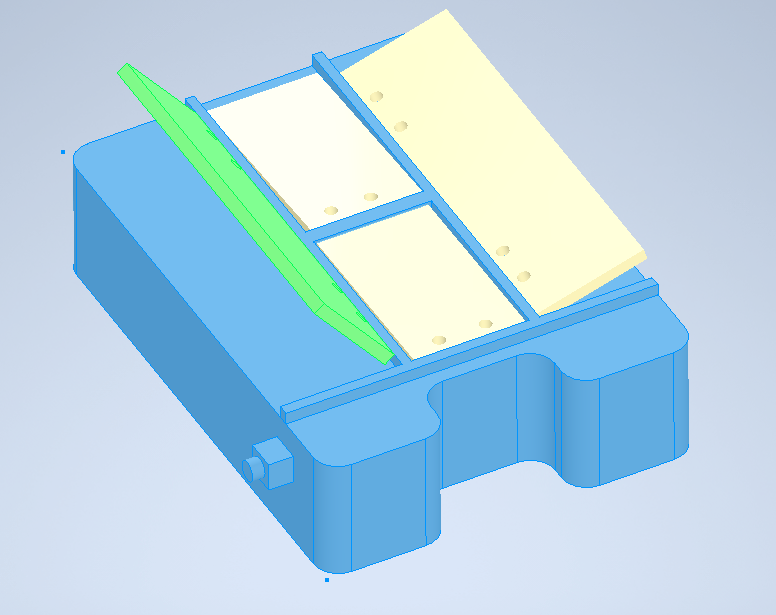

6.4 3D-MODELLING.

CLOTH FOLDING MACHINE.

6.5 BILL OF MATERIALS.

| SL.NO | PART NAME | MATERIAL WITH WHICH THE PART IS MADE UP OF | DESRIPTION ABOUT PART | QUANTITY REQUIRED |

|---|---|---|---|---|

| 01 | Hinges | steel | 4cml | 6 |

| 02 | Flipping boards | Foam sheet | l=60cm,b=15,thick=5mm | 2 |

| 03 | single standard wire | - | - | |

| 04 | L-clamps | steel | - | 12 |

| 05 | clips | - | - | 4 |

| 06 | Insulation tape | - | - | 1 |

| 07 | Nut and Bolts | Steel | - | 40 |

| 08 | Foam sheet | 60x60x10m | 1 | |

| 09 | Foam sheet | 30x15x5mm | 2 | |

| 10 | Foam sheet | 25x30x5mm | 2 |